Steel Pipe Fittings Butt-Welding Equal Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process:

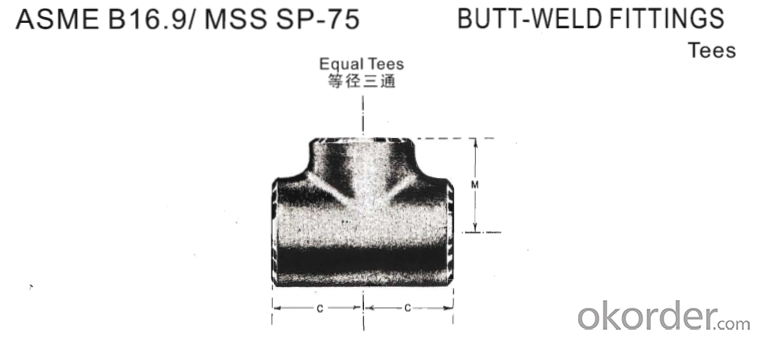

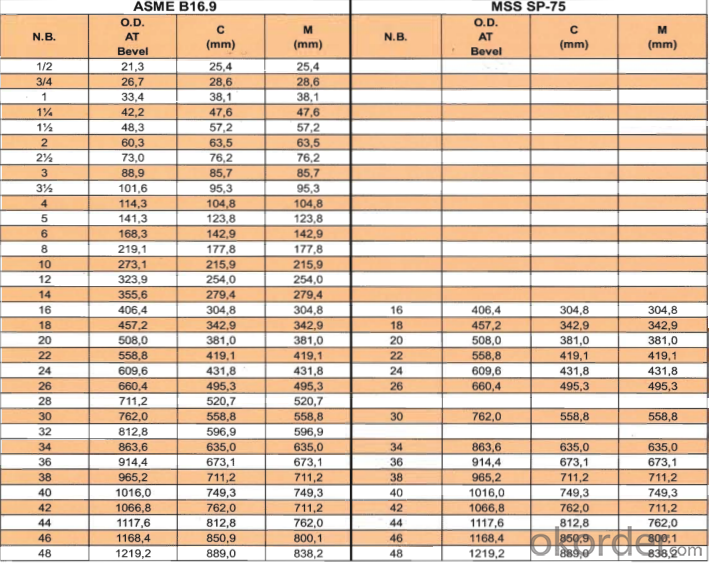

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Equal Tees:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:I keep seeing those movies where the killer has a car that is filled up with water on the inside and their victim is inside dead as if they were trapped inside the car and drown. But the car isn't submerged in a pool or lake it is as if the killer put a hose in it and drown them. Can it be so simply done or do you have to water seal your car get all fancy like that? Just the random thought of the day.

- The plumbing is usually only as good as the plumber's work. I've used both pex and PVC and had equal success with both. Assuming we are doing residential plumbing, and sticking with 1/2-3/4 pipe, I prefer pex and push on fittings at work because I can do the work very quickly plus I don't have to worry about drying time to put pressure on the lines. If I were going to do this work in my home, I'd definitely go with PVC because it's much cheaper. The trade off is time vs. money. If time is more precious, go with PEX, if cost is more of a factor, go with PVC. Obviously do your drain lines and stacks in PVC. PVC cement is more or less universal-just make sure you use cement meant for CPVC and PVC and use with PVC primer.

- Q:how do you clean your mouse etc.?

- I am an old hand at using hair rollers, the best ones are wire with a brush in the center and have a pick to hold them in, the pick goes in from back to front or the opposite of the way you roled your hair, wash your hair and put the rollers in so they are neat and not loose. You can sleep in them but not the most comfortable, no roller is. they give a great curl. you will then beable to just run your fingers through the curls and love the look.

- Q:What do you mean by the next connection in the pipe connection? How do you use it?

- The difference with the common joint is that the thread on one side is longer, and the next joint is fixed to the board by the locking nut

- Q:Hello. I ve recently used a gas mask to go into a asbestos ridden area. However my clothes have been contaminated and so has my mask. How would I go about cleaning them safely? My mask and all clothes are in a garbage bag currently waiting. I am a college student so would prefer a cheap method to clean my clothes (most importantly my mask). Do I need to bring them to someplace special or can I do it safety at home? Am I safe to use the mask again if I remove the dust outside wearing another mask? If I were to enter the area again should I just use contaminated clothes? Help please!

- Replace the door latch and check the alignment of the door hinges, depending on usage the hinge bushings wear causing the door to sag or drop low. This also prevents the door from latching properly. Could also try lubricating the latch assemby in the door (should be done on a regular basis with oil change maintanence)

- Q:I'm a guy and need some damn good reliable clothes for work.so boots : any suggested sites to buy from (military (must be actual military! or safety boots brand?)Trousers need good work trousers tough and comfy! (not the crappy 'pretend style jeans')Shirts must be comfy and breathable t shirts the sort that do not shrink to x small (I am aprox L xL but xxl is good too)so brands and/or sites and please non of the 'lets pretend to make clothes and call it army/tough workmanclothes' you know the sorts, they are everwhere and get on my rugged hairy man **** .

- I don't really understand the purpose of a one piece in a theme park but ok. For safety reasons it doesn't make sense. I would say go with a comfortable bra (swimsuit) that wouldn't undo easily and simple bottom swimsuit. Just wear whatever you want over it as long as you stay with pants. If you have to wear a one piece just choose a flowy top that covers it. I would suggest you to take another pair of shorts and underwear with you so you don't get cold.

- Q:I have a heat detector and alarm (

- A street elbow is a type of plumbing or piping fitting intended to join a piece of pipe and another fitting at an angle. The difference between a street elbow and a regular elbow is the nature of the fittings on either end. A regular elbow has hub or FIP on both ends. A hub is a female ABS, PVC or copper pipe receiver; FIP denotes Female Iron Pipe threads, that is, it receives threaded MIP iron, brass or plastic pipe on both ends. FIP is also known as FPT, Female Pipe Thread, and MIP denotes MPT Male Pipe Thread. Generically, these are known as NPT fittings (National Pipe Thread fittings). A street elbow has a female fitting (hub or FIP) on one side and a male pipe or MIP fitting on the other end. The advantage of the street elbow is that it can be connected directly to another fitting without having to use a short connecting piece called a pipe nipple. Street elbows are available in 90°, 45° and 22.5° bends. They can be used in water supply, drainage, sewer vents, central vacuum systems, compressed air and gas lines, HVAC, sump pump drains, and any location where plumbing fittings would be used to join sections of pipe.

- Q:The same is PVC material, one called PVC connector, one to PVC pipe joint, what's the difference?

- Two, plastic pipe type 1, PVC (PVC-U) plastic wire pipe (hard tube), 2 and PE threading pipe (winding hose) 3, plastic bellows (flame retardant bellows, wire harness casing, high density bellows, high temperature protective casing, etc.)Three. Ceramic tube 1, threading porcelain bushing 2, glass fiber woven insulating sleeve

- Q:PT3/4 what is the diameter of the pipe joint?

- 1. thread sealed pipe threads, without padding or sealing, can prevent leakage. The pipe thread with screw thread has two connecting forms: cylindrical internal thread and tapered outer thread, tapered inner thread and tapered outer thread. When the pressure is below 5 * 105Pa, the former connection is close enough, and the latter connection is usually used only at high temperature and high pressure.

- Q:I should be the system administator for my home personal desktop computer. Why can't I access files etc. that I did not enter into my computer? Thanks for your help!

- That's why we have video games like Call of Duty and Killzone 2.

- Q:If you could think of one it would be much appreciatedthanks

- it would want to easily be dirty and in favor of a reliable cleansing attempt cleansing the paper sensor and rollers The sensor might want to be placed with suggestions from beginning the front hide the position the ink cartridges are. even as searching interior in basic terms to the right of center manually feed a piece of paper like the printer does immediately. you're able to see a skinny black lever flow up and down as you push the paper in and pull it out again and again. it truly is the paper jam sensor. ANY overseas merchandise contained in the way of this sensor will reason a three orange effortless flash indicating a paper jam. Very puzzling to locate without a flashlight. yet another reliable concept may be to blow out the printer utilising a can of compressed air. sparkling both Rollers gently hose down your lint-loose cloth with water or alcohol. Squeeze it out to verify that that's no longer too moist. carry the cloth in a unmarried hand and press it gently hostile to the first roller. which includes your different hand, gently rotate the roller until eventually you've wiped clean all of it the way round. Be quite careful. do no longer use too a lot rigidity. you've were given to run it with the aid of a few cases to get rid of all the residue

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Equal Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords