Steel Prop & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Steel Prop & Tripod & Beam Clamp

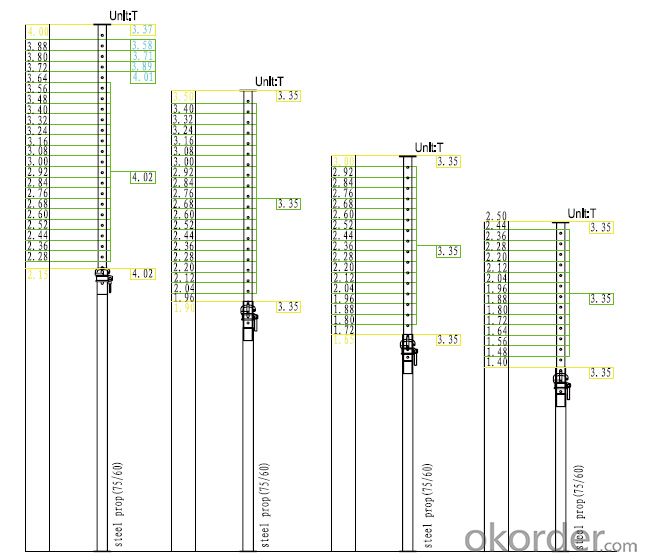

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q:Can steel props be used for temporary support during renovations?

- Yes, steel props can certainly be used for temporary support during renovations. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and renovation projects to provide temporary support to structures. These props are adjustable in height, making them versatile and suitable for various applications. During renovations, when walls or other supporting structures need to be removed or modified, steel props can be used to provide temporary support until the necessary work is completed. They are typically placed beneath beams, ceilings, or floors to prevent any potential collapse or structural damage. Steel props are known for their strength, stability, and load-bearing capacity. They are designed to withstand heavy loads and provide reliable support, ensuring the safety of workers and the structure itself during renovations. The adjustable feature of these props allows for precise height adjustment, ensuring a proper fit and support for different construction and renovation requirements. In addition to their strength and adjustability, steel props are also easy to install and remove. This makes them a convenient choice for temporary support during renovations, as they can be quickly set up and dismantled as needed. Overall, steel props are a reliable and commonly used solution for temporary support during renovations. They provide stability, load-bearing capacity, and versatility, making them suitable for a wide range of construction and renovation projects.

- Q:Can steel props be used for temporary support during beam installation?

- Yes, steel props can be used for temporary support during beam installation. Steel props are commonly used in construction projects to provide temporary support to structures or components like beams. They are adjustable, strong, and can safely bear the load of the beam during installation.

- Q:How do steel props accommodate for changes in temperature and weather conditions?

- Steel props accommodate for changes in temperature and weather conditions through their inherent strength and durability. The high tensile strength of steel allows it to withstand extreme temperatures without significant deformation or structural failure. Additionally, steel props are often galvanized or treated with protective coatings, which enhance their resistance against corrosion and moisture damage caused by weather conditions.

- Q:What are the guidelines for the proper storage and handling of steel props?

- The guidelines for the proper storage and handling of steel props are as follows: 1. Storage: Steel props should be stored in a dry and well-ventilated area to prevent rust and corrosion. They should be kept away from moisture, direct sunlight, and extreme temperatures. 2. Handling: When handling steel props, it is essential to ensure proper lifting techniques are employed. The props should be lifted using appropriate lifting equipment, such as cranes or forklifts, to avoid injury and damage. It is important to distribute the weight evenly and handle the props with care to prevent any bending or distortion. 3. Inspection: Before storage or use, steel props should be inspected for any visible damage, such as cracks, dents, or excessive wear. If any defects are found, the props should not be used and must be repaired or replaced promptly. 4. Cleaning: Steel props should be cleaned regularly to remove dirt, debris, and any contaminants that may accelerate corrosion. A soft brush or cloth can be used to clean the props, and a mild detergent or metal cleaner can be applied if necessary. After cleaning, the props should be thoroughly dried to prevent moisture build-up. 5. Stacking: When storing steel props, they should be stacked horizontally, with each prop aligned and spaced evenly. Care should be taken to ensure that the weight is evenly distributed to avoid any bending or damage to the props. 6. Protection: To protect steel props from moisture and corrosion during storage, they should be covered with a tarpaulin or plastic sheet. This will help to prevent any water or moisture from coming into contact with the props. 7. Separation: Steel props should be stored separately from other materials or equipment that may cause damage, such as sharp objects or chemicals. Proper separation will help prevent scratches, dents, or chemical reactions that could compromise the integrity of the props. By following these guidelines, the proper storage and handling of steel props can be ensured, prolonging their lifespan and maintaining their structural integrity for safe and efficient use.

- Q:Can steel props be used for temporary support in underground parking structures?

- Steel props are an option for temporary support in underground parking structures. Their frequent use in construction projects is due to their strength, durability, and adjustability. These qualities make them well-suited for supporting the weight and load of the structure during construction or renovation. Additionally, steel props can be easily installed and adjusted to the necessary height, providing stability and security until permanent supports are established. Nevertheless, it is crucial to consult a structural engineer to guarantee proper design and installation that align with the specific requirements and safety standards of the underground parking structure.

- Q:Can steel props be used for temporary support in telecommunications tower construction?

- Yes, steel props can be used for temporary support in telecommunications tower construction. Steel props are often used in construction projects to provide temporary support to structures or components during various stages of the construction process. In the case of telecommunications tower construction, steel props can be used to provide additional stability and support to the tower during the initial construction phase. These props can be adjusted and positioned as needed to ensure that the tower remains stable and secure during the construction process. Once the tower construction is complete and it is able to stand on its own, the steel props can be removed. Overall, steel props can be a reliable and effective solution for providing temporary support in telecommunications tower construction.

- Q:How do you prevent steel props from tipping over?

- One way to prevent steel props from tipping over is by ensuring they are properly braced and supported. This can be achieved by using diagonal bracing or cross bracing, which adds stability and prevents lateral movement. Additionally, securing the props to a stable surface or using weighted bases can provide extra support and prevent tipping. Regular inspections and maintenance to identify any signs of instability or wear are also crucial in preventing accidents.

- Q:Can steel props be used for temporary support during pipe rack installation?

- Yes, steel props can be used for temporary support during pipe rack installation. Steel props provide sturdy and reliable support, making them suitable for holding the weight of the pipes during installation.

- Q:Do steel props require any special storage or handling procedures?

- Special storage and handling procedures are necessary for steel props. In construction projects, steel props are commonly utilized to temporarily support structures during construction or renovations. To ensure their durability and safety, it is crucial to adhere to specific procedures when it comes to storing and handling steel props. First and foremost, proper storage is vital in order to shield steel props from environmental factors that may cause corrosion or damage. It is recommended that steel props be stored in a dry and well-ventilated area, away from moisture or direct sunlight. If not in use, they should be kept indoors or covered with a waterproof material. Furthermore, careful handling of steel props is of utmost importance to prevent accidents or injuries. Instead of manually lifting them, it is advisable to use appropriate lifting equipment such as cranes or forklifts when lifting or moving steel props. This ensures that the props are not dropped, which could result in potential damage or injuries. Moreover, it is essential to conduct inspections of steel props both before and after each use. Any indications of damage, such as deformations, cracks, or excessive wear, should be promptly addressed. Damaged steel props should not be used and should be either replaced or repaired to uphold the structural integrity and safety of the construction site. In conclusion, special storage and handling procedures are required for steel props to ensure their durability and safety. By adhering to proper storage techniques, employing careful handling practices, and conducting regular inspections, damage can be prevented and the quality of steel props can be maintained, ultimately contributing to a safe and efficient construction process.

- Q:Are steel props adjustable on sloping surfaces?

- Yes, steel props are adjustable on sloping surfaces. They can be extended or retracted to accommodate the specific height or angle of the slope, providing stability and support in construction or temporary shoring applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Prop & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords