Steel Pipe Fittings Butt-Welding Reducing Outlet Tees High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

Features standards and products of our butt welding fittings:

Features of Butt-Welding Reducing Outlet Tees:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Reducing Outlet Tees:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Reducing Outlet Tees:

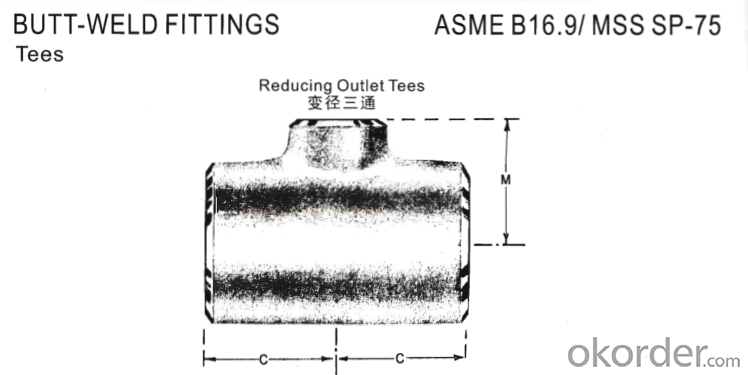

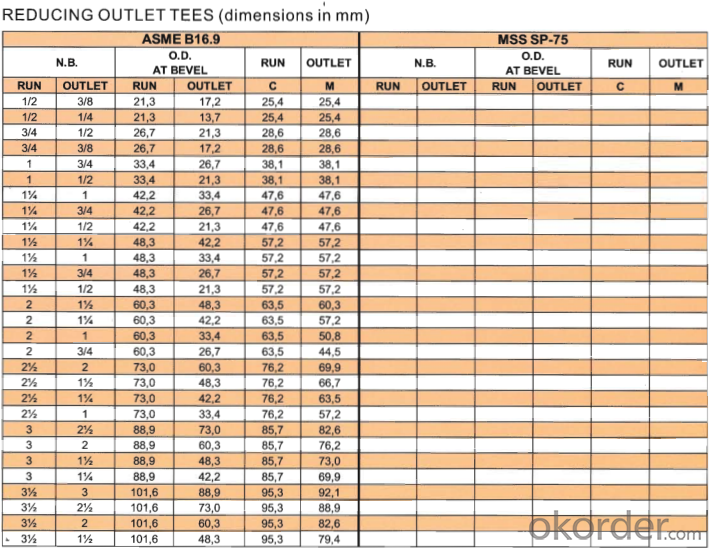

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Reducing Outlet Tees:

Packing of Butt-Welding Reducing Outlet Tees:

FAQ of Butt-Welding Reducing Outlet Tees:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Requirements for fire hose fittings

- (2) galvanized steel pipe with diameter > 100mm of hydrant water supply system shall be flanged or grooved. The automatic sprinkler system, 100mm diameter is not clear thread connection cannot be used in pipe diameter greater than 100mm shall be provided with flange connection or groove connection point at a distance only.(3) the water supply system of fire hydrant water supply system and automatic sprinkler system shall be threaded flange, and two zinc plating shall be adopted when welding flange is adopted.

- Q:I don't know which color to choose. The walls in our living room a a light cream color and we have wood floors.that are a medium brown. We have wood furniture. We will have a baby and that's why we're choosing leather - easier to clean. Which color do you this it's best given this details?Thanks!

- All metals are perfect reflectors of electromagnetic radiation. Your suggestion of aluminium foil is a good one but it needs to be perfectly smooth with no wrinkles or creases and I imagine that might be quite difficult to achieve.

- Q:Is the pipe seat a pipe joint or a standard connection?

- The branch pipe seat is divided into six types: butt welding supporting seat, socket pipe seat, seat, seat tube thread pipe branch, branch, branch pipe seat seat mitered elbowThe domestic standard for manufacturing standards is GB/T 19326

- Q:At times there are guys i find attractive that i'd like to approach but i find myself unsure if they want to be approached at all. I know some attractive guys get harassed a lot so they often keep a really stern or almost angry looking face. Is that shield up for them? Also i am not a super model ever so hot person, i think i am pretty average and normal looking, and i have seen some attractive guys get offended when 'normal' people approach them, I know all guys are not like this, but is there a way to tell if he just rather not be disturbed by me?

- Snow Bowl toilet bowl cleaner will make them look like new. I don't about other brands. I always used Snow Bowl. I use it to restore old brass soda acid fire extinguishers.

- Q:is sleeping with a heating blanket every night save?

- pain counsiler the tamer (pick them up on ur shoulders like the f-u but there back facing the other way you flip em and a ddt at the same time

- Q:What's the half pipe connection?

- The half pipe connection essentially means that the branch pipe becomes larger when it is connected to the main pipe through the half pipe joint

- Q:Let's say you're on 3rd gear and there's a speed bump or a pedestrian crossing ahead and you have to slow down. Do you have to shift to a lower gear or can you just slightly press the clutch and the and the break?Also, it it possible to go from 1st gear straight to 4th, skipping 2nd and 3rd? Or do you have to change to each one at a time?

- I've never heard of such a thing, but there probably is! Otherwise, you could get a job as a photographer for a newspaper, and take pictures of not just fires and stuff, but other large, local events!

- Q:I know about the tent and sleeping bags. But for fire and food and going to the bathroom etc

- yes it is cause it keeps your hands safe i am a nursing assiant and i have to gloves all the time

- Q:Many of the shareholders dislike with current coop board member. They (current board) know that they will lose in the coming election, so they decided to count votes in a different room, away from shareholders' view. I mean this is stupid , even kids know how to cheat in this case. ANYONE can help us? We already have ppl who r willing to replace current board and we sure that we have more than 50 % of shareholders supports the new board. However, nothing mattersIf they are going to cheat in the counting process..This is sad. I am so disappointed something like this is happening on the United States of Amercia ! Some of u might be thinking hiring a lawyer but we think of it, too. We don't think hiring a lawyer would work since current board is still in charge, they can make the rules as long as they are still in chargethis is stupid..

- Yes. You should get a reduction in rent. They should have someone in to fix it in one day. This is an emergency.

- Q:How much is the monofilament of the 304 pipe joint?

- Small size is cheaper, and one more thing is the thread standard you want to connect to

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords