Steel prop & Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp:

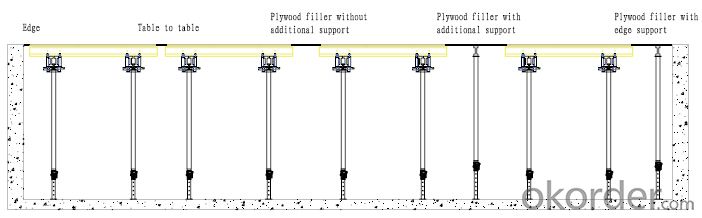

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Can steel props be used for scaffolding purposes?

- Yes, steel props can be used for scaffolding purposes. Steel props are commonly used to support and stabilize scaffolding structures due to their strength, durability, and adjustable height capabilities. They provide a reliable and secure support system for construction workers and materials on scaffolding platforms.

- Q:What are the load testing procedures for steel props?

- The load testing procedures for steel props typically involve applying incremental loads to the prop until it reaches its maximum capacity. The load is usually increased in predetermined increments and held for a specified duration to ensure the prop can withstand the intended load. The prop is visually inspected before and after the test, and any deformations or failures are noted. This process helps determine the maximum load-bearing capacity of the steel prop and ensures its safety and reliability in real-world applications.

- Q:How do you protect steel props from environmental damage?

- To protect steel props from environmental damage, it is important to implement proper preventive measures. This can include applying protective coatings such as paint, varnish, or rust-resistant coatings to the steel props. Regular inspections should also be conducted to identify any signs of corrosion or damage, and prompt repairs or replacements should be carried out. Additionally, storing the steel props in a dry and well-ventilated area when not in use can help prevent exposure to moisture and other environmental elements that may cause damage.

- Q:Are steel props commonly used in residential construction?

- No, steel props are not commonly used in residential construction. Residential construction typically involves the use of wooden or concrete supports, known as scaffolding, to provide structural support during the construction process. Steel props, also known as adjustable steel columns or acrow props, are more commonly used in commercial or industrial construction projects where heavier loads and taller structures are involved. They are generally used to support beams or floors during construction or renovation work. However, it is important to note that construction methods and materials can vary depending on location and specific project requirements, so it is possible that steel props could be used in certain residential construction scenarios.

- Q:Can steel props be used in marine or underwater applications?

- When using steel props in marine or underwater settings, certain precautions must be taken to ensure their effectiveness and durability. Generally, steel props are utilized to provide support and stability to structures, such as buildings or temporary structures like scaffolding, during construction or renovations. To withstand the harsh conditions of saltwater or other corrosive substances, the steel props in marine or underwater applications should be constructed from corrosion-resistant materials like stainless steel or galvanized steel. Regular maintenance and inspections are also vital to detect and address any signs of corrosion or damage. In addition, the design and installation of steel props in marine or underwater environments should consider the specific challenges they will face. Factors like water pressure, currents, and waves must be taken into account. To ensure stability and prevent potential hazards, adequate anchoring and bracing methods must be employed. It is important to mention that there may be alternative materials or specialized equipment specifically designed for marine or underwater applications that may be more suitable and efficient than steel props. Therefore, it is advisable to seek guidance from experts or professionals experienced in marine engineering and construction to determine the most appropriate solution for a specific project.

- Q:Can steel props be used for temporary support in residential buildings?

- Yes, steel props can be used for temporary support in residential buildings. Steel props are commonly used in construction to provide temporary support during building works, renovations, or repairs. They are adjustable and can bear heavy loads, making them suitable for providing temporary support in residential buildings where additional support is needed.

- Q:How do you store and transport steel props?

- Steel props can be stored by stacking them in a dry and well-ventilated area, ensuring that they are not exposed to moisture or extreme temperatures. To transport steel props, they should be secured properly using straps or chains on a flatbed truck or in a suitable container to prevent any movement or damage during transportation. It is important to follow safety guidelines and regulations while storing and transporting steel props to ensure their longevity and prevent any accidents.

- Q:How do steel props compare to hydraulic jacks in terms of functionality?

- Steel props and hydraulic jacks serve similar purposes but differ in terms of functionality. Steel props, also known as adjustable steel props or steel shore props, are telescopic support systems commonly used in construction to provide temporary support to beams, walls, and ceilings. They are manually adjustable and can be easily extended or contracted to the desired height, offering stability and load-bearing capacity. On the other hand, hydraulic jacks rely on hydraulic pressure to lift and support heavy loads. They are typically used for lifting vehicles, machinery, or heavy objects in industries such as automotive repair, manufacturing, and construction. Hydraulic jacks offer greater lifting capacity and precision control compared to steel props, making them more suitable for heavy-duty applications. Overall, while steel props are versatile and efficient in providing temporary support in construction, hydraulic jacks excel in heavy lifting tasks due to their higher load-bearing capacity and hydraulic control. The choice between the two depends on the specific requirements and nature of the task at hand.

- Q:What are the components of a steel prop?

- The components of a steel prop typically include a steel tube or pipe, an adjustable threaded collar, a base plate or foot, and a swivel head or top plate.

- Q:Do steel props require any special tools for installation?

- Yes, steel props typically require special tools for installation, such as spanners, wrenches, and hammers. These tools are used to adjust the height and secure the props in place, ensuring stability and safety during construction or renovation projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel prop & Tripod & Beam clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords