Stretch Film Masking Protective Cast For Auto Paint

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

- Option:

- Stretch Film

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stretch Film Masking Protective Cast For Auto Paint

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. Pretaped with Masking Tape, which is sunlight stable and gives the user 7-day clean removal. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Sunlight stable even on glass

Indoor/outdoor painting

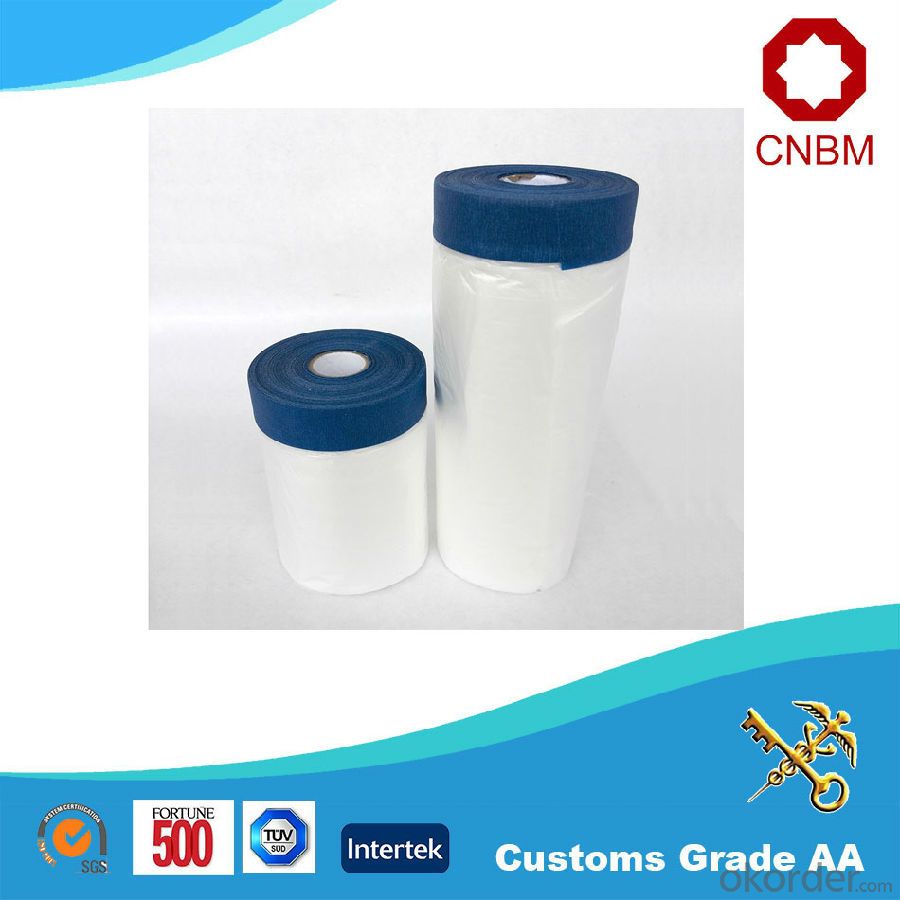

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. Packing and shipping

It is wraped by hot shrink POF film with adhesive lable. 50 rolls or 25rolls packing in to one carton.

After receiving the deposite, it will take around 20 days before shippment.

Q1. What is the main sizes of masking film?

4mx2.5m,4mx5m, 4mx6m, 4mx8m, 4mx10m, 4mx12.5m, 2mx25m, 2mx50m

6ftx12ft, 8ftx12ft, 9ftx12ft, 10ftx20ft, 9x400ft

Q3. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

- Q:What are the different types of packaging tape?

- There are several different types of packaging tape available for various packaging needs. 1. Clear Packaging Tape: This is the most common type of packaging tape, typically made from polypropylene or acrylic materials. It is transparent, allowing for easy visibility of labels or printed information on the package. Clear packaging tape is versatile and suitable for most general packaging applications. 2. Brown Packaging Tape: Also known as brown packing tape or brown carton sealing tape, this type of tape is made from strong, durable materials such as polypropylene or paper. It is commonly used for sealing cardboard boxes or packages, providing a secure and tamper-evident seal. Brown packaging tape is ideal for shipping and general packaging purposes. 3. Masking Tape: While not specifically designed for packaging, masking tape can be used for light-duty packaging tasks. It is made from a thin and easily tearable paper and is commonly used for holding, bundling, or labeling packages. However, masking tape may not provide the same level of strength and security as dedicated packaging tapes. 4. Duct Tape: Similar to masking tape, duct tape is not primarily designed for packaging purposes but can be used in certain situations. It is a strong and durable tape, typically made from cloth or reinforced with fibers, and is known for its adhesive strength and versatility. Duct tape can be used for heavy-duty packaging tasks or for securing packages in challenging environments. 5. Specialty Packaging Tapes: There are various specialty packaging tapes available to cater to specific needs. Some examples include fragile tape, which has a warning message to indicate delicate items inside the package, or double-sided tape, which allows for secure attachment of items or joining of materials. Additionally, there are tapes designed for specific industries, such as freezer tape for sealing packages in cold storage or electrical tape for insulating electrical wires during packaging. Overall, the choice of packaging tape depends on the specific requirements of the packaging task, including the type of materials being sealed, the desired level of security, and any specific conditions or considerations.

- Q:Does packaging tape come in different widths for sealing different-sized items?

- Yes, packaging tape is available in different widths to accommodate sealing different-sized items.

- Q:How does packaging tape perform on recycled or eco-friendly packaging materials?

- Packaging tape generally performs well on recycled or eco-friendly packaging materials. Most packaging tapes are designed to adhere to a variety of surfaces, including paper-based or biodegradable materials commonly used in eco-friendly packaging. However, it is always recommended to check the compatibility of the specific tape with the packaging material to ensure optimal adhesion and sustainability.

- Q:Does packaging tape have any specific certifications or standards?

- Packaging tape possesses specific certifications and standards. Various organizations and standards establish guidelines for packaging materials, including packaging tape. One of the most prevalent certifications for packaging tape is the ISO certification from the International Organization for Standardization. ISO establishes quality management system standards, and packaging tape can acquire certification under ISO 9001:2015 to ensure that it meets specific quality criteria. Apart from ISO certification, packaging tape can also conform to industry-specific standards like those set by ASTM International or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards guarantee that the tape satisfies particular requirements concerning strength, adhesion, and durability. Furthermore, certain packaging tapes may possess certifications associated with their environmental impact. For instance, specific tapes may be certified as recyclable, biodegradable, or made from sustainable materials. Organizations like the FSC or the SFI grant these certifications to promote responsible forestry practices. It is crucial to note that not all packaging tapes will possess certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it indicates that the product satisfies particular quality, performance, or environmental criteria.

- Q:Does packaging tape come with a dispenser?

- Packaging tape often comes accompanied by a dispenser, aiming to facilitate and optimize the application of the tape onto packages. The dispenser is usually equipped with a handle, granting you the ability to firmly grasp and manage the tape while sealing boxes or packages. This eliminates the necessity of manually cutting the tape, as well as prevents any entanglement or wastage. However, it is crucial to acknowledge that not all packaging tapes are bundled with a dispenser. Some tapes may require separate purchase, whereas others may be conveniently offered as a set, inclusive of the dispenser. It is always advisable to consult the product description or packaging for confirmation regarding the inclusion of a dispenser alongside the packaging tape.

- Q:How do I prevent packaging tape from tearing during removal?

- To prevent packaging tape from tearing during removal, there are a few strategies you can try: 1. Apply heat: One effective method is to use a hairdryer or heat gun to warm up the tape. The heat softens the adhesive, making it easier to peel off without tearing. Be careful not to overheat or burn the tape, though. 2. Use a cutting tool: If the tape is difficult to remove, you can use a sharp cutting tool like a utility knife or scissors to carefully cut through it. This way, you can avoid tearing the tape and remove it in smaller, more manageable sections. 3. Slow and steady approach: Take your time and be patient when removing the tape. Pull it slowly and at a low angle, applying gentle pressure to avoid tearing. If you encounter resistance, stop and try a different angle or apply a bit of heat to loosen the adhesive. 4. Seek assistance from a solvent: If the tape is particularly stubborn, you can try using a solvent like rubbing alcohol or adhesive remover. Apply a small amount to a cloth or cotton ball and gently rub it on the tape to dissolve the adhesive. Test the solvent on a small, inconspicuous area first to ensure it doesn't damage the surface. 5. Choose the right tape: Using high-quality packaging tape can also help prevent tearing during removal. Look for tapes with strong adhesion and good tensile strength. Reinforced or heavy-duty tapes tend to be more resistant to tearing. By employing these techniques and being cautious, you can successfully remove packaging tape without tearing it.

- Q:Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q:Can packaging tape be used for sealing wooden crates?

- Sealing wooden crates can indeed be accomplished with packaging tape, which creates a sturdy and reliable bond. This ensures that the crate remains tightly sealed throughout transportation or storage. Packaging tape is specifically designed to adhere well to different surfaces, including wood, making it an excellent option for sealing wooden crates. Nevertheless, it's crucial to take into account the weight and dimensions of the crate before solely depending on packaging tape. In the case of heavier or larger crates, reinforcing the seal with supplementary methods like nails or screws may be necessary.

- Q:Can packaging tape be used for sealing plastic tubing?

- Packaging tape has the capability to seal plastic tubing. Its design ensures a robust and reliable seal on different surfaces, including plastic materials. Nonetheless, it is crucial to take into account the particular purpose and demands of the plastic tubing. In instances where the tubing is intended for containing pressurized liquids or gases, or if it necessitates a long-lasting and resilient seal, specialized techniques like heat sealing or specific adhesives formulated for plastic materials might be more suitable. Ultimately, the appropriateness of packaging tape for sealing plastic tubing relies on the specific situation and requirements of the application.

- Q:Can packaging tape be used for sealing automotive or vehicle parts?

- Yes, packaging tape can be used for sealing automotive or vehicle parts to some extent. However, it is not the most suitable or long-lasting solution for this purpose. Packaging tape is primarily designed for sealing cardboard boxes and other packaging materials, so its adhesive properties may not be strong enough to withstand the rigors of automotive applications. Additionally, automotive parts are often exposed to high temperatures, vibrations, and various chemicals, which can cause the packaging tape to degrade or lose its adhesion over time. Therefore, it is generally recommended to use specialized automotive sealants or adhesives that are specifically designed for sealing vehicle parts to ensure durability and optimal performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stretch Film Masking Protective Cast For Auto Paint

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

- Option:

- Stretch Film

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords