Steel Prop & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

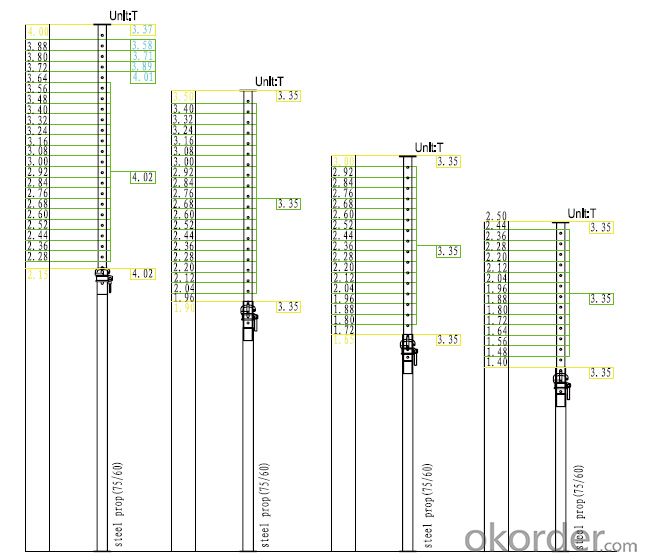

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Can steel props be used for supporting temporary art installations?

- Yes, steel props can be used for supporting temporary art installations. Steel props are strong and durable, making them suitable for providing stability and structural support to various types of art installations. Additionally, their adjustable and customizable nature allows artists to create unique and secure displays, ensuring the safety of the artwork and the surrounding environment.

- Q:Are steel props suitable for temporary structures?

- Temporary structures can be supported by steel props, also called adjustable steel props or acrow props. These props are commonly used in construction projects to provide stability and load-bearing capacity for structures like formwork, scaffolding, and shoring systems. The versatility of steel props lies in their adjustable height feature, which allows them to support different structures precisely. Made from high-quality steel, these props are durable and strong, capable of handling heavy loads and providing reliable temporary support. In terms of efficiency, steel props are easy to install and dismantle. They can be quickly adjusted to the desired height and removed once the temporary structure is no longer needed. This flexibility and user-friendliness have made them a popular choice in the construction industry. However, it is crucial to consider factors such as the size, weight, and duration of use when determining the suitability of steel props for temporary structures. Consulting with a structural engineer or construction professional is always advised to ensure the proper selection and usage of steel props for such projects.

- Q:Are steel props resistant to electromagnetic pulses (EMP)?

- No, steel props are not resistant to electromagnetic pulses (EMP). EMPs can induce high voltage currents in conductive materials like steel, which can cause damage to electronic devices or systems connected to the steel props.

- Q:Can steel props be used for supporting heavy machinery or equipment?

- Steel props are capable of supporting heavy machinery or equipment. They possess strength and durability, making them a suitable option for offering temporary support to heavy loads. Often utilized in construction and engineering ventures, these props effectively support the weight of equipment like cranes, scaffolding, and formwork systems. The height of steel props can be adjusted, allowing for customization according to the specific needs of the equipment being supported. Moreover, their installation and removal are effortless, providing flexibility in their utilization. In conclusion, steel props are a dependable and efficient solution for supporting heavy machinery or equipment.

- Q:What are the limitations of using steel props?

- Using steel props in construction and temporary support systems comes with several limitations. These limitations include: 1. Weight and handling: Steel props can prove to be cumbersome and challenging to transport, especially in confined spaces or when working on higher levels of a building. Manipulating and adjusting their position during installation and removal can also be difficult due to their weight. 2. Limited adjustability: Although steel props offer some adjustability, it may not be sufficient for all applications. Adjusting their height can be time-consuming and may require additional tools or equipment. 3. Load capacity: Steel props have a restricted load-bearing capacity. Depending on the type and size of the prop, they may not be able to support heavy loads or withstand excessive forces. This limitation can restrict their use in construction projects that require extensive structural support. 4. Corrosion: Steel props are prone to corrosion when exposed to moisture, chemicals, or harsh environmental conditions. Failure to properly maintain or protect them can weaken their overall strength and stability over time. 5. Limited structural versatility: Steel props are primarily designed for vertical support and may not be suitable for unconventional building layouts or certain structural configurations. They may not provide adequate stability or alignment in non-standard situations, necessitating the use of alternative support systems. 6. Cost: Steel props can be expensive to purchase or rent, particularly for long-term projects or when a large number of props are needed. The cost of transportation, storage, and maintenance should also be taken into account when considering the use of steel props. 7. Safety concerns: Proper installation and regular inspections are crucial to ensuring the security and stability of steel props. Neglecting these measures can lead to accidents, injuries, or structural damage. Moreover, steel props can pose a tripping hazard if not positioned or secured correctly. It is essential to carefully evaluate the specific requirements of a project and consider alternative support systems when necessary to overcome the limitations associated with using steel props.

- Q:How do you ensure proper alignment of steel props?

- Achieving proper alignment of steel props can be accomplished by following several steps: 1. Inspection: Before use, thoroughly examine the steel props for any indications of damage or defects. Inspect for any bent or dented components, signs of rust or corrosion, and confirm that all locking pins and fasteners are securely in place. 2. Leveling: Position the steel props on a stable and even surface. Utilize a spirit level or laser level to verify the vertical alignment of the props. Adjust the base plates or footings as needed to ensure they are sitting squarely on the ground. 3. Plumb line: Employ a plumb line or plumb bob to assess the vertical alignment of the steel props. Attach the plumb line to the top of the prop, allowing it to hang freely. Confirm that the line is perfectly vertical and make adjustments to the prop as necessary to achieve proper alignment. 4. Bracing: Maintaining alignment and stability of the steel props depends on proper bracing. Install diagonal braces between the props to prevent lateral movement or collapse. These braces should be securely fastened and regularly inspected to ensure they are not loose or damaged. 5. Regular checks: Throughout the project duration, consistently inspect the steel props to ensure they remain correctly aligned. This involves checking for any signs of movement, loose connections, or shifting of the props. If any issues are identified, take immediate action to rectify them. 6. Removal: When removing the steel props, adhere to appropriate procedures to prevent sudden movement or collapse. Always ensure that the load is fully supported by an alternative means before removing the props. This safeguards against misalignment or damage during the removal process. By adhering to these steps, one can guarantee the proper alignment of steel props, which is vital for the safety and stability of the supported structure.

- Q:How do you adjust the height of a steel prop?

- To adjust the height of a steel prop, you need to follow a systematic process. Here are the steps to adjust the height of a steel prop: 1. Inspect the prop: Before adjusting the height, ensure that the steel prop is in good condition and not damaged. Check for any cracks, bends, or defects that may affect its stability. 2. Determine the required height: Measure the distance between the ground or supporting surface and the desired height for the prop. This will help you determine how much adjustment is needed. 3. Loosen the locking mechanism: Most steel props have a locking mechanism, usually a pin or a collar, to secure the height adjustment. Locate this mechanism and loosen it to allow movement of the prop. 4. Adjust the height: Depending on the type of steel prop, there are different ways to adjust the height. If it is a telescopic prop, you can extend or retract the sections to achieve the desired height. For a screw-type prop, rotate the threaded rod clockwise or counterclockwise to raise or lower the prop respectively. 5. Secure the adjusted height: Once you have set the correct height, tighten the locking mechanism to secure the prop in place. Ensure that it is firmly locked to prevent any accidental movement. 6. Test stability: After adjusting the height, check the stability of the prop by applying some weight or pressure on it. Ensure that it remains steady and does not wobble or shift. If there are any stability issues, reassess the height adjustment and make necessary corrections. Remember to exercise caution and follow the manufacturer's guidelines when adjusting steel props. If you are unsure or inexperienced, it is advisable to seek assistance from a professional or someone with expertise in using steel props.

- Q:Do steel props require any special storage or handling procedures?

- Yes, steel props do require special storage and handling procedures. Steel props are commonly used in construction projects to provide temporary support to structures during construction or renovations. To ensure their longevity and safety, it is important to follow certain procedures when storing and handling steel props. Firstly, proper storage is crucial to protect steel props from environmental factors that can cause corrosion or damage. Steel props should be stored in a dry and well-ventilated area, away from moisture or direct sunlight. If they are not in use, it is recommended to keep them indoors or under a waterproof cover. Additionally, it is important to handle steel props carefully to prevent any accidents or injuries. When lifting or moving steel props, it is advisable to use appropriate lifting equipment such as cranes or forklifts, instead of manually lifting them. This ensures the props are not dropped, leading to potential damages or injuries. Furthermore, it is essential to inspect steel props before and after each use. Any signs of damage, including deformations, cracks, or excessive wear, should be addressed immediately. Damaged steel props should not be used and should be replaced or repaired to maintain the structural integrity and safety of the construction site. In conclusion, steel props do require special storage and handling procedures to ensure their longevity and safety. Following proper storage methods and handling practices, as well as regular inspections, will help prevent damage and maintain the quality of steel props, ultimately contributing to a safe and efficient construction process.

- Q:Are steel props suitable for supporting temporary tents?

- Yes, steel props are suitable for supporting temporary tents. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary structures to provide support and stability. They are made of high-quality steel and are designed to withstand heavy loads and provide maximum strength and durability. Steel props are adjustable in height, allowing for easy customization to suit different tent sizes and terrain conditions. They are also easy to install and remove, making them a convenient option for temporary tent setups. Additionally, steel props provide excellent stability and can withstand various weather conditions, ensuring the safety and integrity of the tent structure.

- Q:How do you transport steel props to different construction sites?

- Transporting steel props to different construction sites can be done in several ways, depending on the quantity and size of the props. Here are a few common methods: 1. Flatbed trucks: Steel props can be loaded onto flatbed trucks and secured using straps or chains to prevent movement during transportation. This method is suitable for larger quantities of steel props or when the props are too heavy to be lifted manually. 2. Crane trucks: If the steel props are particularly heavy or large, a crane truck can be used to lift and load them onto the truck bed. This method ensures safe and efficient transportation, especially when dealing with oversized props. 3. Shipping containers: For longer distance transportation, especially when exporting or importing steel props, shipping containers can be used. The props can be stacked and secured inside the container, ensuring they are protected from external elements during transit. 4. Trailers: Smaller quantities of steel props or props of varying sizes can be transported using trailers. These trailers can be attached to a truck or van and provide a convenient and cost-effective way of transporting props to different construction sites. Regardless of the method chosen, it is crucial to ensure proper securing of the steel props during transportation to prevent any damage or accidents. Regular inspection of the props and the chosen transportation method is also necessary to ensure compliance with safety regulations and to maintain the integrity of the steel props.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Prop & Beam Clamp formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords