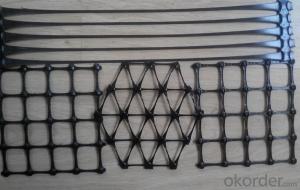

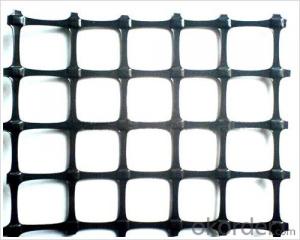

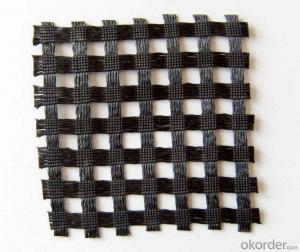

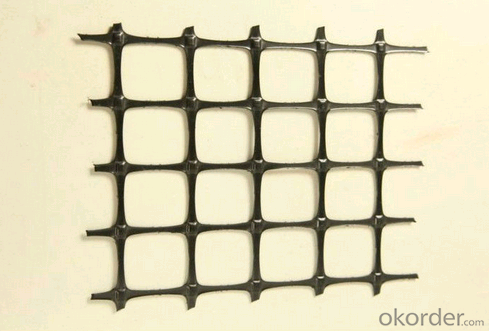

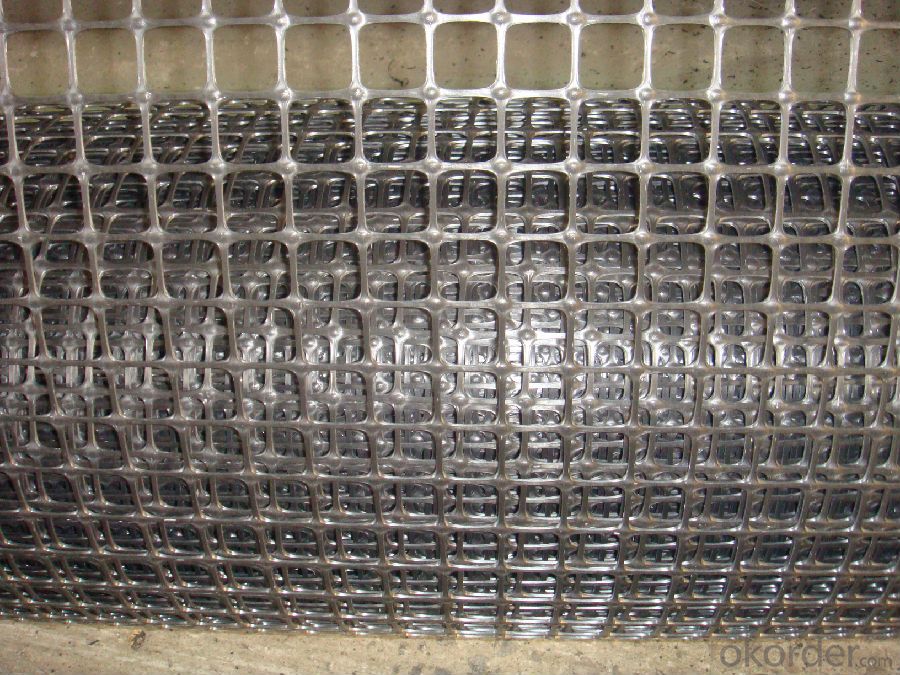

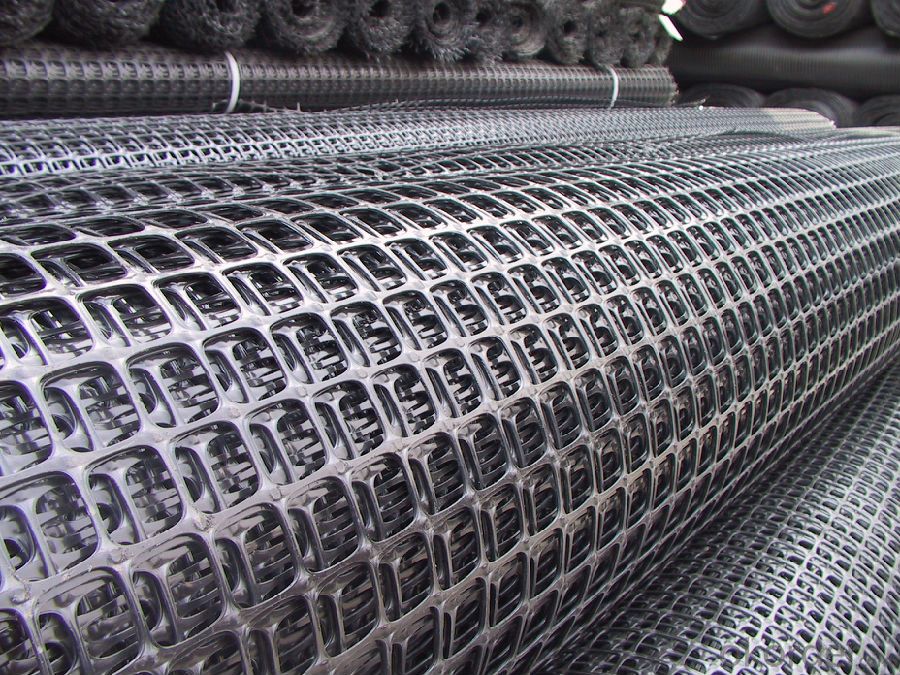

Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q:Can geogrids be used in mechanically stabilized earth walls?

- Yes, geogrids can be used in mechanically stabilized earth walls. Geogrids are commonly used as reinforcements in mechanically stabilized earth walls to improve their stability and strength. They effectively distribute the forces within the soil and reduce potential wall failure.

- Q:meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- The use of geogrid is simply to the road with a layer of nerve, connecting roads, extend the life of the road, to enhance the anti pressure of the road, on the road slope with geogrid is to maintain water and soil, has a fixed, but the way you say is permeable to water the road, plus the geogrid is add a layer of insurance, geogrid is here, ha ha

- Q:What is the road geogrid

- brief introductionGeogrid: GeogridGeogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosyntheticsGeogrid is often used as reinforcement of reinforced soil structure or composite materialGeogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid

- Q:How do geogrids improve the load-bearing capacity of foundations?

- Geogrids improve the load-bearing capacity of foundations by providing reinforcement and stability to the soil. These geosynthetic materials are placed within the soil layers and their interlocking geometry creates a more rigid and compact structure. This helps distribute the load evenly across a wider area, reducing the risk of settlement and increasing the overall strength of the foundation.

- Q:What are the advantages of using geogrids in ground improvement for seismic stability?

- Using geogrids in ground improvement for seismic stability offers several advantages. Firstly, geogrids enhance the strength and stability of the soil by providing reinforcement. They distribute the applied loads more evenly, reducing the potential for soil settlement and minimizing the risk of ground failure during seismic events. Secondly, geogrids improve the overall bearing capacity of the soil. By confining and interlocking with the soil particles, they increase the shear resistance and prevent excessive lateral movement of the soil, thus enhancing the stability of the ground. Furthermore, geogrids act as a barrier against soil erosion and prevent the loss of soil particles during earthquakes. They help maintain the integrity of the soil structure, reducing the potential for landslides and slope failures. Moreover, geogrids are flexible and adaptable, making them suitable for a variety of ground conditions. They can be easily installed and customized to fit the specific project requirements, allowing for efficient and cost-effective ground improvement solutions. Overall, the use of geogrids in ground improvement for seismic stability offers significant advantages, including enhanced soil strength, improved bearing capacity, erosion control, and adaptability, ultimately resulting in a safer and more stable foundation for structures in earthquake-prone areas.

- Q:Are geogrids suitable for reinforcement of mechanically stabilized aggregate layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate layers. Geogrids are designed to enhance the load-bearing capacity and stability of soil or aggregate layers. They can effectively distribute and transmit load forces, improving the overall performance and longevity of mechanically stabilized aggregate layers.

- Q:What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials, typically made from polymer materials such as polyethylene or polypropylene, that are used in civil engineering and construction projects. These materials possess several important properties and characteristics. Firstly, geogrids have high tensile strength, which allows them to effectively distribute loads and provide structural reinforcement to the soil. They also have excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various environmental conditions. Geogrids are lightweight, flexible, and easy to handle, making installation and transportation more convenient. Additionally, these materials exhibit low elongation and creep characteristics, ensuring long-term stability and performance. Overall, geogrids offer superior soil stabilization, erosion control, and reinforcement properties, making them valuable in a wide range of geotechnical and construction projects.

- Q:Construction technology of steel plastic grille

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.(5) as the second layer of geogrid layer construction method with the first method, and finally filling in 0.3m (coarse sand), filling in the same way as the first layer, using 25T hydrostatic roller two times, so subgrade reinforcement is dealt with.

- Q:Which is better than geotextile and geogrid

- The strength of the geogrid is much larger than that of geotextile, but the effect of geotextile on the road to prevent reflection crack is obviously stronger than that of Geogrid

- Q:Who has the "highway geosynthetics geogrid" specification

- JT/T925.1 2017 highway engineering geosynthetics

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords