Steel Reinforcing Bar 5.5mm-32mm for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Reinforcing Bar 5.5mm-32mm for Building

Description for Reinforcing Bar:

| Reinforcing steel bars, rebar, Deformed steel bars | |||

| Size: | 8mm-32mm | Steel Grade: | HRB335, HRB400, HRB500, A615 Gr40, Gr60,BS4449 G460B, G500B JIS SD390, SD490, KS SD40, SD50 |

| Length: | 6m-12m | MOQ each size: | 200MT. |

| Loading port: | Tianjin or any other port china. | Packing: | in bundle. |

Payment term | LC , TT | Application: | Building, bridge , road or project construction |

Data for Reinforcing Bar:

HRB400 | Chemical Composition(%) | C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.045max | ||

Mechanical Property | Yield Strength | Tensile Strenth | Elongation | |||

| 400Mpa min | 540Mpa min | 16% | ||||

HRB500 | Chemical Composition(%)

| C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.045max | ||

| Mechanical Property | Yield Strength | Tensile Strength | Elongation | |||

| 500Mpa min | 630Mpa min | 15% | ||||

| HRB335 | Chemical Composition (%) | C | Mn | Si | P | S |

| 0.25max | 1.60max | 0.80max | 0.045max | 0.040max | ||

Mechanical Property | Yield Strength | Tensile strength | Elongation | |||

| 335Mpa min | 455Mpa min | 17% | ||||

Main Structure for Reinforcing Bar

Standard: AISI, ASTM, BS, DIN, GB, JIS, GOST

Grade: hrb335 hrb400 hrb500

Diameter: 5.5mm-32mm

Length: 6m-12m

Place of Origin: China (Mainland)

Model Number: 5.5mm-32mm

Application: contruction for project and building

steel reinforcing bar size: 5.5mm-32mm

steel reinforcing bar steel grade: hrb400 hrb500 hrb335 hpb300 q195

steel reinforcing bar length: 6mm-12mm

reinforcing bar MOQ:: 300MT for each size

FAQ:

Q: How’s your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

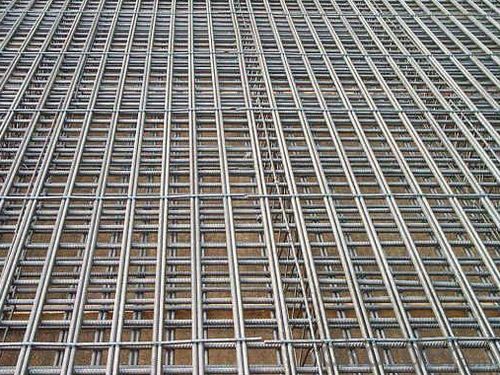

Picture:

- Q:What is the role of steel rebars in bridge deck construction?

- Steel rebars play a crucial role in bridge deck construction. They are used to reinforce the concrete used in the construction of the bridge deck. The main function of rebars is to provide tensile strength to the concrete, as concrete is strong in compression but weak in tension. Bridge decks are subjected to various loads, including the weight of the vehicles, live loads, and environmental factors such as temperature changes and vibrations. These loads can cause the bridge deck to bend, crack, or even collapse if it lacks sufficient tensile strength. By incorporating steel rebars into the bridge deck, the tensile strength of the concrete is significantly enhanced. The rebars are strategically placed throughout the concrete structure to distribute the loads and resist tension, thereby preventing cracks and ensuring the overall structural integrity of the bridge. In addition to reinforcing the concrete, steel rebars also help to control cracks that may occur due to shrinkage or thermal expansion. When the concrete shrinks or expands, it can lead to the formation of cracks, which can compromise the durability and stability of the bridge. However, the inclusion of rebars helps to control and limit the size and extent of these cracks, ensuring the long-term performance of the bridge. Furthermore, steel rebars also aid in the transfer of loads between different components of the bridge, such as the bridge deck and the supporting piers or abutments. They help to create a continuous load path, ensuring that the loads are efficiently transmitted and distributed throughout the bridge structure. In summary, steel rebars are essential in bridge deck construction due to their ability to provide the necessary tensile strength to the concrete. They enhance the structural integrity of the bridge, control cracks, and facilitate the transfer of loads, ultimately ensuring the safety and longevity of the bridge.

- Q:Can steel rebars be recycled after demolition?

- Yes, steel rebars can be recycled after demolition. Steel is one of the most commonly recycled materials in the world due to its durability and recyclability. After a building or structure is demolished, the steel rebars can be extracted and sent to recycling facilities. These facilities use various processes, such as shredding and melting, to separate the steel from other materials and reshape it into new products. Recycling steel rebars not only reduces the amount of waste sent to landfills but also conserves natural resources and helps to lower carbon emissions associated with steel production.

- Q:Are steel rebars corrosion-resistant?

- Yes, steel rebars are corrosion-resistant due to the protective oxide layer that forms on their surface, which helps prevent rusting and extends their lifespan.

- Q:What are the guidelines for preventing steel rebars from rusting during construction delays?

- To prevent steel rebars from rusting during construction delays, the following guidelines can be followed: 1. Store rebars in a clean, dry, and covered area to protect them from moisture and rain. 2. Use plastic or waterproof covers to shield rebars from direct contact with water or humidity. 3. Avoid stacking rebars directly on the ground to prevent them from absorbing moisture. 4. Apply a rust inhibitor or coating to the rebars to provide an additional layer of protection. 5. Regularly inspect the rebars during the construction delay to ensure they remain dry and rust-free. 6. If any signs of rust appear, remove the affected rebars and replace them with new ones. 7. Properly seal any concrete structures or foundations that contain rebars to prevent moisture penetration. 8. Keep the construction site clean, avoiding the accumulation of water or debris that could promote rust formation. By following these guidelines, construction delays can be managed effectively, minimizing the risk of rusting and ensuring the structural integrity of the steel rebars.

- Q:What are the different types of steel rebars used in airport construction?

- In airport construction, various types of steel rebars are employed to ensure the structural integrity and durability of the infrastructure. Some of the commonly used types of steel rebars in airport construction include: 1. Mild Steel Rebars: These rebars are the most basic and commonly used type of reinforcement in airport construction. They are made of carbon steel and have a smooth surface. Mild steel rebars provide general reinforcement and are suitable for various applications in airport runways, taxiways, and aprons. 2. High Strength Deformed (HSD) Steel Rebars: HSD rebars are treated with heat during the manufacturing process, resulting in enhanced strength and ductility. These rebars have ribbed surfaces that provide better adhesion to concrete, making them ideal for critical structural elements in airport construction, such as beams, columns, and foundations. 3. Epoxy-Coated Rebars: In environments where corrosion is a concern, epoxy-coated rebars are used. These rebars have a protective coating of epoxy resin that prevents the steel from coming into direct contact with moisture and chemicals present in concrete. Epoxy-coated rebars are commonly used in airport construction projects, especially in areas exposed to de-icing salts and other corrosive substances. 4. Stainless Steel Rebars: Stainless steel rebars offer excellent corrosion resistance and are commonly used in coastal airport locations or areas with high humidity. They are particularly suitable for reinforcing concrete structures in airport terminals, hangars, and other areas where aesthetics and durability are crucial. 5. Galvanized Rebars: Galvanization involves coating the steel rebar with a layer of zinc to provide protection against corrosion. Galvanized rebars are commonly used in areas with high moisture content or where the concrete is exposed to harsh weather conditions. They are commonly employed in airport construction projects for reinforcing structures like retaining walls, drainage systems, and other external components. 6. Welded Wire Fabric (WWF): Welded wire fabric consists of a series of parallel and perpendicular steel wires welded together to form a mesh-like structure. This type of rebar is used in airport construction for concrete slabs, pavements, and other large surface areas. WWF provides uniform reinforcement and helps distribute loads evenly across the structure. It's important to note that the choice of steel rebars in airport construction depends on factors such as the specific application, structural requirements, environmental conditions, and local building codes. Consulting with structural engineers and construction professionals is crucial to determine the most appropriate type of steel rebar for each specific application in airport construction projects.

- Q:Can steel rebars be used in water treatment plant construction?

- Yes, steel rebars can be used in water treatment plant construction. Steel rebars are commonly used in the construction of various structures, including water treatment plants, due to their high strength and durability. They provide reinforcement to concrete structures and ensure their integrity and longevity, making them suitable for use in water treatment plant construction.

- Q:How do steel rebars improve the structural integrity of concrete?

- Steel rebars improve the structural integrity of concrete by providing reinforcement and added strength to the material. They are embedded within the concrete, acting as a framework that helps to distribute and carry loads more effectively, preventing cracks and enhancing the overall durability and stability of the structure.

- Q:Can steel rebars be used in the construction of hospitals?

- Yes, steel rebars can be used in the construction of hospitals. Steel rebars are commonly used in reinforced concrete structures to provide strength and stability. In hospital construction, where safety and durability are crucial, steel rebars are essential for reinforcing concrete foundations, columns, beams, and other structural elements. They help ensure the structural integrity of the hospital building, making it resilient and capable of withstanding various loads and potential hazards.

- Q:How do steel rebars contribute to the overall ductility of a structure?

- The overall ductility of a structure is significantly improved by steel rebars in various ways. To begin with, steel rebars possess high flexibility and can endure substantial stress before yielding or breaking. This flexibility enables them to absorb and distribute the applied load, minimizing the risk of sudden failure or collapse. By reinforcing the concrete, rebars assist the structure in withstanding external forces like earthquakes or extreme weather conditions. Furthermore, rebars augment the tensile strength of the concrete. Although concrete is renowned for its impressive compressive strength, its tensile strength is relatively low. When stress is exerted on a structure, rebars aid in resisting tension forces and averting cracking or failure. This ensures that the structure can withstand both compressive and tensile forces, thereby bolstering its overall durability and safety. Moreover, steel rebars also bolster the structural integrity by impeding the propagation of cracks. When a crack initiates in a concrete element, the rebars act as a barrier, restraining the crack's expansion and preventing rapid dissemination. This characteristic of rebars helps to uphold the overall stability and integrity of the structure. Additionally, steel rebars offer a greater degree of flexibility during construction. They can be easily bent, shaped, and joined to meet specific design requirements, granting architects and engineers the ability to create structures that are more aesthetically pleasing and functional. This flexibility also facilitates the construction process by allowing modifications or adjustments to be made without compromising the overall strength or stability of the structure. In conclusion, steel rebars play an indispensable role in enhancing the ductility of a structure. They heighten the tensile strength, absorb and distribute stress, impede crack propagation, and provide flexibility during construction. These properties contribute to the overall durability, safety, and structural integrity of a building or infrastructure, establishing steel rebars as an essential component in contemporary construction practices.

- Q:Can steel rebars be painted or coated?

- Yes, steel rebars can be painted or coated. Painting or coating steel rebars is a common practice in construction and engineering to provide protection against corrosion and to enhance their aesthetic appearance. The process involves applying a layer of paint or coating material onto the surface of the rebars. This coating acts as a barrier, preventing moisture and other corrosive elements from reaching the steel surface, thus prolonging the lifespan of the rebars. Additionally, painting or coating the rebars can also help in differentiating them from other construction materials or providing color-coding for identification purposes. It is important to use high-quality paint or coating materials that are specifically designed for steel applications to ensure proper adhesion and durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Reinforcing Bar 5.5mm-32mm for Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords