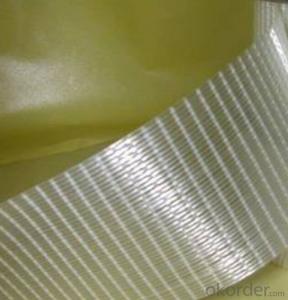

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

FOB Price of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible US $0.22/ Square Meter

MOQ of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible: 10000 Square Meters

Supply Ability of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible: 6000000 Square Meters per Month

Payment Terms of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible: L/C,T/T

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Specifications of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Place of Origin: China (Mainland)

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Brand Name: CMAX

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Application: Wall Materials

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Width: 1M-2M

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Size: 5*5/ INCH

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Weight: 40gsm to 200gsm

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Weave Type: Plain Woven

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Yarn Type: C-Glass

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Alkali Content: Medium

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Standing Temperature: 500℃

Product information of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Name: Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Use best fiberglass yarn and best glue

Clear and beautiful Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

High strength Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

30 years experience of manufacturing Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Excellent Priced Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

FAQ of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Q: What is Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Coated Alkali-resistant Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Weight: 65g Width: 0.2M--2M

Length: 20m, 50m, 100m

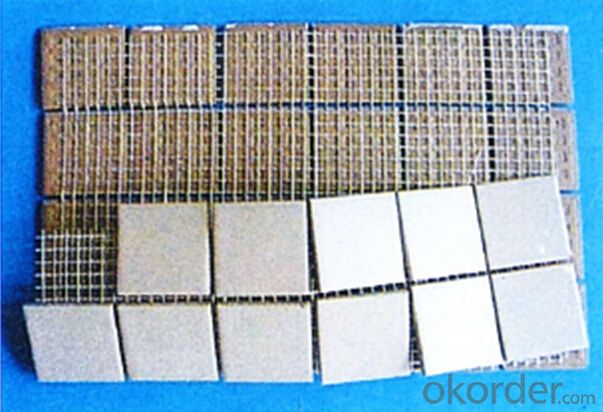

Q: What is the application of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Four years under normal weather conditions and use .

Q: What is the package of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Production periods: 30days for 1X40HQ.

- Q:What are the specifications of fiberglass mesh?

- Fiberglass mesh uses glass fiber woven fabric as the substrate, and is immersed and coated by polymer emulsion resistance. Thus having good alkali resistance, flexibility and high warp-wise and weft tensile strength, it can be widely used in building internal and external wall insulation, waterproof, cracking and so on. Fiberglass mesh is mainly based on alkali-resistant fiberglass mesh, it uses the C or E-glass fiber yarn (main component is silicate which has good chemical stability) , twisted by special organizational structure-- leno weave, and then experiences high temperature heat processed through anti-alkaline, and enhancers. General specifications: 1, Size of mesh: 8mm×8mm,10mm×10mm,12mm×12mm. Width: 60 cm, 90 cm, or 1 meter. 3, Gram?weight per square meter: 125g. 4, Length of each roll: 100m or 50m. 5, Color: White (standard), blue, green or other colors. 6 Package: according to customer's requirements. 7 special specifications and softness can be satisfied according to customer's requirements and reservations.

- Q:What is the advantage of fiberglass mesh in construction?

- Maybe its probablity of surface shedding is smaller than metal mesh, and it is non-conducting and tough, thus avoiding hidden danger.

- Q:Does wall treatment need mesh?

- It depends on the specific quality of the original wall base. If there is no cracks or empty drum, it is usually unnecessary.

- Q:external wall thermal insulation is using 10BJ2-11, external wall F2-1M-3. How to calculate the amount of alkali-resistant glass?fiber mesh.

- Mesh only laying the internal and external corners is ok.

- Q:Is glass fiber harmful to people?

- The extent of skin damage depends on fiber diameter and surface roughness. It is now accepted that fiber diameter exceeds 5 mu m, which has a significant stimulating effect. A small number of people exposed to glass fiber and rock wool have skin allergies, but so far they have not been proved to be allergens. Eye and mucous membrane endanger: the worker that contacts glass fiber and so on can suffer conjunctivitis and keratitis, serious person can see the cornea is cloudy and local abscess. From the patient's eyes, a fiber less than 3 m in diameter can be developed. Pathological examination of the eyeball showed that the proliferation of corneal epithelial cells and the increase of mucin content in the conjunctiva showed mechanical stimulation. Similar pathological changes were confirmed by animal experiments. Experiments show that asbestos substitutes can produce toxicity and carcinogenicity similar to that of asbestos when the size and length of fibers are similar. Asbestos Substitutes dust has the effect of certain biological damage to human and animal, its biological activity and pathological effect is not asbestos, but as the mass production and use of Asbestos Substitutes, the harm can not be ignored.

- Q:Hydraulic oil filter, glass fiber or imported paper is good?

- The HEPA screen made of glass fiber is generally accepted to achieve high efficiency. Because of the high requirement of glass fiber in making technology, the quality of products is low.

- Q:How to distinguish warp?and?weft of alkali-resistant fiberglass mesh?

- The two strands of small wire is warp, and the thicker one is weft. While being used, take warp as a horizontal position.

- Q:What are the bonding requirements of alkali resistant fiberglass mesh? Anti cracking protection layer construction, alkali resistant fiberglass mesh cloth why not dry lap?

- The bonding width of alkali resistant fiberglass mesh shall not be less than 50mm, and the edge of alkali resistant fiberglass mesh cloth shall not be dry lapped, and must be embedded in anti cracking mortar.

- Q:When external wall thermal insulation Mesh use fiberglass mesh not less than 290 g /m 2 , is it avaliable to stick tile? Is there no specific technical specifications or procedures to support?

- As far as I know, heat retaining exterior wall tile must hang galvanized welded wire mesh to strengthen, you can refer to jgj144-2004, many provinces follow this operation, I did not see specification supports tiling with Mesh.

- Q:What's crack resistant mortar composite alkali resistant glass fiber gridding cloth?

- Gridding cloth is a kind of material used for thermal insulation featured by crack resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords