Steel Plastic Geogrid Used in Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

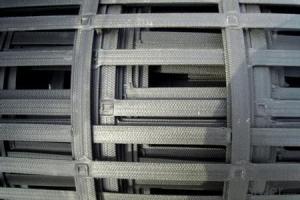

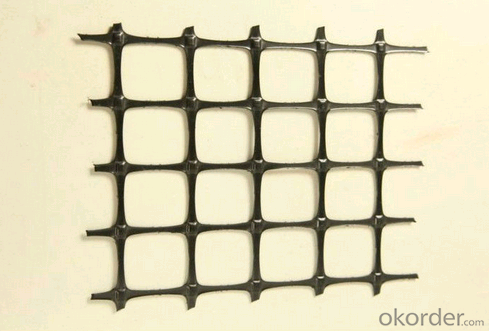

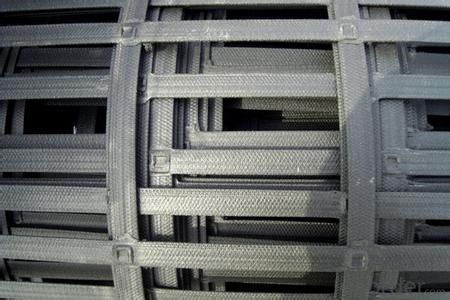

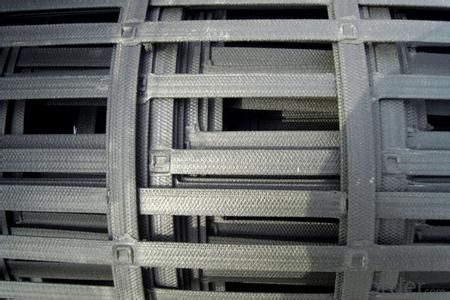

Black 100% new raw material steel plastic geogrid

suppliers from china

Description

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

Application

Make reinforcement treatment for varions kinds of sot soil foundation and strengthen shearing resistance of the soil body,used in reinforcement of retaining wall and widening of old road.

It is also used as protect-support net in the coal mine when layer mining of thick (coal) seam, and support of road way in the coal mine.

Specification

| Specifications | GSZ30- 30 | GSZ40-40 | GSZ50-50 | GSZ60-60 | GSZ80-80 | GSZ100- 100 | GSZ150-150 |

| Tensile Strength KN/m(LD) | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Tensile Strength KN/m(TD) | ≥30 | ≥40 | ≥50 | ≥60 | ≥80 | ≥100 | ≥150 |

| Elongation Rate(LD TD) | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| Tensile Strength at 1% Elongation Rate(LD) | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Tensile Strength at 1% Elongation Rate(TD) | ≥20 | ≥32 | ≥40 | ≥48 | ≥63 | ≥81 | ≥125 |

| Limit PeelForce at Welded Bonded Point N | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 |

| Products in the range of coal mine | Fire out time from outer flam | ≤3 | |||||

| Surface resistivity | <1×109< span=""> | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

1. How about the delivery time?

Lead time since receipt of 30% T/T deposit payment: 3 weeks.

2. What kind of payments does jenor support?

T/T, L/C, Cash are accepted.

3. What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

5. Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6. Can you tell me your main customers?

That's our customers' privacy, we should protect their information. At the same time, please rest assured that your information is also safe here.

- Q:How are geogrids manufactured?

- Geogrids are manufactured by extruding or weaving polymer materials such as polypropylene or polyester into a grid-like structure. This process involves melting the polymer, forming it into a grid pattern, and cooling it to create a strong and flexible geogrid.

- Q:Plastic grid plate making process

- The plastic grid plate is also called the civil grille also known as the geogrid is made of polypropylene, polyvinyl chloride and other high molecular polymer thermoplastic or molded from the two-dimensional mesh or with a certain degree of three-dimensional grid screen,

- Q:What are the names of geotextiles?

- Geotextile, also known as geotextile, is made of synthetic fibers through the needle or woven into the permeability of geosynthetics.

- Q:How much is the double polypropylene plastic geogrid outsourcing testing fee?

- Detection parameters, the price is not the same

- Q:What is the number of tensile elements of Geotextiles

- The number of tensile units in the test is the number of holes or the number of squares in the width of the test. For example, geotechnical geogrid 1m width of 25 holes, stretching the number of units is 25, the width of the sample is 200mm with a hole of 5, the number of tensile units of the sample is, C=Nm/Ns c=25/5=5 personal understanding is not necessarily more than

- Q:Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

- Q:How do geogrids affect soil compaction?

- Geogrids help to improve soil compaction by providing reinforcement and stability to the soil. They distribute the load more evenly, reducing the risk of settlement and improving overall soil strength. Additionally, geogrids enhance the interlocking behavior of soil particles, increasing the soil's resistance to shear forces and minimizing lateral movement.

- Q:Can geogrids be used in subgrade stabilization?

- Yes, geogrids can be used in subgrade stabilization. Geogrids are commonly used in civil engineering projects to reinforce and stabilize weak or poor subgrade soils. They provide additional strength, distribute loads more evenly, and help prevent soil erosion.

- Q:How do geogrids improve the performance of geosynthetic-reinforced retaining walls?

- Geogrids improve the performance of geosynthetic-reinforced retaining walls by adding stability and enhancing the overall strength of the structure. They function by distributing applied forces throughout the wall, reducing pressure on the wall face, and preventing soil movement and potential failure. Geogrids increase the bearing capacity of the soil, improve the load-bearing capabilities of the wall, and provide long-term reinforcement, making the retaining wall more durable and resistant to external forces.

- Q:What are the limitations of geogrids?

- Geogrids have a few limitations. Firstly, they are not suitable for all types of soil and terrain conditions. They are most effective in soils with good particle interlock and cohesion. Secondly, geogrids are not effective in situations where there is high water flow or erosion potential as they do not provide sufficient protection against these forces. Additionally, geogrids may have limited strength in certain applications, such as heavy load-bearing scenarios, and may require additional reinforcement. Lastly, the installation and maintenance of geogrids can be complex and costly, requiring skilled labor and regular inspections to ensure proper functioning.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Plastic Geogrid Used in Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords