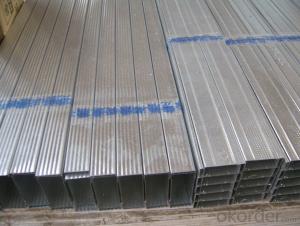

Steel Profile 60*27mm and 28*27mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Galvanized Steel Sheet

Application: Drywall ceiling and partition system

Size: different items / series for different markets

Thickness: 0.40~1mm

Length: Normal 3m/piece, can be customized

Zinc coated: Normal 40~50g/m2, can be customized

Function: Fireproof, Waterproof, Rustproof

Packaging Detail: in bundle, then into containers

Advantages and features:

1. Light, good strength, cauterization resistance and water resistance;

2. Matching different kinds of wall boards, such as gypsum board, fiber cement board, magnesium oxied board;

3. Moisture-proof, shock-resistance, high-effecient, environmentally-friendly and so on;

4. Easy and fast for installation, time-saving;

5. Prompt delivery, high quality, competitive price and complete sets of style;

6. Can supply products based on specific requirements;

- Q:Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Package workers a square meter twenty yuan or so, Bao Gong Bao material will be about a square meter 70 yuan,

- Q:Is in accordance with the vice keel 400, the main dragon spacing 600 spacing arrangement?

- There is no specific identification of the main and vice keel, can be carried out by standard or routine. According to the mechanical and aesthetic point of view should be said to you in turn, that is, vice keel and vice keel spacing 600, the main keel and the main keel spacing 400 arranged as well.

- Q:Will the light steel keel ceiling area is small can be no boom?

- But if there is no boom, then a long time there is danger, after all, the main force of the ceiling keel is the boom.

- Q:Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- Under normal circumstances about 30cm on it.

- Q:Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

- Q:What kind of size of the ceiling?

- Light steel keel wall materials are 50, 75, 100, 150 and several other

- Q:I am a novice . The How the keel is fixed on the ceiling of the hairy house. The Also gypsum board ceiling gypsum board is how to install on the keel I think: it will not fall? Is it to take nails or what glue up? What is the use of the boom (the ceiling will seem to use ..)

- There are standard hanging with the nails, fixed on the keel, will not fall, Of course, this is also a construction standard, not the same shed with the material will be different.

- Q:Play light steel keel cut off how not to damage the ceiling

- If the existing ceiling is gypsum board, there must be keel in the top

- Q:Light steel keel gypsum board ceiling is good, or sauna board, integrated ceiling buckle board good?

- Cost, gypsum board hanging flat top cheap! Performance is the best integrated buckle ceiling! Deformation coefficient is small! But the bedroom is no water! Suggestions or use light steel keel to hang! When loading the lights to hang on the keel! Light steel keel gypsum board ceiling about 70 per square meter it!

- Q:Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The difference is simple, Use the wood to do keel cheap, but not strong; with Cyclobalanopsis keel firm, really expensive. In fact, the wood is not so strong. Qinggang keel is also not where you go.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Profile 60*27mm and 28*27mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords