Supplier of High Alumina Brick For Casting Iron/Steel/Alloy

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

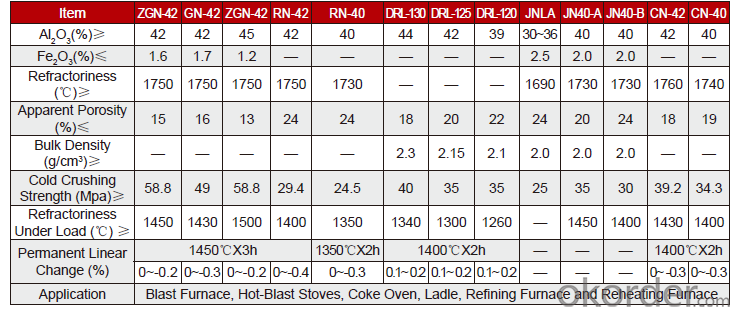

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

- Q:How to adjust the temperature in the 160 meter tunnel kiln?

- Increase will reduce the amount of fuel added to the kiln, then the temperature will change.

- Q:What's the price of clay bricks?

- Heavy clay bricks can be divided into ordinary clay brick, clay brick and low creep dense clay brick, used for lining materials in blast furnace, hot blast furnace, boiler, glass kiln, lightweight clay brick is mainly used for thermal insulation function, you will see is used where. If you want to buy the clay brick can go to Henan to see Kang Hui refractories.

- Q:What is the advantage of the ceramic fiber material compared with the refractory brick?

- Ceramic fiber material is heavier than refractory bricks, property of machinery operation, low heat capacity, and has high anti-stretchability and good thermal shock resistance, low thermal conductivity make its thermal insulation effect is ten times than refractory brick, it won't has crack in sudden coolness and heat, and the construction is much easier than that of refractory brick, not delaying the production.

- Q:What are the differences between sintered bricks and refractory bricks?

- Sintered bricks belong to a type of refractory bricks.

- Q:Do you use ceramic as offal material for refractory bricks?

- Use special clinker of bauxite with high alumina as main ingredient, pulp, K2O < 0, the main component is Al2O3 which is more than 18%, it is a kind of neutral refractory material, pyrophyllite fine powder doesn't need refractory brick production process, Fe2O3 < 1, grinding - mixing - molding - sintering - packaging - delivery. A.3%.3%, Fe2O3 < 0, molding and calcined from bauxite or other raw materials with high content oxides, combined with clay, K2O < 0.5%; 3: 2, raw materials 1; 4: 325 mesh.0%:

- Q:is it good to use firebricks to preserve the heat of rto furnace? Is there any other good ideas?

- Operating noise is very low, having a very strong chemical stability: The thermal conductivity is lower than 0 at normal temperature, it not only reduced the cost of the project of RTO furnace, but keeps the indoor heat dissipation heat better and reduce noise pollution. the temperature of RTO furnace surface is low after using the ceramic fiber lining to keep the heat, thereby reducing the addition of auxiliary fuel : ceramic fiber has a good thermal shock resistance: The dosage form of HLGX-589 and HLGX-312 ceramic fiber material is shown in figure RTO furnace thermal insulation material. C, good thermal shock resistance, without reserving expansion joints, ensure the lining intact, not easy to be affected by the harsh combustion atmosphere inside the RTO furnace, can deal with the temperature changes caused by periodic replacement of RTO furnace inlet. The furnace is new energy-saving furnace developped recent 30years that used for eliminating harmful exhaust gas caused by steel or paint spraying. it has long service life, high chemical stability, no heat preservation precedent for refractory bricks; B, good heat insulation effect.

- Q:Why can't gravity retaining walls be made of clay bricks?

- The masonry of gravity retaining walls, of course, takes into account compression problems, and the use of clay bricks requires consideration of compression calculations and service life.

- Q:Why limit sintering brick first and develop new wall material?

- The common brick used in the sintering brick will be used to borrow soil from the farmland, which will lead to the degradation and abandonment of the land. The clay belongs to the cultivated land, and protects the cultivated land in order to protect the precious land resources.

- Q:What is the sintering of non clay bricks?

- Unfired bricks are bricks used to build walls relative to sintered bricks.

- Q:What is the size of mechanism brick and general refractory brick?

- The ordinary refractory brick is 230mm long, 53mm thick; red brick is 240mm long, 115mm wide, 65mm thick,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Supplier of High Alumina Brick For Casting Iron/Steel/Alloy

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords