Structural Carbon Steel H Beam High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Guidelines

Structure of product description:

What is the product?

High Quality Structural Carbon Steel H Beam

OKorder is proud to be offering hot rolled High Quality Structural Carbon Steel H Beams. Our Steel Beams meet all GB, JIS, and ASTM ST standards; available in Q235, Q345, SS400, S235JR, S275JR, S355JR grades. We are able to meet all client requirements as well as offer standard sizes of 5.8-12m - all either painted, galvanized or punch holed.

What is the intended use of the product?

The intended use of High Quality Structural Carbon Steel H Beam

Our H Beams are ideal for:

Construction support beams for commercial and residential construction

Mezzanines and platforms

Bridges

Trailer and truck bed framing

Machine bases

What is the product’s advantage?

The advantage of High Quality Structural Carbon Steel H Beam

OKorder is able to quickly ship orders within 20 days of receiving a deposit or original L/C. All products are shipped with ISO, SGS, BV, and CIQ certification as well as additional standards.

Main features of the product

Main features of High Quality Structural Carbon Steel H Beams

- ISO, SGS, BV and CIQ Certified

- Custom Sizes Available

- Shipped within 20 Days

FAQ:

- 3 FAQ’s minimum per product (use of single and phrase keywords in the question and answer of the FAQ’s)

Q1: Why you buy Materials & Equipment from OKorder.com ?

A: All products on OKorder.com are carefully selected from China's quality manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and commitment toward supply chain safety and customer satisfaction.

Q2: What is Carbon Steel ?

A: Modern steels are made with varying combinations of alloy metals to fulfill many purposes. Carbon steel, composed simply of iron and carbon, accounts for 90% of steel production.

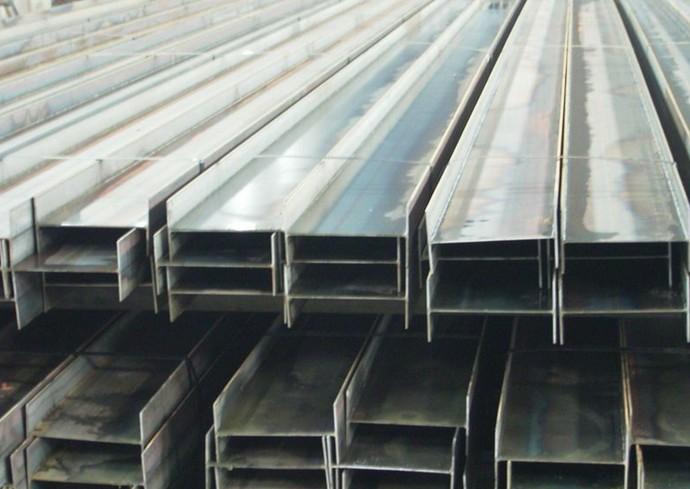

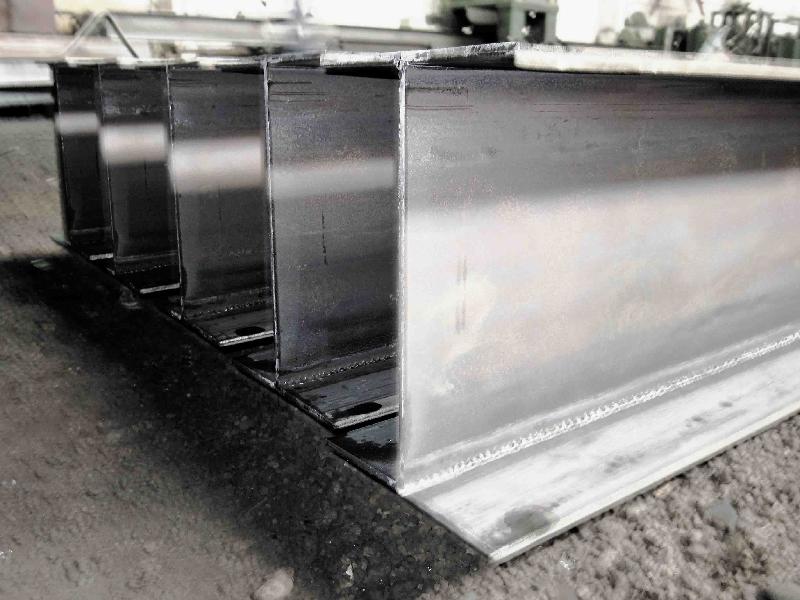

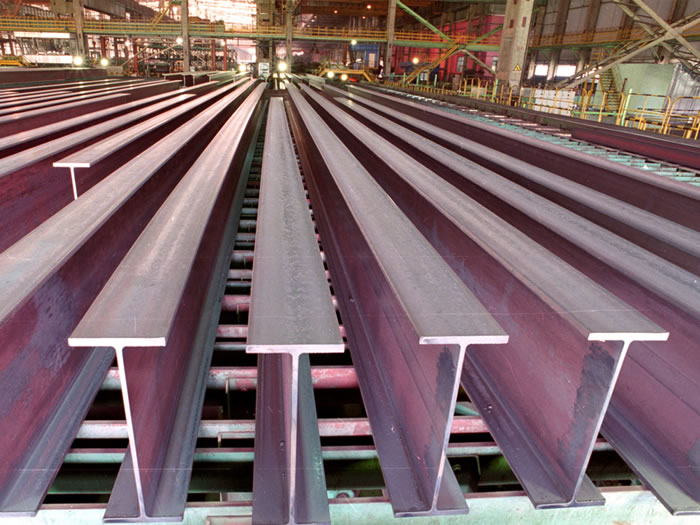

Images:

Specifications:

Specifications of High Quality Structural Carbon Steel H Beam

Place of Origin: | China (Mainland) | Grade: | SS400 | Technique: | Hot Rolled |

Application: | building,construction | Length: | 6-12m | Standard: | JIS |

Flange Width: | 50-300mm | Flange Thickness: | 5-16mm | Web Width: | 100-900MM |

Web Thickness: | 7-28MM | Brand Name: | NBSTEEL | Model Number: | 100*50*5*7-900*30*16*28 |

Standard: GB, JIS, ASTM ST

Material: Q235, Q345, SS400, S235JR, S275JR, S355JR

Length: 5.8-12m or according to our clients' requirements

Origin: Tangshan, China

Package: load on 20 feet/40 feet container or by bulk according to the quantity and our client's requirement

Delivery time: within 20 days after receiving deposit or original L/C

Certificate: ISO, SGS, BV, CIQ or other test

Technic: Hot rolled

Surface: painted, galvanized or punch holes

Main market: East-south Asia, Mid-east, South American

Usage: Construction structure and Frame use

Other Main products: Angle steel, I beam and Channel steel

Images:

- Q:Can steel I-beams be used for industrial manufacturing facilities?

- Yes, steel I-beams are commonly used in industrial manufacturing facilities for their strength, durability, and versatility. Steel I-beams are capable of supporting heavy loads and are often used as structural supports in factories and warehouses. They provide stability and can withstand the demanding conditions typically found in industrial environments, such as high temperatures, heavy machinery, and constant vibrations. Additionally, steel I-beams can be easily fabricated, allowing for efficient customization and assembly in various manufacturing layouts.

- Q:How do steel I-beams handle vibrations from nearby industrial operations?

- Steel I-beams are renowned for their exceptional structural integrity and ability to withstand various types of vibrations. When it comes to vibrations caused by nearby industrial activities, steel I-beams are highly efficient in dampening and dispersing these vibrations. The design of I-beams plays a crucial role in their ability to handle vibrations. The "I" shape provides unparalleled strength and stiffness, enabling the beams to resist bending and undesired deflections resulting from vibrations. The vertical flanges and horizontal web work in tandem to distribute and transfer vibrations throughout the entire length of the beam, minimizing concentrated stress. Moreover, steel I-beams possess inherent damping properties that aid in absorbing and dissipating vibrations. The material's high density and stiffness effectively convert vibrational energy into heat, reducing the amplitude and frequency of vibrations. This damping effect ensures that vibrations do not cause excessive movement or resonance within the structure. Additionally, steel I-beams can be further optimized to handle vibrations by incorporating various techniques. These techniques include the utilization of tuned mass dampers, which are additional masses strategically attached to the beams to counteract specific vibration frequencies. This technique significantly reduces vibration amplitude and minimizes their impact on the structure. Furthermore, steel I-beams can be designed to possess a higher natural frequency, which helps avoid resonance with frequencies generated by nearby industrial operations. By adjusting the size and shape of the I-beam, engineers can ensure that the beam's natural frequency is significantly different from the frequencies produced by nearby operations, preventing resonance and potential damage. Overall, steel I-beams are exceedingly effective in handling vibrations resulting from nearby industrial activities. Their inherent properties, such as exceptional strength, stiffness, and damping capabilities, combined with additional techniques like tuned mass dampers and natural frequency adjustments, make them an ideal choice for structures requiring the ability to withstand and mitigate vibrations.

- Q:Can steel I-beams be used in outdoor applications?

- Yes, steel I-beams can be used in outdoor applications. Steel I-beams are known for their strength and durability, making them suitable for various construction projects, including outdoor applications. They are commonly used in outdoor structures such as bridges, building frames, and support structures. Steel is resistant to weather elements such as rain, wind, and extreme temperatures, making it ideal for outdoor use. Additionally, steel can be treated or coated to provide further protection against corrosion and rust, ensuring its longevity in outdoor environments. Overall, steel I-beams are a reliable and versatile choice for outdoor applications due to their strength, durability, and resistance to weather conditions.

- Q:Can steel I-beams be used for retaining walls or foundation support?

- No, steel I-beams are not typically used for retaining walls or foundation support. These types of structures require specific materials, such as reinforced concrete, that can provide the necessary strength, stability, and durability to withstand the forces exerted by the soil and other external factors.

- Q:How do steel I-beams distribute loads?

- Steel I-beams distribute loads by transferring the weight or force applied to them to the vertical support columns or walls on either end of the beam. The flanges (horizontal top and bottom sections) of the I-beam resist bending, while the web (vertical middle section) resists shear stress. This design allows the I-beam to efficiently distribute and transfer loads along its length, making it a common choice for structural support in buildings and bridges.

- Q:Can steel I-beams be used in temporary structures?

- Yes, steel I-beams can be used in temporary structures. They are commonly used in construction projects where temporary support is required, such as during the construction of bridges, scaffolding, or temporary shelters. The strength and durability of steel I-beams make them suitable for temporary structures that need to withstand heavy loads and provide stability.

- Q:How do steel I-beams perform in seismic regions?

- Steel I-beams are widely known for their strength and durability, making them a popular option for construction in seismic areas. The performance of steel I-beams in seismic regions is generally outstanding, as they possess several qualities that make them suitable for withstanding earthquake forces. To begin with, steel I-beams have a high strength-to-weight ratio, allowing them to support heavy loads without being excessively heavy themselves. This is crucial in seismic regions, where buildings must withstand lateral forces generated during earthquakes. The lightweight nature of steel I-beams enables flexible and efficient structural systems that can better absorb and dissipate seismic energy. Moreover, steel is renowned for its ductility, meaning it can undergo significant deformations without losing its capacity to carry loads. In seismic areas, buildings must absorb and dissipate the energy produced by ground shaking. Steel I-beams possess this ductility, allowing them to bend and yield under seismic forces, effectively dissipating the energy and avoiding catastrophic failures. Additionally, steel I-beams can be designed with excellent connection details, ensuring effective force transfer between beams and columns. This is particularly important in seismic regions, where the connections between structural elements must be strong enough to resist significant lateral forces during earthquakes. Furthermore, steel exhibits predictable and consistent material behavior, enabling accurate analysis and design of structures in seismic areas. Engineers can employ advanced computer modeling and simulation techniques to evaluate the performance of steel I-beams under seismic loads, ensuring their ability to withstand and safely dissipate the forces generated during earthquakes. In conclusion, steel I-beams perform exceptionally well in seismic areas due to their high strength-to-weight ratio, ductility, excellent connection details, and predictable material behavior. These qualities make steel I-beams a reliable choice for constructing earthquake-resistant buildings. However, it is important to note that proper design, detailing, and construction techniques are crucial to ensure optimal performance of steel I-beams in seismic regions.

- Q:How do steel I-beams handle vibrations and dynamic loads?

- The inherent structural characteristics of steel I-beams make them effective in handling vibrations and dynamic loads. This is attributed to the shape of an I-beam, which consists of flanges and a web that provide a high level of stiffness and strength. As a result, I-beams are capable of withstanding dynamic loads and vibrations without deforming or failing. One of the key factors that enables I-beams to handle vibrations is their high moment of inertia. The shape of an I-beam distributes the material away from the neutral axis, increasing resistance to bending. This stiffness prevents deformation or failure when subjected to vibrations or dynamic loads. Furthermore, the flanges of the I-beam reinforce its overall strength. Acting like a protective layer, the flanges help distribute the loads evenly along the beam, reducing stress concentration points. This characteristic effectively absorbs and disperses the energy generated by vibrations or dynamic loads, preventing localized failures. Steel, as a material, also plays a significant role in the I-beam's ability to handle vibrations and dynamic loads. Its high strength-to-weight ratio allows for the creation of lightweight yet strong structures. The durability and resilience of steel make I-beams suitable for withstanding repetitive loads and vibrations without significant deformation or fatigue. Additionally, the design and fabrication of I-beams take into account the anticipated loads and vibrations that the structure will experience throughout its lifetime. Engineers carefully consider factors such as the expected frequency, amplitude, and duration of the vibrations, as well as any potential resonance effects. This allows for the optimization of the I-beam's design to effectively handle specific vibrations and dynamic loads. In conclusion, steel I-beams are well-equipped to handle vibrations and dynamic loads due to their high moment of inertia, the reinforcement provided by their flanges, and the inherent strength and resilience of steel as a material. Through meticulous design and engineering, these beams can effectively absorb and distribute the energy generated by vibrations, ensuring the stability and longevity of the structure they support.

- Q:Are there any insulation requirements for steel I-beams?

- Steel I-beams must be insulated due to their high conductivity, which allows for the easy transfer of heat and cold. Insulating them is crucial in building construction to prevent heat loss or gain and improve energy efficiency. The insulation requirements for steel I-beams may differ based on factors such as building type, location, and local building codes. However, there are general guidelines and standards that can be followed. One common approach to insulating steel I-beams involves using materials like mineral wool, spray foam, or rigid foam board. These materials are typically applied around the beams to create a thermal barrier, preventing heat or cold transfer. The thickness and type of insulation needed depend on factors like the desired R-value (a measure of insulation effectiveness) and specific building requirements. It is recommended to consult local building codes and professionals like architects or engineers to determine the appropriate insulation requirements for steel I-beams in a particular project. Insulating steel I-beams not only helps regulate temperature and improve comfort within a building but also reduces energy consumption. Additionally, it can contribute to achieving sustainable building certifications like LEED (Leadership in Energy and Environmental Design). To summarize, insulation requirements for steel I-beams are necessary for energy efficiency and thermal comfort in buildings. By following local building codes and seeking professional advice, the appropriate insulation materials and techniques for steel I-beams in a construction project can be determined.

- Q:Can steel I-beams be used for renewable energy projects?

- Yes, steel I-beams can be used for renewable energy projects. These beams are commonly used in the construction of various renewable energy structures such as wind turbines, solar panel installations, and hydroelectric power plants. They provide structural support and stability to these projects, ensuring their longevity and efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Structural Carbon Steel H Beam High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords