Steel Structure Warehouse/Workshop GB Standard Material

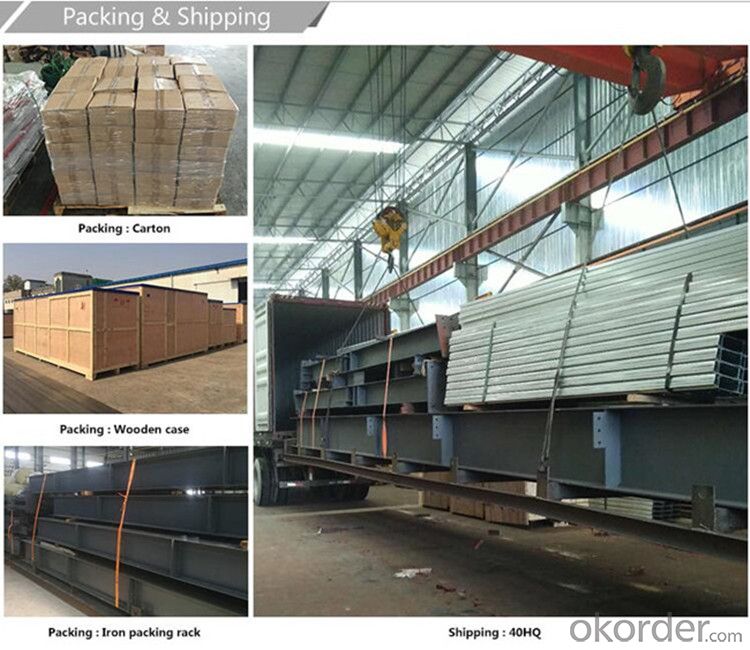

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel Structure Warehouse/Workshop

1. These products are customized products;

2. The following information is required to provide detailed quotation:

A. Project location:

B. Size: Length*width*height _____mm*_____mm*_____mm

C. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

D. Snow load (max. Snow thickness)_____kn/m2, _____mm

E. Anti-earthquake grade_____

F. Brick wall needed or not. If yes, 1.2m high or 1.5m high?

G. Thermal insulation requirement. If yes, EPS/fiberglass wool/rock wool/PU sandwich panels will be suggested; If not, the metal steel sheets will be OK. The cost of the latter will be much lower than the former.

H. Door quantity & size _____units, _____(width)mm*_____(height)mm

I. Window quantity & size _____units, _____(width)mm*_____(height)mm

J. Crane needed or not

Characteristics

1. Enviromental friendly

2. Lower cost and maintenance

3. Long using time up to 50 years

4. Stable and earthquake resistance up to 9 grade

5. Fast construction, time saving and labor saving

6. Good appearance

Use

The steel workshop warehouse building is widely used for workshop plant, warehouse, office building,steel shed, aircraft hangar etc.

Technical Parameters

Items | Specification | |

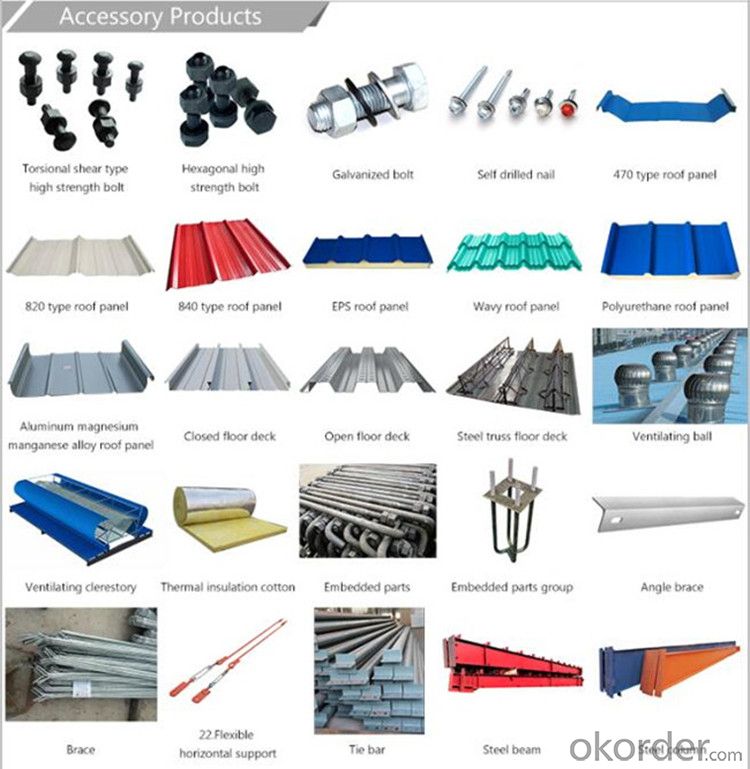

Main Steel Frame | Column | Q235B, Q345B Welded H Section Steel |

Beam | Q235B, Q345B Welded H Section Steel | |

Secondary Frame | Purlin | Q235B C and Z purlin |

Knee brace | Q235B Angle Steel | |

Tie Rod | Q235B Circular Steel Pipe | |

Brace | Q235B Round Bar | |

Vertical and Horizontal Support | Q235B Angle Steel, Round Bar or Steel Pipe | |

Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel /Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet |

Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

Accessories | Window | Aluminium Alloy Window / PVC Window / Sandwich Panel Window |

Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

Rainspout | PVC | |

Live load on Roof | In 120kg/Sq.m (Color steel panel surrounded) | |

Wind Resistance Grade | 12 Grades | |

Earthquake-resistance | 8 Grades | |

Structure Usage | Up to 50 years | |

Finishing Options | Vast array of colors and textures available | |

Paint Options | Zinc rich epoxy painting, one primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized. | |

- Q:How do steel structures contribute to the overall architectural heritage of a building?

- Steel structures contribute to the overall architectural heritage of a building by offering numerous advantages such as strength, durability, and versatility. They allow for the creation of unique and innovative designs, enabling architects to push the boundaries of traditional construction methods. Steel structures also provide the opportunity for large open spaces, allowing for flexible interior layouts and the incorporation of natural light. Furthermore, steel's inherent properties, such as its resistance to fire and its ability to withstand extreme weather conditions, ensure the longevity and safety of the building. Overall, steel structures enhance the architectural heritage of a building by combining functionality, aesthetics, and sustainability.

- Q:How is steel used in transportation infrastructure, such as airports or railway stations?

- Due to its exceptional strength, durability, and versatility, steel finds widespread usage in transportation infrastructure, including airports and railway stations. One of the primary applications of steel in transportation infrastructure involves utilizing it for the construction of main structural components such as beams, columns, and trusses. These elements form the framework for buildings, terminals, and platforms, ensuring stability and the ability to bear heavy loads. In airports, steel sees extensive use in the construction of hangars, terminals, and control towers. The lightweight nature of steel structures, combined with their high strength, allows for the creation of large open spaces and flexible designs. This proves especially crucial in airport terminals where there is a need for wide, open areas to accommodate a large number of passengers and support heavy mechanical and electrical systems. Steel is also employed in the construction of overhead walkways, escalators, and elevators, ensuring the safe movement of passengers within the airport. Similarly, in railway stations, steel plays a crucial role in the construction of platforms, bridges, and tunnels. Steel platforms provide a strong and stable surface for passengers to embark and disembark from trains. Steel bridges are commonly used to span over water bodies or other obstacles, enabling trains to pass through smoothly. Steel tunnels provide a protective enclosure for railway tracks, ensuring the safety of trains and passengers. Moreover, steel is chosen for transportation infrastructure due to its corrosion resistance properties, which prove particularly important in areas exposed to harsh weather conditions. Steel structures are often galvanized or coated with protective layers to prevent rust and deterioration, leading to an increased lifespan and reduced maintenance costs. Additionally, steel is valued for its fire-resistant properties in transportation infrastructure. Steel structures are designed to withstand high temperatures, providing a safe environment for passengers in case of fire emergencies. In conclusion, steel is an indispensable material in transportation infrastructure, including airports and railway stations, due to its strength, durability, versatility, corrosion resistance, and fire-resistant properties. Its use in constructing the main structural components ensures stability and load-bearing capacity, while also allowing for flexible designs and large open spaces. Overall, steel plays a vital role in the creation of safe and efficient transportation hubs for travelers worldwide.

- Q:How are steel structures designed for renewable energy facilities?

- The utilization of steel structures is widespread in the design of renewable energy facilities due to their exceptional strength, durability, and versatility. These structures are specifically created to provide crucial support for various components and equipment vital to the functioning of renewable energy systems, such as wind turbines, solar panels, and hydroelectric generators. In the case of wind turbines, engineers design steel towers to endure the dynamic forces exerted by the rotating blades while ensuring stability and support for the turbine. The design process of these towers meticulously takes into account factors such as wind speed, turbulence, and site-specific conditions. To ensure the tower's structural integrity and safety, advanced computer modeling and analysis techniques are employed. For solar power facilities, steel structures are employed to bear the weight of solar panels and racks. These structures are designed to withstand both static loads from the panels' weight and dynamic loads like wind and snow loads. The design also incorporates factors such as panel orientation, tilt angle, and sunlight exposure throughout the year to maximize energy production. In hydroelectric power plants, steel structures are also employed to provide support for turbines and generators. These structures must endure the forces generated by flowing water and offer stability for power generation equipment. The design process takes into consideration factors such as water flow rates, pressure, and turbine size to ensure efficient and safe operation. Throughout the design process, engineers carefully consider the specific requirements of each renewable energy facility, including its location, environmental conditions, and energy production objectives. Close collaboration with structural designers, architects, and other professionals is crucial to develop optimal steel structures that meet technical and safety standards while maximizing energy output. In summary, steel structures play a vital role in the design of renewable energy facilities, providing the necessary support, strength, and resilience required for the efficient and reliable operation of these systems.

- Q:What are the typical design considerations for steel industrial buildings?

- Some typical design considerations for steel industrial buildings include the structural stability and strength of the steel framework, the ability to withstand heavy loads and harsh weather conditions, proper ventilation and insulation for optimal working conditions, efficient use of space and layout for equipment and machinery, compliance with building codes and safety regulations, and the flexibility to accommodate future expansion or modifications.

- Q:What are the factors considered in determining the size and shape of steel members in a structure?

- The factors considered in determining the size and shape of steel members in a structure include the applied loads, such as dead loads, live loads, and wind loads, as well as factors such as safety, durability, and serviceability. Additionally, the design codes and standards, material properties, cost constraints, and construction methods also play a significant role in determining the size and shape of steel members.

- Q:How are steel structures used in the construction of zoos and animal enclosures?

- Due to their strength, durability, and versatility, steel structures are frequently employed in the construction of zoos and animal enclosures. One primary application of steel structures in zoos is for the creation of animal enclosures. These enclosures are typically spacious and necessitate a robust framework capable of supporting the weight of animals as well as any additional structures or equipment. Steel proves to be an ideal material for this purpose, boasting a high strength-to-weight ratio that permits the construction of large enclosures without excessive weight. Moreover, steel structures can be easily tailored and adjusted to meet the specific requirements of different animal species. For instance, the dimensions, contours, and heights of enclosures can be modified to accommodate animals of varying sizes and behaviors. Steel can also be employed to fabricate specialized features like climbing structures, perches, and platforms, providing a stimulating and enriching environment for the animals. In addition to animal enclosures, steel structures find application in the construction of various other facilities within zoos, including visitor viewing areas, walkways, and animal holding areas. Elevated walkways and viewing platforms can be created using steel, allowing visitors to observe animals from a safe distance while minimizing disruption to the animals' natural habitat. Furthermore, steel structures offer long-term durability, making them a cost-effective choice for zoo construction. Steel's resistance to corrosion, weathering, and pest damage ensures that the structures remain in excellent condition for many years with minimal maintenance. This durability proves especially crucial in zoos, where the structures must withstand the elements and the wear and tear caused by animals. In conclusion, steel structures are extensively utilized in the construction of zoos and animal enclosures due to their strength, durability, and versatility. They establish a safe and secure environment for animals while allowing for flexibility in design. Whether it involves constructing large enclosures, specialized features, or visitor facilities, steel structures play a vital role in ensuring the success and sustainability of zoos and animal habitats.

- Q:How are steel structures used in the construction of bars and pubs?

- Steel structures are commonly used in the construction of bars and pubs due to their numerous advantages. Steel is a strong and durable material that can support heavy loads, making it ideal for creating large open spaces and accommodating various design features. In the construction of bars and pubs, steel structures are often used for the framing and support systems. Steel beams and columns provide the necessary structural integrity to ensure the building can withstand the weight of the roof, floors, and walls. Additionally, steel is resistant to fire, which is crucial in establishments that serve alcohol and have a higher risk of accidents. The use of steel structures allows for greater flexibility in design. Steel can be molded and shaped into different forms, enabling architects and designers to create unique and appealing layouts. This versatility is particularly advantageous in bars and pubs where creating an inviting and visually appealing atmosphere is important. Another significant benefit of steel structures is their ability to span large distances without the need for intermediate support columns. This enables the creation of open floor plans, allowing for more efficient use of space and facilitating better sightlines for patrons. Furthermore, steel structures are often pre-fabricated off-site, reducing construction time and costs. This is particularly beneficial in the hospitality industry, where time is of the essence, and delays can impact revenue generation. The use of pre-fabricated steel components speeds up the construction process and minimizes disruption to the surrounding area. Steel structures also offer long-term cost savings. Steel is a low-maintenance material that does not require frequent repairs or replacements. It is resistant to pests, rot, and decay, making it an excellent choice for long-lasting and durable construction. In summary, steel structures play a vital role in the construction of bars and pubs. Their strength, durability, fire resistance, and versatility make them ideal for creating open and inviting spaces. Additionally, the use of steel structures allows for cost and time savings, making them a practical choice for the hospitality industry.

- Q:What are the guidelines for the maintenance and inspection of steel structures?

- To ensure the longevity, safety, and structural integrity of steel structures, it is crucial to prioritize their maintenance and inspection. The following guidelines can be followed for this purpose: 1. Schedule regular inspections of the steel structures by qualified professionals. It is recommended to conduct these inspections at least once a year, although the frequency may vary based on factors such as usage, location, and condition of the structure. 2. Conduct a thorough visual examination of the entire structure to identify any visible signs of damage, such as corrosion, cracks, or deformation. Pay attention to changes in color, texture, or appearance of the steel surfaces. 3. Implement effective corrosion protection measures to prevent steel degradation. This can be achieved by applying protective coatings such as paint or galvanization to the steel surfaces. Regularly inspect these coatings for signs of wear or damage and repair or reapply them as necessary. 4. Assess the structural stability of the steel components by checking for signs of movement, distortion, or misalignment. Pay attention to loose connections, bolts, or fasteners and tighten or replace them as needed. 5. Regularly verify the load capacity of the steel structures to ensure they can handle the intended loads. This can be done through calculations, stress analysis, or load testing, depending on the complexity and criticality of the structure. 6. Consider environmental factors that may impact the steel structures, such as exposure to moisture, chemicals, extreme temperatures, or seismic activity. Implement appropriate measures to mitigate these risks, such as proper drainage, insulation, or earthquake-resistant design. 7. Maintain detailed records of all inspections, maintenance activities, repairs, and modifications performed on the steel structures. This documentation will help track the structure's history and provide valuable information for future inspections and maintenance. 8. Engage experienced and qualified professionals for the maintenance and inspection of steel structures. These professionals should possess the necessary expertise, knowledge, and equipment to effectively identify and address any potential issues. Remember, while adhering to these guidelines is essential, it is also important to consult relevant codes, standards, and regulations specific to your region or industry. By conducting regular maintenance and inspections, you not only extend the lifespan of steel structures but also ensure the safety of the people and assets relying on them.

- Q:How are steel structures used in the construction of data centers?

- Steel structures are extensively used in the construction of data centers due to their strength, durability, and flexibility. They provide the necessary support and framework to accommodate heavy equipment, such as servers and cooling systems. Steel allows for large open spaces and wide floor spans, enabling efficient layout flexibility and easy expansion as data center needs evolve. Additionally, steel structures offer fire resistance, seismic resilience, and enhanced security, making them ideal for safeguarding critical data and ensuring the longevity of data center facilities.

- Q:What are the design considerations for steel waste management facilities?

- Considerations for designing steel waste management facilities include: 1. Ensuring Structural Integrity: The facility design must account for the weight and impact of waste materials, as well as the heavy machinery used in waste management operations. 2. Addressing Corrosion Concerns: Due to exposure to chemicals and moisture, the design should incorporate corrosion-resistant materials, coatings, or protective measures for long-term durability. 3. Emphasizing Ventilation and Odor Control: Proper ventilation systems are essential for preventing the buildup of hazardous gases and controlling odors. Compliance with health and safety regulations is crucial for employee safety and community impact. 4. Efficient Waste Segregation and Storage: The facility layout should facilitate the efficient segregation and storage of different types of waste, with clear labeling and signage to ensure proper waste management. 5. Prioritizing Fire Safety: Fire detection and suppression systems, along with fire-resistant construction materials, are necessary to minimize the risk and spread of fire, protecting the facility, surrounding areas, and personnel. 6. Ensuring Accessibility and Safety: Safe pathways for employees and waste management vehicles, suitable loading and unloading areas, and emergency vehicle access should be considered in the design. 7. Sustainability and Environmental Impact: The design should incorporate energy-efficient systems, waste recycling processes, and water conservation measures, while complying with environmental regulations to minimize pollution and contamination risks. 8. Future Expansion and Flexibility: The design should account for potential growth or changes in waste management operations, considering scalability, modular construction, or flexible layouts for future expansion or modifications. In conclusion, the design of steel waste management facilities should prioritize safety, efficiency, and environmental responsibility, meeting regulatory requirements and industry best practices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Structure Warehouse/Workshop GB Standard Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products