Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

Features standards and products of our butt welding fittings:

Features of Butt-Welding Reducing Outlet Tees:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Reducing Outlet Tees:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Reducing Outlet Tees:

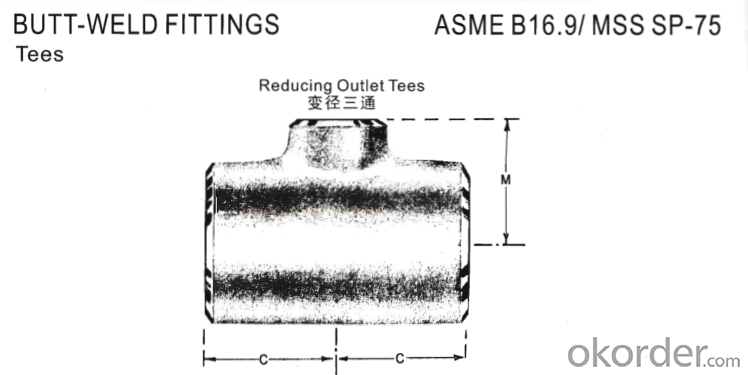

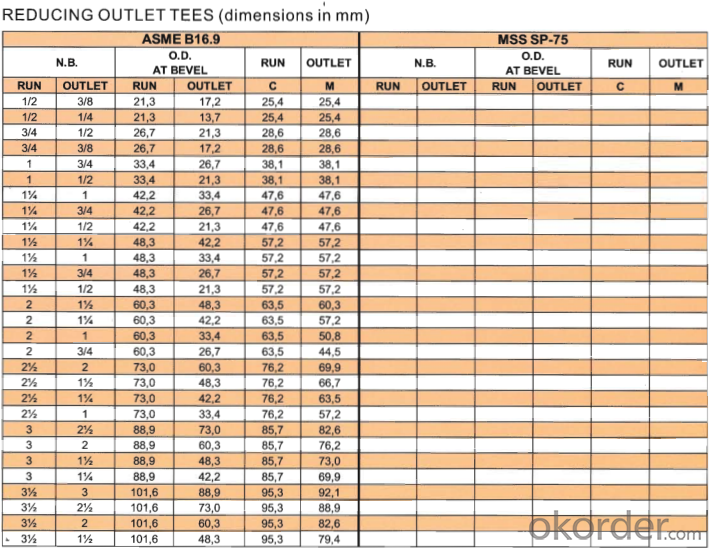

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Reducing Outlet Tees:

Packing of Butt-Welding Reducing Outlet Tees:

FAQ of Butt-Welding Reducing Outlet Tees:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:my grandma's dog is afraid of smoke detectors and wont stop panting and shaking. he is constantly under her feet. he is even afraid if he hears it on television

- its a bit odd but im sure she will bag up soon!

- Q:I want to run an electric blanket in my shed during the winter to keep the outdoor cats warm. Would this be a fire hazard?

- I think she's just asking for it.

- Q:isnt a body of water (pool) attract lightning? but if it is an underground pool, with a child in it, wouldnt the lighting go into the ground, and not harm the child???

- I would have to say.you thoroughly confused me. If there was a fire, what difference would it make who pulled the alarm and what does aspergers have to do with it? Most kids with aspergers are very high functioning, so I'm not sure exactly what the question is. If an 11 year old sees a fire that is out of control, then there should be no problem with that child pulling the alarm. Period.

- Q:What are the standard drawing numbers for hydraulic couplings?

- The ends of the pipe shall be flush. The pipe should be flush in sawing grinding wheel and other tools, and burr cleaning and blowing with high pressure air before use.When installing, the coaxiality of pipe and joint body should be kept as far as possible. If the pipe deflection is too large, it will cause sealing failure.If the pre loading force is unfavorable, the inner edge of the ambassador card sleeve is just inserted into the outer wall of the pipe, and the clamping sleeve should not be deformed obviously. When the pipeline connection, and then according to the specified tightening force assembly. Phi 6-1 card sleeve tightening force is 64-1 15N, 16 MMR 259n, Phi Phi 18mm for 450n. If the sleeve is badly deformed at pre assembly, it will lose its sealing effect.

- Q:What type of material will reflect most of the electromagnetic waves coming from a microwave magnetron? What kind of material is the best?

- Maybelline /index?desktop_uri%2F/watch?v8w-B-_7q6NI

- Q:i have the axles of butt dont wont to break eneything

- If it is your intention to join 1/2 pipe to 15mm copper pipe then use a compression type fitting NOT a solder type fitting, as most people have indiocated, there can be slight differences OR with older type 1/2 copper pipe Quite large differences, so always use compression ( the ones that require an olive, and have to be tightened with a wrench ) Wrap plumbers tape around the olive, and don't overtighten.

- Q:May I ask what material EN39 is? Used to make a threaded pipe joint

- It specifies the material and tolerance requirements of the steel pipe. From the material point of view, the steel in the EN39 standard is similar to that of China's Q235B.

- Q:I wear a lot of foundation with powder on top all over my face. I know this seems like a really really stupid question, but i'm incredibly self-concious about it. Is there any way that I can stop my safety goggles from ruining my makeup? I have chem first period and dont really have time to go to the bathroom in between periods. Putting on mkeup during class, or wearing less makeup is out of the question. PLEASE HELP this is really important to me

- There should be a bill of material to go with that drawing that defines what HV-170 means. Some designers number each valve or special component in a piping system for inventory purposes. These are typically listed in a bill of materials.

- Q:Hi there..I'm a gap year student going off for volunteer work in Luang Prabang, Laos in November. Since it is hard to find many details on the internet, I thought I'd try here :)I would just like to know the basic conditions and things to be aware of, especially regarding safety in travelling alone (I'm an 18 year old girl and I look like I'm 12 :S ) Is it ok to visit the shops and walk around by myself? Also, are there any concerns about clothing, as in are there restrictions on what is appropriate.Since the organisation I'm volunteering for, pay for my meals and accomodation, I was wondering what would be a reasonable amount to have as spending money. As in how much would I need per month, for getting around, buying souvenirs, extra food, visiting attractions, etc.Thanks everyone!

- Yes I have, I haven't found anything worth mentioning though but I always get the strangest feeling that there is something out there waiting to be found.

- Q:I am making a story book for children and I want some ideas of things that can burn in fire I have some in mind but looking for some ideas thank you

- If you are trying to fix a leak in copper water pipes, (say they froze and split, or leaking at bad solder joint, etc) the best thing to do cut out the bad part and re-solder new pipe/fittings as necessary. If it is just one tiny pin-hole and it is in a place where it would be really hard to re-solder, they do have these metal clamp-like cuff things that mash a piece of rubber sheeting over the hole.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords