Steel rail high quality for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

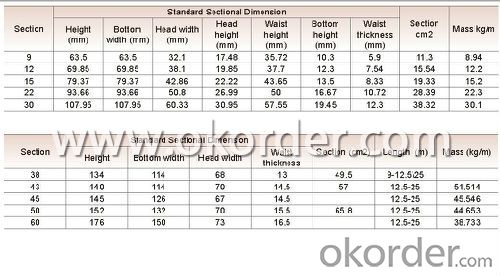

Specifications of High Quality Steel Rail

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Applications of High Quality Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of High Quality Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of High Quality Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:Can steel rails be used in high-speed rail systems?

- Yes, steel rails can be used in high-speed rail systems. Steel rails are commonly used in high-speed rail systems around the world due to their durability, strength, and ability to withstand the high speeds and heavy loads. Additionally, steel rails provide a smooth and stable track for trains, ensuring safe and efficient operations in high-speed environments.

- Q:What is the average lifespan of a steel rail in a subway system?

- The average lifespan of a steel rail in a subway system can differ based on several factors, including the type of rail, the intensity of subway system usage, maintenance practices, and environmental conditions. Typically, steel rails in subway systems are built to endure for 25 to 50 years. Nevertheless, certain steel rails have been documented to surpass this lifespan thanks to appropriate maintenance and regular inspections. It should be emphasized that regular maintenance, such as grinding and replacing worn rails, is crucial for guaranteeing the endurance and safety of the rail infrastructure in a subway system.

- Q:How are steel rails inspected for defects and damages?

- Steel rails are inspected for defects and damages through a combination of visual inspections, ultrasonic testing, and magnetic particle testing. Visual inspections involve visually examining the rails for any visible signs of defects or damages, such as cracks, breaks, or abnormalities. Ultrasonic testing uses high-frequency sound waves to detect internal flaws or cracks in the rails that may not be visible to the naked eye. Magnetic particle testing involves applying a magnetic field to the rails and then applying iron particles to detect any surface cracks or defects. These inspection methods help ensure the safety and reliability of steel rails for transportation purposes.

- Q:How are steel rails affected by changes in track alignment?

- Steel rails can be affected by changes in track alignment, which can lead to various consequences. Initially, sudden shifts or misalignments in the track can exert excessive stress on the steel rails, causing them to wear down more quickly. This can result in cracks, breaks, or deformations in the rails, which undermines their structural integrity. Furthermore, alterations in track alignment can also impact how forces are distributed on the steel rails. When the track alignment is not smooth, the weight of the train and the forces generated during its movement may not be evenly spread across the rails. Consequently, certain sections of the rails may bear more weight, leading to accelerated wear and the possibility of rail failure. Additionally, changes in track alignment can influence the overall stability and comfort of train rides. Misaligned tracks can produce excessive vibrations and impacts, which can cause discomfort for passengers and harm to the rolling stock. This can result in higher maintenance costs and decreased operational efficiency. Moreover, changes in track alignment can affect the safety of train operations. Misaligned tracks can heighten the risk of derailments, especially when trains are traveling at higher speeds. Proper track alignment is crucial for ensuring the safe and efficient movement of trains, and any deviations from the desired alignment can compromise the overall safety of the rail system. Overall, changes in track alignment can have negative effects on steel rails, including increased wear and tear, compromised structural integrity, uneven distribution of forces, reduced stability and comfort, and potential safety hazards. Therefore, regularly monitoring and maintaining track alignment is essential to guarantee the longevity, efficiency, and safety of steel rails in railway systems.

- Q:Can steel rails be used in underground stations?

- Yes, steel rails can be used in underground stations. In fact, steel rails are commonly used in underground railways due to their durability, strength, and ability to withstand heavy loads. They provide stability and smoothness for train movement, ensuring safe and efficient transportation within underground stations.

- Q:Can steel rails be used for curved tracks?

- Curved tracks can indeed utilize steel rails. Steel is widely used in railway tracks due to its durability, strength, and resistance to wear and tear. To accommodate curved tracks, steel rails can be specially designed and manufactured with a specific shape that enables smooth and safe navigation around the curves. Typically, these curved steel rails are bent or shaped to match the desired curvature of the track, ensuring that trains can travel smoothly and efficiently without causing derailments or excessive wear on the wheels or tracks. Moreover, the use of steel rails for curved tracks allows for higher speeds and enhanced stability during turns, making it a preferred choice for railway systems worldwide.

- Q:What are the factors that can cause steel rail failure?

- There are several factors that can contribute to steel rail failure. One of the main factors is fatigue, which occurs due to repeated loading and unloading of the rail as trains pass over it. Over time, this cyclic loading can lead to the development of cracks and fractures in the rail, ultimately resulting in failure. Another factor that can cause steel rail failure is wear. As trains travel over the rail, the wheels exert pressure on the surface, leading to gradual wear and tear. If the rail is not properly maintained or if the trains exceed the recommended weight limits, the wear can become severe enough to cause failure. Corrosion is also a significant factor that can contribute to steel rail failure. When exposed to moisture and other environmental elements, the rail can start to corrode. This corrosion weakens the structure of the rail, making it more prone to cracking and breaking under the weight of passing trains. Improper maintenance practices can also lead to rail failure. If the rail is not regularly inspected, any issues such as cracks or wear may go unnoticed, allowing them to worsen over time. Additionally, inadequate lubrication between the rail and the train wheels can increase friction and wear, accelerating the deterioration of the rail. Lastly, extreme weather conditions can play a role in causing steel rail failure. For instance, heavy rainfall can lead to soil erosion, which can destabilize the rail and cause it to shift or sink. Similarly, freezing temperatures can cause the rail to contract and become more brittle, increasing the likelihood of failure. In conclusion, factors that can cause steel rail failure include fatigue, wear, corrosion, improper maintenance, and extreme weather conditions. It is crucial to regularly inspect and maintain the rail infrastructure to prevent these factors from compromising its integrity and ensuring safe and efficient train operations.

- Q:How are steel rails protected from extreme weather conditions?

- Steel rails are protected from extreme weather conditions through various measures such as galvanization, paint coatings, and regular maintenance. Galvanization involves applying a layer of zinc to the steel rails, which forms a protective barrier against corrosion caused by moisture or exposure to harsh weather elements. Additionally, paint coatings are applied to further shield the rails from moisture, ultraviolet rays, and other damaging factors. Regular maintenance, including inspections and repairs, helps identify and address any potential weather-related issues promptly, ensuring the long-term durability and safety of the steel rails.

- Q:High iron seamless rail is how to solve the problem of the thermal contraction account?

- The seamless line is divided into a fixed area, expansion area, buffer, the buffer can be reserved for the large number of rail joints for expansion, expansion area adjacent to the buffer, if the buffer rail gap due to seasonal changes is not enough, the rail to replace the different length in the expansion area to adjust the rail gap.

- Q:How do steel rails affect noise pollution?

- Noise pollution is significantly affected by steel rails in various ways. Firstly, the passing of trains causes vibrations, resulting in noise production. As trains travel on the tracks, the wheels create vibrations that are transmitted through the steel rails, creating a rumbling sound. This noise becomes particularly noticeable in areas with curved tracks or joints between rail sections. Moreover, steel rails amplify the noise produced by the train wheels. The hard and smooth surface of steel rails reflects and magnifies sound waves, making the noise louder and more noticeable. This effect is especially pronounced in urban areas where buildings and structures act as echo chambers, intensifying the noise pollution caused by steel rails. Furthermore, noise pollution is also influenced by the maintenance and condition of steel rails. Regular maintenance, such as rail grinding or lubrication, is crucial to minimize noise generation. Improper maintenance can lead to increased noise levels as the train wheels interact with irregularities on the rail surface. Efforts have been made in recent years to mitigate noise pollution caused by steel rails. Various measures have been implemented, including the installation of noise barriers along railway lines, the use of noise-dampening materials on the track bed, and the employment of noise-reducing rail fastening systems. These measures aim to minimize the noise impact on nearby residents and reduce overall noise pollution in the surrounding environment. In conclusion, steel rails have a significant impact on noise pollution due to vibrations and sound amplification. However, technological advancements and the implementation of noise-reducing measures are helping to minimize the noise impact of steel rails and improve the quality of life for those living near railway lines.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel rail high quality for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords