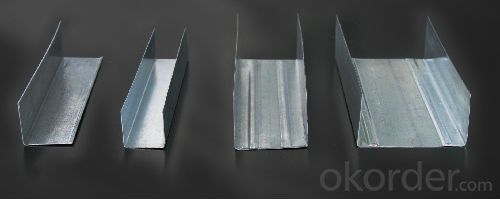

Stud Chinese Drywall C Channel Metal Stud Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

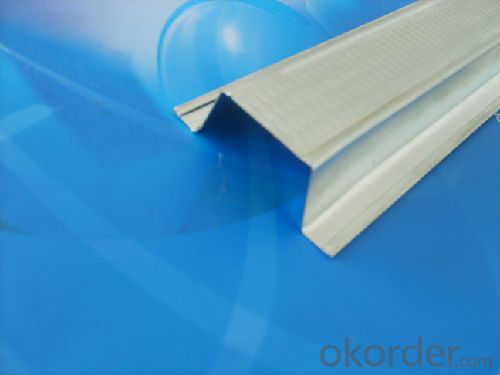

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building, bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall partition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size

6.Color:Silver white

7.Shap:U and C shap

8.Used with paper faced gypsum board or other products

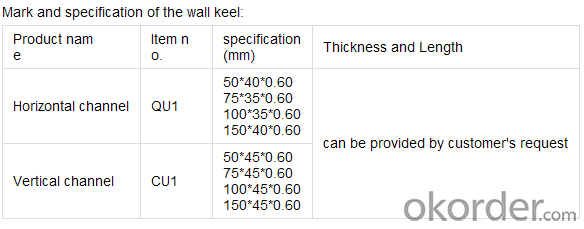

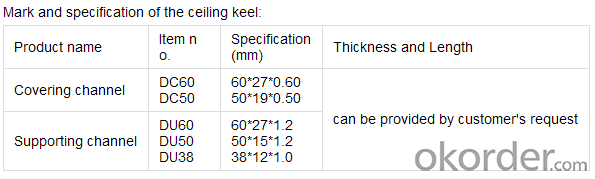

Product Specifications:

Images:

- Q:How to construct double - sided double gypsum board partition wall

- Installation of vertical keel, light steel vertical keel. Keel must be vertical, vertical keel inserted at both ends along the top keel and along the keel, adjust the vertical and positioning accuracy, with a core pulling rivets fixed.

- Q:What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite wall wall thickness of only about 175px, compared to the ordinary wall of about 300px, thin wall more space to save space, the estimated 110 square meters of the room, the use of light steel keel inorganic composite board Wall, can save about 1.6 square meters of space, so that the house to maximize the use of more spacious and comfortable space.

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q:Light steel keel partition wall how to paint

- Light steel keel structure, to find the location of the keel, use a long self-tapping screws, forced into the screw. So that it can be stable.

- Q:Light steel keel wall and wood which low cost

- Do with the wall, then, certainly with light steel keel production is better. As for the cost, can be used to do the wall of the board, it should be relatively thick, so that its price will be more than the price of gypsum board, and then the cost of light steel keel equivalent.

- Q:Light steel keel wall can be installed sliding door

- How can not press ah. It is estimated that you are afraid of wood that you fooled you And your door is too big to shrink it. The normal door is 800. Get so much useless. Now the light steel keel wall is too much. How can we press the door.

- Q:Is it possible to use a hollow brick or a 95 brick?

- With hollow bricks, because it is relatively light, will not cause the floor cracking. In fact, there are many other wall materials, including light steel keel gypsum board, steel mesh, etc., both light, but also save the space as usual when you decorate the brick wall should be used 1/2 brick wall, if the hollow brick Do, the wall width of the brush with 120 thick, the main advantage is the weight of light is generally 95 brick wall 2/3, will not bring too much burden on the structure of the house itself, noise effects can be, because the hollow brick inside Hole in the arrangements on the noise function to consider, relatively speaking, 95 brick wall thickness and hollow brick is the same, heavy weight, sound insulation effect than the hollow brick to slightly better. But I suggest that the main building brick wall, then the best use of steam concrete blocks, to achieve the best results!

- Q:Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- First with glue all roller brush again, and then approved once again talcum putty (as in the north with a double powder, that is, "white"), sand polish after leveling, you can roll the new latex paint. There is a need for a patch on the wall, just at the same time.

- Q:Is it good for brick walls or light walls?

- If you do not have any requirements for noise, you can use light steel keel gypsum board wall, but can not hang things Oh, can not touch, easy to bad. And it's not fire at all. Home in the living room to do a small partition can also be, but used as a large room partition is not desirable

- Q:In Shanghai 75 partition wall light steel keel 0.6 what price now

- The general keel material costs 34 or so manual 15 that you look at the offer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stud Chinese Drywall C Channel Metal Stud Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords