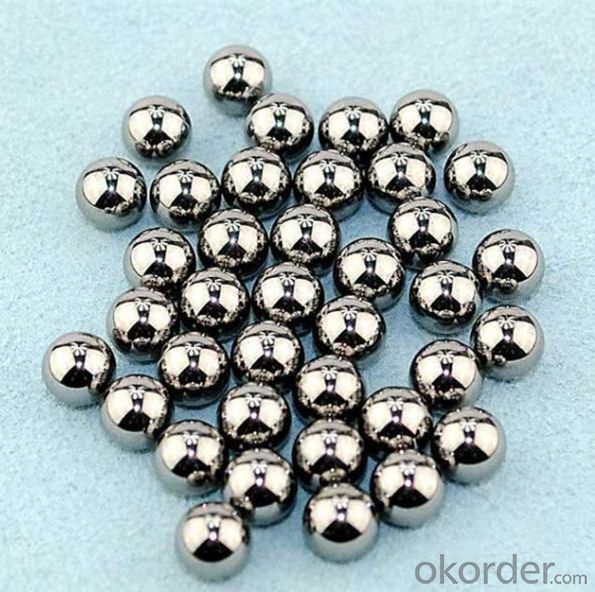

SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

The detail of AISI304 stianless steel ball

Hereare many kinds of stainless steel balls, AISI 304, AISI 316, AISI 316L, AISI 420, AISI 420C,

AISI 440, AISI 440C.AISI 304 steel ballshave no good hardness but offer good corrosion resistance,

they offer good resistance to atomospheric corrosion, dyes, food processing, valves, sex products and so on.

AISI 304 stainless steel ball in our factory :

Minimum diameter: 2mm

Best precision :G100

Hardness :HRc25-39

| Product | SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball |

| Material | stainless steel |

| Brand | SAIGE |

| Percision | G100 |

| Hardness | HRC25-39 |

| Surface | zerodefect, bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Package | four small boxes within a carton of 20kg |

AISI 304 chemical Composition

| Materials Standard | Chemical Composition (%) | Hardness | ||||||

| JIS SUS304 (AISI304) (Din X5CrNi18-10) | C | Cr | Ni | Si | Mn | P | S | HRC25-39 |

| <0.08< td=""> | 18.00-20.00 | 8.00-10.50 | <1.0< td=""> | <2.0< td=""> | <0.045< td=""> | <0.030< td=""> | ||

PACKAGING

Type 1 : Plastic bag + box + carton + wooden pallet

Type 2 : Plastic bag + carton + wooden pallet

Type 3 : Our package :export cartons, steel drums, wooden pallets

- Q:What are the different types of steel tubes and their uses?

- There are several types of steel tubes, including seamless, welded, and ERW (Electric Resistance Welded) tubes. Seamless tubes are made without any welding or joints and are used in high-pressure applications like oil and gas pipelines. Welded tubes are manufactured by bending and welding steel plates or strips and are commonly used in construction, automotive, and furniture industries. ERW tubes are made by passing a high-frequency current through the metal, producing a welded seam, and are used in structural and mechanical applications. Furthermore, there are specialized types of steel tubes such as square, rectangular, and round tubes, each serving specific purposes in various industries.

- Q:What is the difference between hot rolled and cold rolled steel?

- The main difference between hot rolled and cold rolled steel lies in the manufacturing process. Hot rolled steel is produced at high temperatures and is characterized by a rougher surface and less precise dimensions. Cold rolled steel, on the other hand, is manufactured at room temperature and undergoes additional processing, resulting in a smoother surface, tighter tolerances, and improved mechanical properties.

- Q:How is steel used in the manufacturing of elevator systems?

- Steel is used in the manufacturing of elevator systems primarily for its strength and durability. It is used to construct the frame, support beams, and shafts of the elevator, providing structural stability and ensuring the safe transportation of passengers or goods. Additionally, steel is used in the fabrication of elevator doors, car panels, and other components due to its excellent resistance to wear and tear.

- Q:What are the different types of steel cables and their uses?

- There are several types of steel cables, each designed for specific applications. Some common types include galvanized steel cables, stainless steel cables, and carbon steel cables. Galvanized steel cables are coated with a layer of zinc to prevent corrosion, making them suitable for outdoor and marine environments. Stainless steel cables are highly resistant to corrosion, heat, and chemicals, making them ideal for applications in harsh conditions such as in the aerospace or chemical industry. Carbon steel cables are strong and durable, commonly used in construction, automotive, and manufacturing industries. Overall, the choice of steel cable depends on the specific requirements of the application in terms of strength, corrosion resistance, and environmental conditions.

- Q:What are the challenges faced in the welding of steel products?

- There are several challenges faced in the welding of steel products. One of the main challenges is the potential for distortion or warping of the steel during the welding process. Steel has a high thermal conductivity, which means it can quickly absorb and distribute heat. This can lead to uneven heating and cooling, causing the metal to deform. Another challenge is the presence of impurities and contaminants on the surface of the steel, such as rust, oil, or paint. These impurities can negatively affect the quality of the weld and make it more difficult to achieve proper fusion. Additionally, the high carbon content in some types of steel can make it more prone to cracking and brittleness during the welding process. Proper pre-cleaning, selection of appropriate welding techniques, and careful control of heat input are crucial in overcoming these challenges and producing high-quality welded steel products.

- Q:What are the properties of tool steel for cutting applications?

- Tool steel is a type of high carbon steel that is specifically designed for cutting applications. It possesses several important properties that make it suitable for this purpose. Firstly, tool steel has excellent hardness, which enables it to maintain its cutting edge even under high-stress conditions. Additionally, it has exceptional wear resistance, meaning it can withstand repeated use without dulling or chipping easily. Tool steel also exhibits high strength and toughness, allowing it to withstand the forces and impacts involved in cutting operations. Finally, it has good heat resistance, which prevents the steel from losing its hardness or becoming too soft during the cutting process. Overall, the properties of tool steel make it an ideal choice for various cutting applications.

- Q:What are the different types of steel wire ropes and their uses in offshore drilling operations?

- There are various types of steel wire ropes used in offshore drilling operations, including drilling lines, sandlines, and guy wires. Drilling lines are high-strength ropes designed to support the weight of the drill string and facilitate drilling operations. They are commonly used to hoist heavy equipment and maintain tension during drilling. Sandlines, on the other hand, are smaller diameter wire ropes used to lower and retrieve tools and equipment into the wellbore. They are primarily utilized for well servicing operations such as swabbing, wireline logging, and well cleanouts. Guy wires are used to provide stability and support to offshore drilling structures, ensuring they remain upright and resist external forces like wind and waves. These ropes are typically employed in the construction and maintenance of offshore platforms and drilling rigs. Overall, steel wire ropes play a vital role in offshore drilling operations by providing strength, reliability, and flexibility for various tasks, ranging from hoisting heavy loads to maintaining structural integrity in challenging offshore environments.

- Q:What are the advantages of using steel wire ropes?

- There are several advantages of using steel wire ropes. Firstly, steel wire ropes have high strength and durability, making them suitable for heavy lifting and pulling tasks. They can handle high loads and provide excellent resistance to wear and tear. Secondly, steel wire ropes have excellent flexibility, allowing them to be used in various applications and easily maneuvered around corners and obstacles. Thirdly, steel wire ropes have a long lifespan, requiring less frequent replacements compared to other materials. Lastly, steel wire ropes have high resistance to corrosion, making them suitable for outdoor and marine environments.

- Q:What are the different types of steel forgings and their applications in the oil and gas industry?

- There are several types of steel forgings used in the oil and gas industry. Some common types include carbon steel forgings, stainless steel forgings, and alloy steel forgings. Carbon steel forgings are widely used due to their high strength and durability. They are commonly used in various applications such as valves, fittings, flanges, and pipelines. Stainless steel forgings are preferred for their corrosion resistance properties. They are commonly used in equipment and components that come in contact with corrosive substances, such as pumps, valves, and heat exchangers. Alloy steel forgings are known for their enhanced mechanical properties, including high strength, toughness, and resistance to wear and corrosion. They are commonly used in critical components such as drill bits, wellheads, and downhole tools. Overall, steel forgings play a crucial role in the oil and gas industry, providing reliable and efficient solutions for various applications, ensuring safe and efficient operations in this demanding sector.

- Q:What are the applications of steel in the wastewater treatment industry?

- Steel has various applications in the wastewater treatment industry. It is commonly used to construct durable and corrosion-resistant tanks, pipes, and other infrastructure for holding and transporting wastewater. Steel also plays a crucial role in the fabrication of screening systems, sedimentation tanks, and clarifiers. Additionally, steel is utilized in the production of specialized equipment such as pumps, valves, and chemical dosing systems, which are vital for efficient wastewater treatment processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SUS304 Steel Shot 2mm-15mm Chemical Product Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords