Steel Wire Rods Hot Rolled High Carbon First Class Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

Wire rod steel is widely used for commercial building structure, pre-engineering buildings, machinery support structures, prefabricated structure, medium scale bridges and so on. We have supplied this product for many years and gained widespread reputation.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

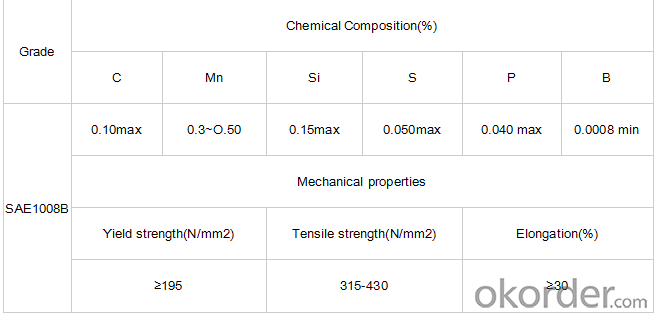

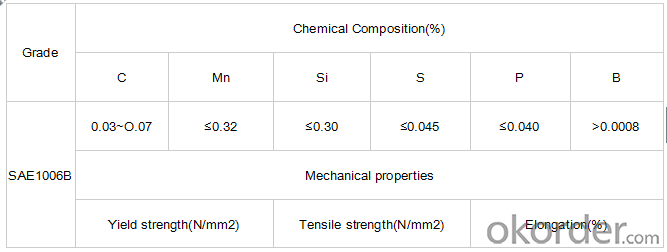

4.Wire Rod Steel for Construction Specification

5.FAQ of Wire Rod Steel for Construction

We have organized several common questions for our clients,may help you sincerely:

1.What is your minimum order quantity ?

Our MOQ is 500mt for each size. And we will consider to give more discount if you make big order like 10000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q:What are the different types of steel wire rod finishes?

- There are several different types of steel wire rod finishes, each designed to provide specific properties and functionalities. Some of the most common types include: 1. Black finish: This is a basic, untreated finish that leaves the steel wire rod with a dark, black color. It provides minimal protection against corrosion, but is commonly used in non-structural applications where aesthetics are not a concern. 2. Galvanized finish: This finish involves coating the steel wire rod with a layer of zinc to protect against corrosion. The zinc coating provides excellent resistance to rust and is commonly used in outdoor applications or in environments where the wire rod may be exposed to moisture. 3. Coated finish: Steel wire rods can also be coated with various materials, such as PVC or nylon, to provide additional protection against corrosion and abrasion. These coatings can also offer improved electrical insulation properties or better grip for specific applications. 4. Stainless steel finish: Stainless steel wire rods are made from an alloy that contains a high percentage of chromium, which provides excellent resistance to corrosion. This finish is commonly used in applications where hygiene, durability, and corrosion resistance are important, such as in the food industry or medical field. 5. Bright finish: This finish involves a mechanical or chemical process that removes any surface impurities or oxidation, leaving the steel wire rod with a smooth, shiny appearance. Bright finishes are often used in decorative applications or where an aesthetically pleasing appearance is desired. 6. Phosphated finish: Phosphating is a chemical process that creates a layer of phosphate coating on the steel wire rod's surface. This finish enhances the wire rod's corrosion resistance and improves its paint adhesion, making it suitable for applications where painting or further coating is required. These are just a few examples of the different types of steel wire rod finishes available. The choice of finish depends on the specific application requirements, such as corrosion resistance, aesthetics, or functional properties needed.

- Q:What are the different types of wire drawing processes used for steel wire rod?

- There are several types of wire drawing processes used for steel wire rod, including single block, multi-block, and continuous wire drawing. In the single block wire drawing process, the wire rod is passed through a single die to reduce its diameter. In the multi-block wire drawing process, multiple dies are used in sequence to further reduce the wire diameter. Continuous wire drawing involves passing the wire rod through a series of dies in a continuous manner to achieve the desired diameter. Each of these processes offers different benefits and is used based on the specific requirements of the steel wire rod.

- Q:How is steel wire rod used in the manufacturing of wire forms for automotive components?

- Steel wire rod is used in the manufacturing of wire forms for automotive components as it serves as the primary material for creating the structural framework of these forms. The steel wire rod is processed through various techniques such as cutting, bending, and shaping to create specific wire forms required for automotive components like springs, brackets, clips, and fasteners. Its high tensile strength and durability ensure that these wire forms can withstand the rigorous demands of automotive applications, providing stability, support, and functionality to the components they are integrated into.

- Q:What are the common applications of alloy steel wire rod?

- Alloy steel wire rod has a wide range of applications due to its unique properties and characteristics. Some of the common applications of alloy steel wire rod include: 1. Automotive industry: Alloy steel wire rods are extensively used in the automotive industry for the production of various components such as springs, suspension systems, wheel rims, and engine parts. The high strength and durability of alloy steel wire rod make it suitable for withstanding the demanding conditions and loads experienced by these components. 2. Construction industry: Alloy steel wire rods are also widely used in the construction industry. They are utilized in the manufacturing of reinforcing bars (rebars) which are essential for reinforcing concrete structures such as bridges, buildings, and highways. The high tensile strength and corrosion resistance of alloy steel wire rod ensure the longevity and structural integrity of these constructions. 3. Manufacturing industry: Alloy steel wire rods find applications in various manufacturing processes such as welding, machining, and fabrication. They are commonly used in the production of fasteners, wire mesh, wire ropes, and springs. The unique properties of alloy steel, such as high tensile strength, good formability, and resistance to wear and fatigue, make it an ideal choice for these applications. 4. Aerospace industry: Alloy steel wire rods are employed in the aerospace industry for the production of components and parts that require high strength, excellent fatigue resistance, and resistance to extreme temperatures. These include aircraft landing gear, engine components, and structural parts. The superior mechanical properties of alloy steel wire rod make it suitable for withstanding the demanding conditions encountered in aerospace applications. 5. Energy industry: Alloy steel wire rods are used in the energy industry for various applications. They are utilized in the manufacturing of power transmission cables, electrical conductors, and wire mesh screens. The high electrical conductivity and corrosion resistance of alloy steel wire rod make it an ideal choice for these energy-related applications. In summary, alloy steel wire rod is commonly used in the automotive, construction, manufacturing, aerospace, and energy industries due to its high strength, durability, formability, and resistance to wear, corrosion, and fatigue. Its versatility and unique properties make it an essential material for a wide range of applications.

- Q:What are the different types of steel wire rod testing equipment after wire drawing?

- There are several types of steel wire rod testing equipment that are used after wire drawing. These include tensile testing machines, which measure the strength and elasticity of the wire; hardness testers, which determine the wire's resistance to indentation or scratching; diameter measuring devices, which ensure the wire's uniformity; and surface inspection systems, which detect any defects or irregularities on the wire's surface. Additionally, there may be specific testing equipment for checking the wire's chemical composition or conducting non-destructive testing.

- Q:How is the quality of steel wire rod measured?

- To assess the mechanical properties, chemical composition, and overall performance of steel wire rod, a series of tests and evaluations are conducted. These evaluations determine the quality of the rod based on several key parameters: 1. Tensile Strength: This test measures the rod's ability to withstand stress before breaking or deforming. It indicates its capacity to bear weight and resist tension. 2. Yield Strength: This test determines the stress level at which permanent deformation occurs. It indicates the rod's ability to return to its original shape after being subjected to stress. 3. Elongation: By measuring the percentage increase in length before the rod breaks under tension, this test provides insights into its ductility and ability to elongate without compromising integrity. 4. Hardness: This test assesses the rod's resistance to indentation or scratching, indicating its strength and durability. 5. Chemical Composition: The steel wire rod's composition is analyzed to ensure it meets the required standards. This involves evaluating levels of carbon, manganese, silicon, sulfur, phosphorus, and other alloying elements. 6. Surface Quality: Visual inspection and sometimes microscopic analysis are conducted to detect defects like cracks, scratches, or impurities. A smooth and clean surface is essential for optimal performance. 7. Dimensional Accuracy: The rod's diameter and length are measured to ensure they adhere to specified tolerances. Deviations from the required dimensions can impact the rod's usability in various applications. 8. Microstructure Analysis: This examination involves detailed observation of the rod's internal structure using microscopy. It helps identify abnormalities such as grain size, inclusions, or segregation that may affect its strength and performance. Through these tests and evaluations, manufacturers can ensure that steel wire rod meets the necessary quality standards and is suitable for its intended applications, such as manufacturing wire products, reinforcing materials, or springs.

- Q:How is steel wire rod tested for quality control?

- Steel wire rod is tested for quality control through various methods. One common method is conducting a chemical analysis to ensure the correct composition of elements such as carbon, manganese, and silicon. Mechanical tests are also performed, including tensile strength and elongation measurements, to evaluate the wire rod's ability to withstand stress. Additionally, surface quality inspections are conducted to check for any defects, such as cracks or surface irregularities. These rigorous testing procedures ensure that steel wire rod meets the required standards and ensures its reliability and durability in various applications.

- Q:What are the factors affecting the price of steel wire rods?

- The price of steel wire rods can be affected by several factors, including: 1. Supply and demand dynamics: The equilibrium between the supply and demand of steel wire rods in the market plays a significant role in determining their prices. When demand surpasses supply, prices tend to rise. Conversely, an excess supply can lead to price reductions. 2. Raw material expenses: The costs associated with raw materials like iron ore and coal, which are essential for manufacturing steel wire rods, can directly impact their prices. Price fluctuations in these inputs can influence the overall production cost and, consequently, the price of steel wire rods. 3. Energy expenditure: The energy-intensive nature of steel production means that variations in energy prices, such as electricity and fuel costs, can have a substantial effect on the price of steel wire rods. Higher energy expenses can increase production costs and result in higher prices for the end product. 4. Currency exchange rates: The international trade of steel wire rods makes them susceptible to currency exchange rate changes. If the currency of a steel-producing country weakens against other currencies, it can enhance their export competitiveness, potentially leading to lower prices in the global market. 5. Government policies and regulations: Government policies, including tariffs, import/export restrictions, and environmental regulations, can impact the price of steel wire rods. Trade barriers can restrict the supply from specific regions, leading to higher prices. Additionally, stricter environmental regulations can raise production costs, which can be passed on to consumers as higher prices. 6. Technological advancements: Advances in technology and production techniques can influence the manufacturing cost of steel wire rods. More efficient production methods can reduce costs and potentially lower prices. However, significant investments in new technologies or higher quality products may result in price increases. In summary, the price of steel wire rods is influenced by market forces, input costs, government policies, and technological advancements. A comprehensive understanding of these factors is crucial for industry participants and consumers to make informed decisions and anticipate price fluctuations in the steel wire rod market.

- Q:How are steel wire rods used in the production of wire hangers?

- Wire hangers rely on steel wire rods as essential components in their production. These rods, serving as the raw material, are transformed into wire hangers through a process involving drawing and processing. The steel wire rods are initially processed and passed through a series of dies to achieve the desired thickness and shape, thereby enhancing the wire's strength and durability. Subsequently, the wire rods are cut into specific lengths to form individual hangers. These hangers are then bent and shaped into their familiar form. The malleability of steel wire rods enables manufacturers to easily manipulate and customize wire hangers, resulting in a variety of styles and sizes to meet diverse needs. By employing steel wire rods, manufacturers ensure the creation of sturdy and dependable hangers capable of effectively supporting garments.

- Q:How is steel wire rod classified based on carbon content?

- Steel wire rod is classified based on its carbon content into three categories: low carbon wire rod, medium carbon wire rod, and high carbon wire rod.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Wire Rods Hot Rolled High Carbon First Class Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords