supplying different kinds of carbon fiber tube, light weight carbon fiber tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

3k China manufacturer carbon fiber tube

1.UV ressistance

2 non-magnetic elctromagnectic

3. enviromentally safe

Material Comparisons -

What are the benefits?

Our composite tubing, and in particularly our carbon fibre tubes, have significant advantages over most materials in terms of mechanical properties. The table opposite shows comparisons with other common materials.

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

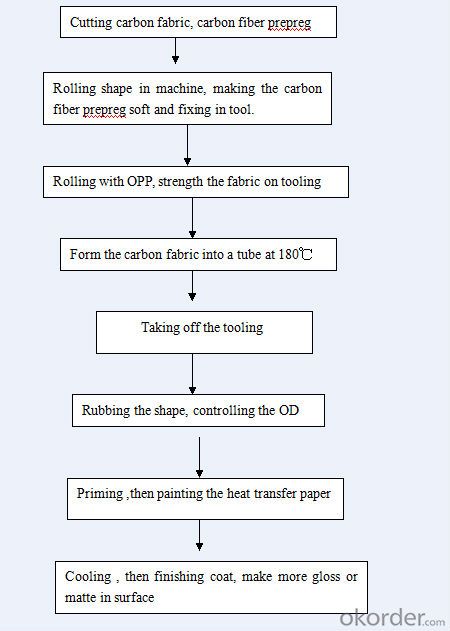

Manufacturing Process -

How are the tubes made?

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube

Marine

With over 60 years of collective marine experience we have a significant insight to this industry. This, coupled with our vast knowledge of composites, is invaluable given the diverse nature of composite marine applications.

We produce tubing for all types of marine applications, from small dinghy tiller extensions, paddle shafts, and spars up to one-off tubing for large yacht masts.

The flexibility of our manufacturing process is one of our distinctive qualities in this area:

Able to make tapered tubing which is ideally suited for mast applications.

We can make oval tubing often sought after for masts or booms requiring differential properties in different axes.

Tubes are made with epoxy resin systems which have virtually zero water absorption making them more suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

We have in-house paint facilities and are able to finish tubes with UV stable paint systems, protecting the tubing against inevitable long exposure to the elements.

photos:

We have established a considerable presence within the automotive industry supplying companies from mainstream car manufacturers to niche motorsport organisations.

We supply the majority of Formula 1 teams starting on the grid this season

We are at the forefront of composite innovation.

Experience handling and stocking very high tech materials.

Other automotive projects include:

Exhaust sleeves for both cars and motorcycles

Pit equipment

Suspension struts

Chassis members

- Q:For picture: hydraulic pipe joint M30*2H-G3/4

- Order number ten 1CG-30-22One side is the M thread, and the other is the pipe threadIt's no use looking at the picture. It's just an ordinary joint seat.

- Q:Right, me and my bf went for a walk and i text my friend and then left my phone on a wall. right next to the wall were gardens, 4 kids were on a trampoline staring at us. when i got home i realised i had forgotten my phone. i ran back to the spot and it was gone, but the children weren't in the garden. we rang it over and over, once someone answered made a screaching sound and hung up the phone. we then went to knock on their door and ask if they had seen it, they said no. now i still dont have my phone, is there anyway i can track it? where i last had it wasnt far away. it has now died, so when we ring it, it goes straight to voicemail. HELP?!?!

- judging from the name of the hand shake i am guessing its a very rough handshake that breaks your bones? lol

- Q:car alarm just goes off.car has problems as it is.

- The rush of water through the pipes loosens corrosion that is on the inside of pipes.

- Q:The clothes in Sims 3 are abnormally shiny reflective, unlike realistic material which would be particularly dull (Unless it was silk or plastic or chainmail lol)I was wondering if anyone knew of a fix or mod for this 'problem'?

- Dorms have a system where the floor RA checks the area after a smoke detector indicates a problem on the main panel, and notifies the HR whether or not to set off the Horns/strobes. If a pull station is pulled it will set off the alarms instantly. The activation of a sprinkler head will set off the alarms instantly.

- Q:i went to the pool one time after soccer and forgot my bathing suite. i went swimming w/ my tank and shorts on. haha :)

- I speak of personal experience. Is that OK? i) Withholding salary increments and promotion because of personal prejudice base on religious belief. ii) Refusing to grant an increase in salary because of employee honesty. Working for a certain firm as stores manager, I had a lot to do with railway deliveries. Once they incorrectly delivered a drum of pipe fittings which had no address on. I weighed the drum and contacted other firms who bought from the same supplier. I found the correct firm and had the railway collect the fittings - value about $2000.00 - and deliver the drum to the rightful owners. In time the railway personnel asked if I would be able to assist them in the identifying of such unaddressed items. I agreed. On one occasion they sent 9 drums (Est. value $15 00.00 - $20 000.00) for me to identify. The manager of our firm and the accountant saw these on the platform, before I had checked them. He demanded that I tell the railway that all the fittings were ours. There was no manner that the railway personnel would be able to establish the truth. I refused, weighed the drums, and allocated them accordingly. (The other firms were impressed, my manager was not) I was a new employee and after 6 months I approached the Manager with regards to an increase in salary. He refused point blank. I reminded him that a person willing to steal for him, would also be prepared to steal from him. This fell on deaf ears. I was obliged to resign. I could not find other suitable employment, so I started a carpet cleaning business. I was in business about 2 weeks when I was asked to clean that company's office carpets after hours. I suggested I quote for the job before doing the work, the reply was That's not necessary, you won't cheat us. I was handed the keys to the offices and stores and left with my staff to do the work without supervision of any sort. My bill was paid without question. Strange, don't you think?

- Q:A firefighter friend of mine has this question. If they had a tank 8'diam x 13' long with a 6 diam line from it down to the ground, what would the flow be when they open the valve? The bottom of the tank would be 11' off the ground, it is a gravity fed system. Assume two 90s for fittings, standard cs pipe (if required), I don't need it to the thousandth of a gpm :)a) What is the flow (gpm) from the tank when full?b) What is the flow (gpm) from the tank with 1 of level?c) What is the time to empty the tank completely (starting from full)?Thanks all.

- because we are INSIDE the space time universe . we can only do mathematical Imagination of what it might really be Einstein develops concepts that are based on very advanced mathematics and imagination dimensions are not just what we see but mathematical varialbes like ( x,y, z, t, p, q, r ) math equations can have as many dimensions as the mathemetician needs for the problem there are some people who have theories that require 11 dimesnions to describe the universe. that does NOT mean the theory is correct only that IF it is a good description of what Really is, then it takes 11 variables to describe it it is almost impossible for most people to understand ( including me) they would be no more than Harry Potter magic EXCEPT he makes very specific predictions about the orbit of Mercury, the light from distant stars that pass close to the sun ( we can only see them during and eclipse when the bright sun is blocked) and an explanation of energy and mass that does predict Atomic bombs there is a saying: Mass tells space how to bend and bent space tells Mass how to move sounds cute but what does it mean?

- Q:do they remove the tooth? will he be able to drive back? Will he be able to talk immediately after it? thanks

- I doubt you can. The US alone in the world persists in using IMPERIAL (that's pertaining to the BRITISH empire of course) measures even after we Brits ( who invented them) got smart and went metric - except for beer in pints - that would have been going too far. There may be a progressive US manufacturer switched on to the changing world order outside your shores, or maybe not. Give up the contract to a European company, save yourself some grief.

- Q:What are the names of all types of hydraulic pipe couplings?

- Welding type, sleeve type and flared type, according to the function of many kinds of joints, such as: the end of the straight joint and straight joints, three joints, elbow, with movable nut joint, hinge joint, plug, adapter etc..

- Q:POLL: How much would an unused set of rubber sheets (queen size) go for on ?

- FirstWhen you are putting everything together, make sure the joints are clean and free from dirt and debris. Good Luck!

- Q:Poll: Have you ever worn a pair of safety goggles and laughed when you looked at yourself in a mirror?

- I am a fairly good 'home-defense' plumber and have redone both the supply and drain plumbing in two bathrooms in our present house - all code-compliant and properly inspected. The supply-side, using Pex shark-fittings from a good copper riser took me about 4 hours to do to have it make sense and getting valves where they should be and with good access. The drain side, using a hubless fitting to a good main riser then transitioning to PVC took an additional 4 hours, not including access, repair and clean-up. My plumber would have charged me $1,500 for the lot + supplies (he provided the inspection and checked my work) but I still would have had to do the repairs and clean-up. Given that I paid just over $300 for the supplies (shark fittings are not cheap), and with his mark-up, I am guessing about $2,000 would have covered that work. After access (most of the real work) the actual plumbing was remarkably simple and all with plenty of good clearance. The only tricky part was using the chain-breaker to insert the new Y-fitting into the main riser. Your mileage may vary.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

supplying different kinds of carbon fiber tube, light weight carbon fiber tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords