Steel Round Bar S355J2G3 Forged Round Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel Round Bar S355J2G3 Forged Round Steel

Product Information:

1.S355J2G3 forged round bar

2.size:280*5300mm

3.ut:sep1921-84D/d

4.heatreatment:annealed

5.straightness:2mm/m

6.Process: EAF+LF+VD (ESR furnace for optional)

7.Delivery condition: Hot forged, Heat-treatment (Normalized / Annealed / Quenched / tempered), Rough machining

8.Technical Data: Chemical Composition, Physical Properties and Mechanical Testing according to the customer's requirement

9.Test: Ultrasonic and magnetic test according to customer' require(EN or ASME and so on).

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

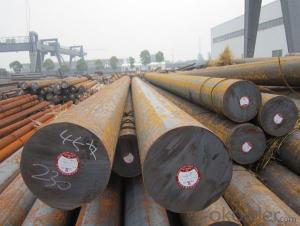

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q:How does special steel contribute to the manufacturing of hydraulic components?

- Special steel plays a crucial role in the manufacturing of hydraulic components by providing the required strength, durability, and corrosion resistance necessary for these components to perform optimally. The unique properties of special steel, such as high tensile strength and excellent machinability, ensure that hydraulic components can withstand high pressure and repetitive movements without deformation or failure. Additionally, the corrosion resistance of special steel helps protect hydraulic components from the harsh operating environments they often encounter, extending their lifespan and reducing maintenance requirements.

- Q:What are the different methods of surface powder coating for special steel?

- Some different methods of surface powder coating for special steel include electrostatic spraying, fluidized bed coating, and flame spraying. Electrostatic spraying involves applying a charged powder to the steel surface, which is then cured in an oven. Fluidized bed coating involves dipping the steel into a bed of powder that is heated to a fluidized state, allowing the powder to adhere to the surface. Flame spraying uses a flame to melt and propel the powder onto the steel surface, creating a durable coating.

- Q:What are the different coating techniques for special steel?

- There are several coating techniques commonly used for special steel, including electroplating, galvanizing, powder coating, thermal spraying, and chemical vapor deposition. Each technique offers unique advantages and is chosen based on the specific requirements of the steel, such as desired appearance, corrosion resistance, hardness, or wear resistance.

- Q:Can special steel be used in the construction equipment manufacturing industry?

- Yes, special steel can be used in the construction equipment manufacturing industry. Special steel, such as high-strength or wear-resistant steel, can provide enhanced durability and performance to construction equipment, making it suitable for demanding applications in the industry.

- Q:What are the specific requirements for special steel used in the textile machinery industry?

- The special steel requirements for the textile machinery industry can differ based on the specific application and machinery involved. Nevertheless, there are several common requirements in this industry. Firstly, corrosion resistance is crucial as textile machinery is frequently exposed to moisture, chemicals, and other corrosive substances. Therefore, the special steel used must possess excellent corrosion resistance properties to ensure durability and longevity. Secondly, high strength is necessary since textile machinery operates under high loads and stresses. Consequently, the special steel employed must have strong characteristics to withstand these forces and prevent deformation or failure. Furthermore, wear resistance is important as textile machinery involves constant contact between different components, leading to wear and tear. Thus, the special steel utilized should exhibit good wear resistance properties to minimize friction and extend the machinery's lifespan. Additionally, heat resistance is vital as textile machinery often operates at high temperatures due to friction generated during the manufacturing process. Consequently, the special steel used should possess exceptional heat resistance to prevent deformation or loss of mechanical properties under high temperature conditions. Moreover, machinability is necessary for the special steel used in the textile machinery industry. This allows for the production of complex components with precise dimensions, ensuring smooth and efficient machinery operation. Lastly, cost-effectiveness is crucial while meeting all the aforementioned requirements. Manufacturers strive to balance performance and cost to maintain competitiveness in the market without compromising on quality. It is important to note that these requirements can vary depending on the specific application within the textile machinery industry. As a result, manufacturers and engineers must carefully evaluate their machinery's requirements and choose the appropriate special steel accordingly.

- Q:How does special steel perform in oil and gas applications?

- Due to its outstanding performance and superior properties, special steel is highly sought after and extensively used in oil and gas applications. The exceptional resistance to corrosion exhibited by special steel is crucial in environments where oil and gas are present, as it helps prevent equipment failure and guarantees the longevity and reliability of the components. In addition, special steel possesses remarkable strength and durability, making it capable of withstanding extreme conditions such as high pressure and temperature. This strength enables the steel to endure the demanding and harsh environments often encountered in oil and gas applications. Moreover, special steel retains its mechanical properties even at elevated temperatures, ensuring stability and reliability in these challenging conditions. Another notable advantage of special steel is its excellent weldability. This property allows for easy fabrication and assembly of components, reducing production time and costs. It also ensures the integrity of the structures and equipment used in oil and gas applications. Furthermore, special steel offers exceptional resistance to fatigue and wear, which are commonly encountered issues in oil and gas operations. The ability of special steel to withstand cyclic loading and abrasive conditions guarantees the longevity and reliability of the components, thereby reducing maintenance and replacement costs. Overall, special steel performs exceptionally well in oil and gas applications due to its corrosion resistance, high strength, durability, weldability, and resistance to fatigue and wear. These superior properties make it the preferred choice for critical components, ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q:What are the properties of free-cutting steel?

- Free-cutting steel is characterized by its high machinability, which means it can be easily and efficiently machined into various shapes and sizes. It has excellent chip breaking properties, resulting in reduced tool wear and improved surface finish during machining operations. Free-cutting steel also has good formability, allowing it to be easily shaped and fabricated. Additionally, it exhibits high strength and good corrosion resistance, making it suitable for a wide range of applications in industries such as automotive, aerospace, and machinery manufacturing.

- Q:How does special steel contribute to the manufacturing of structural components?

- The unique properties and characteristics of special steel are crucial in the manufacturing of structural components. Firstly, its exceptional strength and durability make it an ideal material for load-bearing structures, as it can withstand high levels of stress, pressure, and heavy loads, ensuring their safety and integrity. In addition, special steel's excellent corrosion resistance is particularly important for structural components exposed to harsh environments. This feature helps prevent rusting and deterioration, thereby extending the lifespan of the components and reducing maintenance costs. Moreover, special steel offers a high degree of versatility in terms of design and fabrication. It can be easily shaped, molded, and welded, allowing manufacturers to create complex and intricate components with precision. This flexibility enables the production of customized components that meet specific requirements, enhancing the overall performance and functionality of the structures. Furthermore, special steel exhibits excellent heat resistance and fireproofing properties, making it suitable for components exposed to high temperatures or fire hazards. This is particularly important in industries such as industrial facilities, power plants, or transportation infrastructure, where fire protection is vital. Additionally, special steel often has superior fatigue resistance, allowing it to withstand repetitive or cyclic loading without suffering from fatigue failure. This property is crucial for components subjected to dynamic or fluctuating loads. In conclusion, special steel significantly contributes to the manufacturing of structural components by providing strength, durability, corrosion resistance, versatility in design, heat resistance, fireproofing, and fatigue resistance. Its unique properties make it an essential material choice for constructing safe, reliable, and long-lasting structures across various industries.

- Q:How does special steel contribute to the elasticity of products?

- Special steel contributes to the elasticity of products due to its unique composition and manufacturing process. The elasticity of a material refers to its ability to return to its original shape or size after being deformed or stretched. In the case of special steel, its specific properties enhance the elasticity of products in several ways. Firstly, special steel is often alloyed with elements such as nickel, chromium, or vanadium, which improve its mechanical properties. These alloying elements modify the crystal structure of the steel, resulting in a material that has a higher yield strength and tensile strength. This increased strength allows the steel to withstand higher levels of stress and deformation without permanent deformation or failure. Additionally, the manufacturing process of special steel involves precise control over its microstructure. Through techniques such as heat treatment and cold working, the steel's grain size and distribution are optimized. This controlled microstructure enhances the material's elasticity by promoting a uniform deformation mechanism. When a product made from special steel is subjected to external forces or stress, the steel's microstructure allows for the redistribution of these forces, minimizing localized deformation and maximizing overall elasticity. Furthermore, special steel often possesses a high carbon content, which contributes to its elasticity. The carbon atoms within the steel form strong chemical bonds with the iron atoms, resulting in a material with increased hardness and resistance to deformation. This enhanced resistance to deformation allows the steel to exhibit greater elasticity when subjected to external forces. Overall, special steel's unique composition, precise manufacturing processes, and specific alloying elements all contribute to its ability to enhance the elasticity of products. By incorporating special steel into the design and construction of various products, manufacturers can ensure that these products can withstand deformation and return to their original shape, thus increasing their durability and longevity.

- Q:How does special steel contribute to the defense and security industry?

- Special steel plays a crucial role in the defense and security industry by offering enhanced strength, durability, and resistance to extreme conditions. This type of steel is specifically designed to meet the unique demands of the industry, ensuring that military equipment and infrastructure can withstand the most challenging environments and threats. One significant contribution of special steel to the defense and security sector is in the manufacturing of armored vehicles and tanks. These vehicles require high-strength steel to protect military personnel from ballistic and explosive threats. Special steel provides the necessary toughness and resilience to withstand impacts, ensuring the safety of soldiers on the battlefield. Furthermore, special steel is also instrumental in the production of naval vessels and submarines. The maritime environment is highly corrosive, with saltwater and harsh weather conditions posing significant challenges. By utilizing special steel, naval ships can be constructed with superior corrosion resistance, extending their lifespan and reducing maintenance costs. In addition to its applications in vehicle and vessel manufacturing, special steel is vital for the production of military-grade weaponry and ammunition. The high strength and durability of this steel ensure that firearms, missiles, and other weapons can withstand extreme forces and function reliably in critical situations. This reliability is of utmost importance in the defense and security industry, where the failure of weapons could have severe consequences. Moreover, special steel also contributes to the construction of critical infrastructure for defense purposes. This includes structures such as military bases, bunkers, and communication towers. Special steel's ability to withstand extreme temperatures, high pressures, and other challenging conditions ensures the reliability and longevity of these structures, enhancing national security. In summary, special steel's unique properties, including high strength, durability, and resistance to extreme conditions, make it an essential component in the defense and security industry. By incorporating this material into military equipment, vehicles, weaponry, and infrastructure, defense organizations can ensure the safety, reliability, and effectiveness of their operations, ultimately contributing to national security.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Round Bar S355J2G3 Forged Round Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords