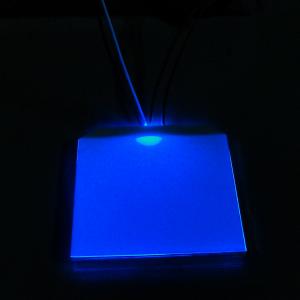

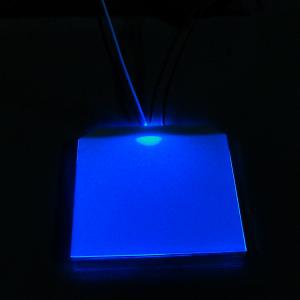

Superslim RGB LED Backlight

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature

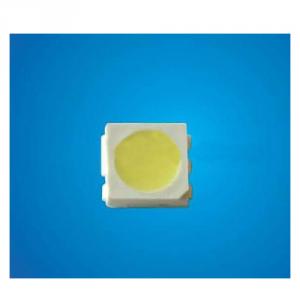

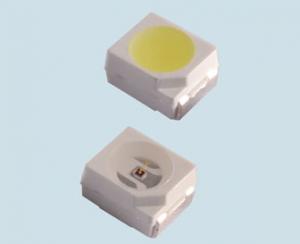

Using ultra higher brightness SMD0603 led.

Three colors available for one led backlight.

PCB with pins for convenient assebly and soldering to the main PCB.

Good uniformity and consistency.

Lower power consumption and long lifespan.

Our Services

1-Customized logo is acceptable

2-Changing the shape, color is acceptable

3-Develop on artwork & development is acceptable

4-Assistant on artwork development is acceptable

Before Orders

If possible, please tell us what's the purpose for using it, so that we can recommend you the best package. Of course with best price to you!

Any other request, please feel free to let us know.

SAMPLES are avaiable before order.

OEM & ODM service is also avaiable

Our R&D department have more than 20 professional and technical personnel.We had help customers produce many OEM products for American Market,Germany Market and UK Market.

QC(Quality Control)

QC Team:More than 20 professional and technical personnel.

Material: Strictly control of material using, meet international requested standards.

Semi-finished Products Inspection: Product inspection before 100% finished. Such as Visual Inspection, Leak Testing, Comprehensive Safty Test and so on.

Production Line Test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test before products are packed and loaded

Packaging & Delivery

Package:

Using suitable carton package as per goods situations.

Shipping via express,air or sea as per customer's requires.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q:Patch LED beads can be bought in what place?

- If you don't want to constantly change with it, suggest you go to OSRAM, Nichia, Corey, Taiwan Tongjia enterprise authorized agency purchase.

- Q:How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- More attention is paid to the lamp with waterproof and the installation of a solid in the outdoor installation, outdoor installation often adopts the mode of fixed card slot, need to cut and connected place, and indoor installation, just need another with waterproof glue, waterproof effect to consolidate the connection point.

- Q:Patch LED light does not flash, why?

- Hit the meter on the buzzer and measure the patch individually. If the flash is a patch, the light goes off.

- Q:The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- Shunt split current series split voltageIs your single lamp voltage rated voltageIn addition to the red and green LED lights, the voltage is between 2 and 2.4, and the other colors are 3 to 3.6V

- Q:What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q:Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q:Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- The pressure drop of the blue light is greater than that of the red light and the green light. If the series connection is the same as that of the green light and red light, the current limiting resistor will tend to dim

- Q:What is the difference in performance between the LED plug-in and the LED patch?

- No difference, because the core of the two is the same, are diode PN junction, but no packaging, the production process is a little different

- Q:0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- LED patch: 0603, 0805, 1206, 1210, 5050. The 0603: conversion to metric is 1005, that of the LED element length is 1.0mm, width is 0.5mm. The trade is abbreviated as 1005, and the English name is 0603. The 0805: conversion to metric is 2125, that of the LED element length is 2.0mm, width is referred to as the 2125 inch 1.25mm. industry, it is 0805. The 1206: conversion to metric is 3216, that of the LED element length is 3.2mm, width is 1.6mm. The trade is abbreviated as 3216, and the English name is 1206. The 1210: conversion to metric is 3528, that of the LED element length is 3.5mm, width is 2.8mm. The trade is abbreviated as 3528, and the English name is 1210. The 5050: This is a metric called, said that the LED element length is 5.0mm, width is 5.0mm. Industry abbreviation 5050

- Q:What is patch SMD-LED?

- SMD LED is the surface mount light emitting diode. It is a solid state semiconductor device that converts electricity directly into light. The heart of LED is a semiconductor wafer, one end of which is attached to a bracket, one end is negative, and the other is connected to the positive electrode of the power to encapsulate the entire wafer with epoxy resin.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Superslim RGB LED Backlight

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products