Stone Coated Roofing Sheet with New Design from CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

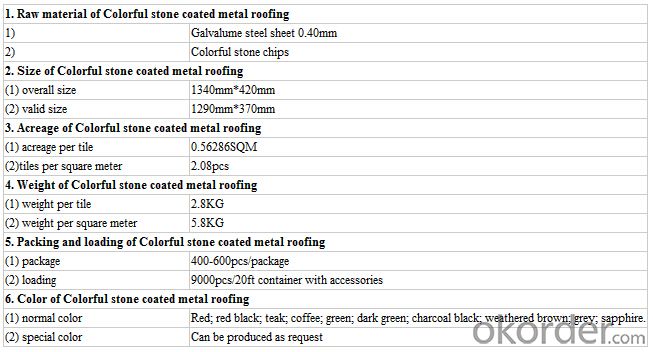

Product Introduction:

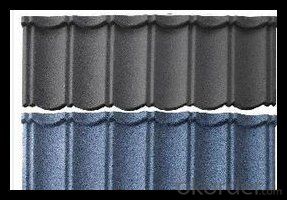

Color Stone Coated metal Roof is based on Al-Zn(Known as Zincalume or Galvalume steel)steel. The before and after protective film treatment, together With high precision pressure-shaped gravel ensure the roof to be the best roofing material. Coated With an alloy composed of Al 55%, Zn 43.4%,Si 1.6%, with Non-toxic acrylic adhesive and natural stone, Color Stone Coated metal Roof provides the advantages of long life, strength, durability and beauty.

Product Advantages:

1. Light weight.

To compare with the traditional ceramic tile, the weight of our metal roof tile is just 1/6 of it.

It is convenient to carry, store and use, so it can save the time and cost of installation.

2. Easy installation.

Metal roof tile is very light and it is easy to incise and cut off, so it is suitable for all kinds of buildings,

especially for the heavy grade roofs and towers.

3. Excellent durability.

High quality galvalume plates and natural stone chip coatings are characterized by their excellent

anti corrosion features which extends the life span of tiles for more than 30 years without fade.

4. Recyclable and Eco-friendly.

Metal roof tiles are galvalume based and have high recyclable content. Over 90% of the tiles are

recyclable,which makes it more economical.

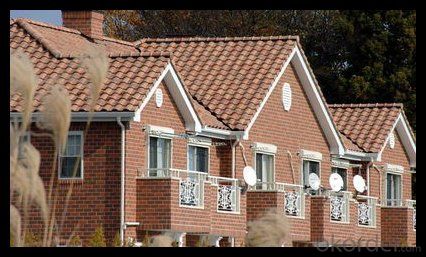

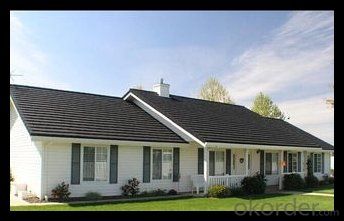

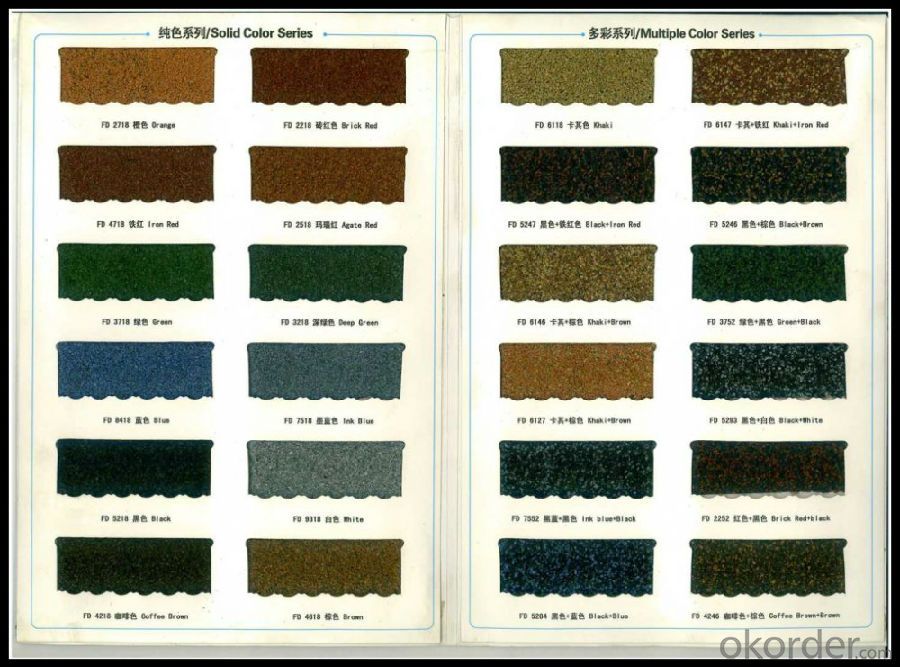

5. Beautiful appearance.

Rich color and variety types will bring a beautiful surface for your roof.

6. Earthquake resistance.

Earthquake can cause the infinite property loss, the more is because of the structure roof and the

weight of tile. Stone coated metal roof tiles are light and firm,they can lighten the building and won’t

easily cause damages to the under structures of the buildings in earthquakes.

7. Wind resistance.

Even metal tile just has the 1/6 of weight to the traditional tile,the scientific interlocking system design

techniques guarantee the roofing system more safety in the storms.

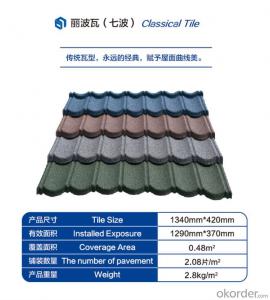

Product Specification:

FAQ:

Q: What's your payment?

A: T/T, L/C, etc.

Q: Can you offer samples?

A: Yes, we could offer according to customer's requirement.

Q: Can I check the quality before loading?

A: Yes, it will be better.

- Q:The ceiling is the singing of the aluminum plate with vibrating sound how to do it

- First to improve the installation, requiring workers to rectification of the aluminum slab plate, the installation gap to be small, can not be loose.

- Q:What is the material of the polymer film of aluminum-plastic plate?

- Usually we often say that the polymer membrane is an indispensable process for the production of aluminum-plastic composite panels.

- Q:How to adjust the length of the aluminum plate

- The width of the custom is often in order to avoid excessive loss, a variety of raw materials need to be wide or narrow that kind, so there will be some cost in the procurement, a small increase in the price of course.

- Q:Aluminum veneer, aluminum-plastic plate and aluminum honeycomb curtain wall material is different

- Aluminum veneer is a layer of pure aluminum, aluminum-plastic plate is two layers of pure aluminum plate with pvc, honeycomb aluminum plate is between the two layers of aluminum plate with honeycomb, which is the most expensive honeycomb board, followed by Aluminum veneer, and finally aluminum-plastic panels, but the need for their own processing of aluminum-plastic panels, waste, short life, according to different processing, the price will be high. Effect and quality of the best is the honeycomb board (surface smooth, strong wind pressure), very on the grade, the use of the world less, the reason is the price is too high. Life and aluminum veneer is basically the same,

- Q:China, there is no sale of Japan is not the Department of aluminum or steel pipe

- The composition of aluminum-plastic composite plate is made of multi-layer composite material, the upper and lower layers of high-purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, the front also paste a protective film. For outdoor, aluminum-plastic panels coated with fluorocarbon resin (PVDF) coating, for the interior, the front can be non-fluorocarbon resin coating. Features of aluminum-plastic plate Aluminum-plastic plate is easy to process, forming a good material. But also for the pursuit of efficiency, for the time of the fine products, it can shorten the duration and reduce costs. Aluminum-plastic plate can be cut, cut, slotted, band saw, drilling, processing buried head, you can also cold bending, cold fold, cold rolling, can also riveting, screw connection or glue bonding.

- Q:About the introduction

- Aluminum-plastic composite panel referred to as aluminum-plastic plate, is made by the surface treatment and coated with aluminum paint as the surface, polyethylene plastic plate as the core layer, after a series of process processing complex made of new materials. The aluminum-plastic panels were first developed by the German company Aiusingen and later improved by Forken and Aloca. 90 years later, the product quality gradually stable, reached a high level. As the aluminum-plastic plate is composed of two different materials (metal and non-metallic), it retains the original composition of materials (metal aluminum, non-metallic polyethylene plastic) the main features, but also to overcome the lack of raw materials , And then get a lot of excellent material properties. Such as luxurious and beautiful, colorful decorative; weathering, corrosion resistance, impact resistance, fire, moisture, heat insulation, sound insulation, light resistance; light, easy processing, easy handling, quick construction and other characteristics. These properties for the aluminum-plastic plate opened up a broad application prospects. Aluminum-plastic panels Due to the many advantages of material properties, it is widely used in a variety of architectural decoration, such as ceilings, pillars, counters, furniture, telephone booths, elevators, stores, billboards, And so on, has become the representative of the three curtain walls (natural stone, glass curtain wall, metal curtain wall) metal curtain wall, in developed countries, aluminum-plastic panels are also used in the bus, the manufacture of train boxes, aircraft, Equipment, equipment, such as the outer box.

- Q:That detailed point Oh, I want the detailed process, which know ah, tell me ah, thank you!

- Super weatherability Due to the use of KYNAR-500-based PVDF fluorocarbon paint, weatherability has a unique advantage, both in the hot sun or cold snow are not detrimental to its beautiful appearance, Up to 20 years does not fade.

- Q:Haida deep brown aluminum-plastic plate

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q:9 meters high aluminum plastic door door fee is how much, Xuzhou area

- Xuzhou area of the labor costs should not be cheap. This highly operational estimates also need 80-120 yuan / square meter it.

- Q:Bedroom room tide, often out of the wall, just finished a year began to fall out, and then also out of the decoration, wallpaper stickers also up, the basic wall can not get anything, want to use the plate to the wet wall separated, Can I use aluminum or aluminum gusset? Or other plates? Which is more suitable for the bedroom, and is a large area

- You can use aluminum-plastic panels, but if you want to look better than the space, aluminum-plastic plate inside to play keel to do, the effect is good, rich color cut easily shape, you want to brush the paint inside the wall to shovel and then brush strong.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stone Coated Roofing Sheet with New Design from CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords