Supply Fashion Mineral Fiber Ceiling Supply Fashion Mineral Fiber Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling) Description

Mineral fiber acoustic ceiling is a high-grade interior decorative material. It has undergone the process of burdening, forming, drying, cutting, surface finishing and spray coating after being added with additive. As the high-grade interior decoration material for suspended ceilings, the product is applied to elegant interior design of high-class buildings such as hotels, restaurants, gymnasiums, office buildings, shopping malls, studios, computer rooms, airports, station, factories, hospitals and home decoration.

Advantages

1.Sound absorption and noise reduction

2.Damp-proof, Anti-sagging

3.Fire-resistant

4.Safe and environment friendly

5.Elegant and fashionable

2,Main Features of the (Mineral Fiber Ceiling)

Color: White, Black

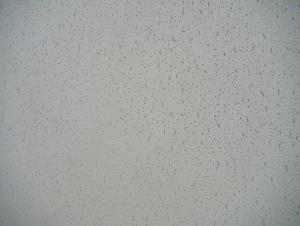

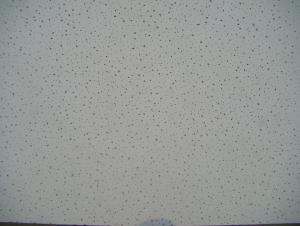

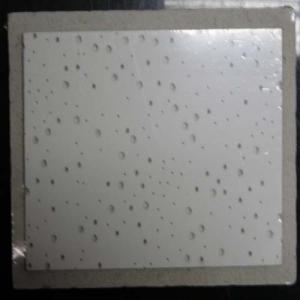

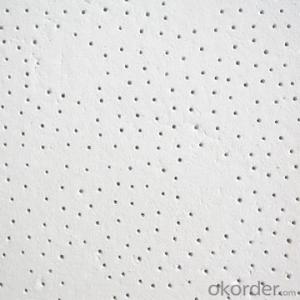

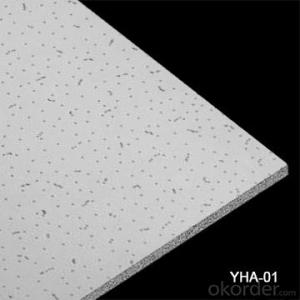

Pattern available: Astro series, fissured seriers, pinhole seriers, sand seriers, etc.

Density: 240-280 kgs/m3

Noise reduction coefficient (NRC):0.55

Light Reflectivity: 0.85

Fire Resistance: non-combustible, Class A as per ASTM E 84

Humidity Resistance (RH): 90%

Recycled Content: 63%

3,(Mineral Fiber Ceiling) Images

4,(Mineral Fiber Ceiling) Specification

Loading

Metric system | British system | Thickness | Packing | QUANTITY M2 / 40HQ |

Actual size(mm): 595x595/595x1195

Nominal size(mm): 600x600/600x1200 | Actual size(mm): 603x603/603x1213 605x605/605x1213 618x618/618x1243

Nominal size(mm): 610x610/610x1220 625x625/625x1250 | 12mm | 12PCS/CTN | 5520m2 |

13mm | 12PCS/CTN | 5010m2 | ||

14mm | 10PCS/CTN | 4600m2 | ||

15mm | 10PCS/CTN | 4400m2 | ||

18mm | 10PCS/CTN | 3500m2 |

5,FAQ of (Mineral Fiber Ceiling)

Remark:

Ceiling tiles could be loaded with T grids together in one container.

Anti-Sagging: No sagging, wrapping and delaminating

Environmental: No radiation, does not any harmful substances

Fire-resistant

Safe and environment friendly

Elegant and fashionable

- Q:How to install the decorative panels on the backcourt of BYD

- Generally push directly, it is recommended to look at the instructions

- Q:What is a decorative plate?

- It is a kind of building material used for decoration materials.

- Q:How to bend the acrylic decorative plate

- If the size requirements, you can first use wood to do a mold, bending on the reliable, the shape and size is better.

- Q:What is the cabinet of the decorative plate

- Decorative board should be the cabinet door, paint, blister, UV grain gold and so on some of the columns of the decorative door

- Q:How to remove the roof of ordinary decorative panels

- Kitchen ceiling removal Note: From the above description, it seems that the removal of the original ceiling in the kitchen is quite simple, but if you do not notice some details in the demolition process, it may damage the keel or other, which naturally will affect its second decoration, kitchen What do you need to pay attention to during the ceiling removal process? Take a look at how the nine home network is described for you! 1, the ceiling in the demolition need to take into account the original ceiling of the equipment and facilities within the safety level, need to avoid the demolition of the work of other kitchen to the normal use of the kitchen. In principle, the need to avoid damage to the ventilation and exhaust flue, and the original internal wires and water pipes are needed to avoid. 2, in the kitchen ceiling demolition need to know that the decoration of the ceiling must be consistent with the overall style of the kitchen, so that it can achieve a beautiful effect. 3, in the kitchen ceiling demolition should take into account the safety of its roof, especially in the use of more than 20 years when the kitchen demolition of the ceiling, because of its original building structure has begun to aging, coupled with the original ceiling decoration Decoration requires a large number of holes, so that the local load-bearing capacity decline.

- Q:Transparency and acrylic panels are almost decorative boards but the plates are lighter than acrylic and can you use slices with plane trims?

- The current market and its transparency similar to the purchase of the plate, and can use the plane trim the board are: (PVC, PC, PU,) and nylon and other sheet, please note that the transparency of the board is usually hard, The amount of feed should be less to prevent the side of the repair is not smooth uneven consequences.

- Q:How to install aluminum alloy decorative panels?

- Aluminum alloy decorative plate varieties, specifications and colors by the design Lai Ding, generally by the vertical installation of the board on the wall. Install the aluminum alloy decorative panels of the wall to be done in advance 15mm thick 1: 3 cement mortar leveling layer. To be cement mortar leveling layer after hardening, 500mm per hole in the wall drilling, aperture of about lOmm, in order to plug the steel expansion bolts. Ready to keel, keel can be cold-formed actinized keel or aluminum alloy keel, keel height is appropriate 60mm, width is appropriate 30mm wall thickness 2.5mm. Punch holes in the keel. When the keel is installed, insert the steel swivel bolt into the wall and drill the keel Hole into the bolt, add nuts and washers, tighten the nut, the keel fixed to the wall. The keel should be installed horizontally. Keel installation by checking the correct, you can install the aluminum alloy plate to the keel up. Aluminum alloy decorative plate fixed on the keel method can be used M4 × 6.5 aluminum alloy pull rivets (plus steel card) or use M4 × 15 tapping screws. Aluminum alloy decorative panels should be installed vertically, the board and the keel contact, at least have a pull rivets or tapping screws fixed.

- Q:Farm small courtyard of the kang kang skirt with what decorative plate good

- To ask the decorative board which is strong Jin Ke Ma * metal exterior decorative decorative panels easy to install labor hours, the price of preferential policies, large amount of money, moisture and drought, fire and flame retardant security, life comparable to days

- Q:How to remove the sounds of a car A pillar decorative plate

- First pull the door side of the strip, Teana car A pillar decorative plate without screws with a word screwdriver from the edge slowly pry open. It is best to remove the screw carefully, easy to damage the inner board, use a special tool disassembly.

- Q:Artificial texture of bark texture texture

- Small area or space is relatively small with the general operation of the use of wood, the use of wood trowel construction of imitation tree dermatoglyphic effect

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Supply Fashion Mineral Fiber Ceiling Supply Fashion Mineral Fiber Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords