Structural Steel H-Beam;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

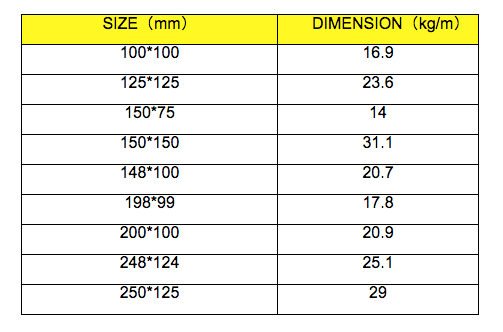

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:Can steel H-beams be used in curved or sloped structures?

- Steel H-beams are indeed suitable for use in curved or sloped structures. Although they are typically employed in straight structures to handle substantial loads, they can also accommodate curved or sloped structures with appropriate design considerations. To achieve the desired shape, the beams can be bent or curved, showcasing their adaptability for diverse architectural designs. Nevertheless, it is crucial to seek advice from a structural engineer or a steel construction expert to guarantee that the beams are accurately designed, fabricated, and installed, enabling them to endure the forces and stresses linked to the curved or sloped structure.

- Q:What are the common defects found in steel H-beams?

- Steel H-beams may have various defects that can be commonly observed. Surface imperfections, including scratches, pits, or dents, are among the most frequent defects. These imperfections may arise during the manufacturing process or due to mishandling during transportation or storage. Another defect that is commonly found in H-beams is related to welding. Since H-beams are typically created by welding different sections together, improper welding techniques can result in defects like cracks, lack of fusion, or excessive weld spatter. Misalignments are also prevalent defects in steel H-beams. When the flanges or webs of the beam are not aligned properly, it can cause an uneven or twisted shape. Such misalignments can compromise the overall structural integrity of the beam and necessitate corrective actions for ensuring proper functionality. Furthermore, dimensional deviations can be detected in H-beams. These deviations may involve variations in length, width, or height, which can have an impact on the beam's stability and load-bearing capacity. Lastly, corrosion is another defect that may affect steel H-beams, particularly when they are exposed to outdoor or corrosive environments. If the beam lacks proper protection through coatings or if there are gaps in the protective layer, rust formation and deterioration of the steel can occur. In conclusion, it is crucial to inspect H-beams for these common defects to guarantee their quality and structural integrity. Consistent maintenance, appropriate handling, and adherence to manufacturing standards can effectively prevent these defects and ensure the long-lasting performance of the beams.

- Q:Are steel H-beams resistant to impact and vibration?

- Yes, steel H-beams are generally resistant to both impact and vibration due to their strong structural design and material properties. The H-shape provides excellent load-bearing capabilities, allowing the beams to withstand significant impact forces without deformation or failure. Additionally, the inherent stiffness and rigidity of steel make H-beams highly resistant to vibrations, ensuring their stability and durability in various applications.

- Q:What are the common connection methods for steel H-beams?

- The common connection methods for steel H-beams include welding, bolting, and using mechanical connections such as clips or brackets. Welding is the most common method and involves fusing the beams together using heat and filler material to create a strong, permanent connection. Bolting is another popular method, where steel plates are drilled and bolted onto the flanges of the H-beams to hold them together. This method allows for easier disassembly or modification if needed. Mechanical connections, such as clips or brackets, are often used for temporary or adjustable connections and provide a quick and easy way to connect H-beams without the need for welding or drilling. These connections are usually used for lighter loads or non-structural applications. Ultimately, the choice of connection method depends on the specific requirements of the project, such as load capacity, ease of installation, and the need for future modifications.

- Q:What are the different types of connections used for steel H-beams to timber?

- To join steel H-beams and timber, there are several types of connections available. These connections are commonly employed in construction projects that involve the integration of steel and timber components. 1. Bolting: Connecting steel H-beams to timber can be achieved through the widely used method of bolting. This method entails drilling holes in both the steel beam and timber and fastening them together using bolts. This connection method ensures a robust and rigid joint. 2. Welding: Another approach to connect steel H-beams and timber is by welding. This technique involves melting the surfaces of the steel beam and timber together, allowing them to cool and solidify. Welding creates a connection of high strength, but it necessitates specialized equipment and expertise. 3. Steel plates: Steel plates can be utilized as a means to connect steel H-beams and timber. This method involves attaching steel plates to the ends of the beams and then connecting them to the timber using bolts or other fasteners. The utilization of steel plates ensures a durable and dependable connection. 4. Timber connectors: Specific timber connectors are available for connecting steel H-beams and timber. These connectors are specially designed to establish a secure and stable joint between the two materials. Examples of timber connectors include angle brackets, gusset plates, and timber connectors with pre-drilled holes for bolts. 5. Adhesive bonding: In certain cases, adhesive bonding can be employed to connect steel H-beams and timber. This technique involves the application of a strong adhesive between the surfaces of the steel beam and timber, allowing it to cure. Adhesive bonding can establish a strong and long-lasting connection, although its suitability may vary depending on the specific application. It is crucial to consider various factors, such as structural requirements, load-bearing capacity, and project design, when selecting a connection method. Consulting with a structural engineer or a professional in the field is essential to determine the most suitable connection method for steel H-beams and timber in a given construction project.

- Q:Can steel H-beams be used in data center construction?

- Yes, steel H-beams can be used in data center construction. Steel H-beams are commonly used in construction projects due to their strength, durability, and versatility. They provide excellent load-bearing capabilities, making them suitable for supporting heavy equipment and structures in data centers. Additionally, steel H-beams offer a high degree of flexibility in design and can be easily customized to meet specific construction requirements. Their use ensures the stability and longevity of the data center, making them a popular choice in the construction industry.

- Q:How do steel H-beams contribute to the overall sustainability of a structure?

- Steel H-beams contribute to the overall sustainability of a structure in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions, seismic activities, and fire, which ensures the longevity and safety of the structure. This durability reduces the need for frequent repairs or replacements, minimizing the consumption of resources and waste generation. Additionally, steel H-beams are lightweight compared to other building materials like concrete or wood, which reduces the overall weight of the structure. This lightweight characteristic allows for more efficient transportation and construction processes, leading to reduced energy consumption and carbon emissions during construction. Moreover, steel H-beams are highly recyclable, making them a sustainable choice. At the end of a building's life cycle, these beams can be easily dismantled and recycled into new steel products without losing their inherent properties. Recycling steel reduces the demand for virgin materials, conserves energy, and reduces greenhouse gas emissions associated with the production of new steel. Furthermore, steel H-beams offer design flexibility, allowing architects and engineers to create innovative and efficient structures. Their versatility enables the optimization of material usage, reducing waste and maximizing the use of resources. This adaptability also facilitates the future adaptability of the structure, allowing for modifications or expansions without extensive demolition or reconstruction. Lastly, steel H-beams have a high strength-to-weight ratio, meaning they can support larger loads with less material. This efficiency in material usage reduces the overall environmental impact of the structure, as less steel is required to achieve the same structural integrity. Therefore, the use of steel H-beams in construction contributes to the conservation of resources and minimizes the carbon footprint of the building. In conclusion, steel H-beams contribute to the overall sustainability of a structure through their durability, lightweight nature, recyclability, design flexibility, and efficient material usage. By choosing steel H-beams, we can create structures that are not only safe and long-lasting but also environmentally friendly, conserving resources and reducing the carbon footprint of the construction industry.

- Q:Are steel H-beams resistant to electromagnetic interference?

- Steel H-beams are generally not resistant to electromagnetic interference (EMI). Steel is a good conductor of electricity, meaning it can easily conduct electromagnetic waves and allow interference to pass through. Electromagnetic interference refers to the disturbance caused by electromagnetic radiation from external sources, such as radio waves, electrical equipment, or other electromagnetic fields. Steel H-beams, commonly used in construction for their strength and load-bearing capabilities, do not have specific properties that make them resistant to EMI. However, it is important to note that the level of interference experienced will depend on various factors, including the thickness of the steel, the presence of other materials or coatings, and the intensity and frequency of the electromagnetic waves. To mitigate electromagnetic interference, various techniques can be employed, such as using shielding materials, applying coatings or insulators, or implementing proper grounding and bonding techniques. These measures can help reduce the impact of EMI on steel H-beams and the structures they are a part of.

- Q:Are steel H-beams customizable or available in standard sizes only?

- Steel H-beams are highly customizable and can be made to fit specific project requirements. However, they are also available in standard sizes for general construction purposes.

- Q:Can steel H-beams be used for agricultural storage buildings?

- Yes, steel H-beams can be used for agricultural storage buildings. Steel H-beams are commonly used in construction due to their strength and durability. They provide excellent structural support and can withstand heavy loads, making them suitable for storing agricultural equipment, machinery, and produce. Additionally, steel buildings are resistant to pests, fire, and adverse weather conditions, making them a reliable choice for agricultural storage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Structural Steel H-Beam;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords