Steel Pipe Fittings Butt-Welding Concentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Concentric reducers

Features standards and products of our Butt-Welding Concentric reducers:

Features of Butt-Welding Concentric reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Concentric reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Concentric reducers:

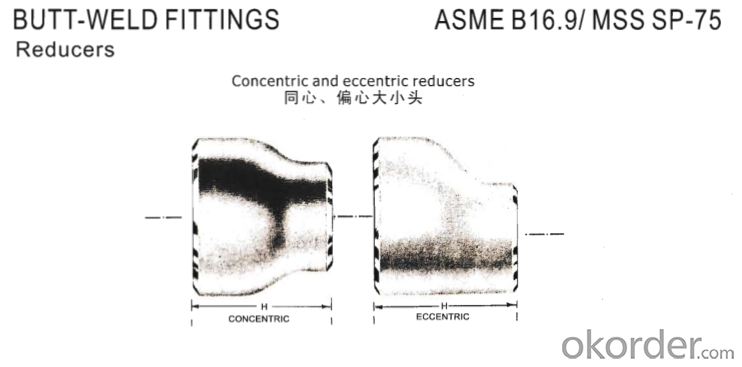

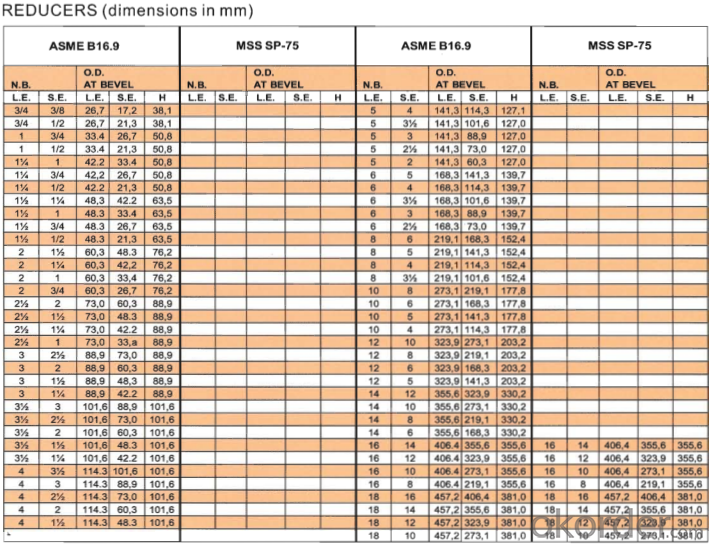

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Concentric reducers:

Packing of Butt-Welding Concentric reducers:

FAQ of Butt-Welding Concentric reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:something odd, yet makes sense. oil sponge, ocean speed bump, future jacket. stuff like that.)

- A gift certificate.Can't go wrong.

- Q:I would like to know where to find on the Web a bicycle helmet either with a built-in face shield (covering the actual eyes and face, not just a peak like the brim of a baseball cap), or a separate face shield that you can attach to a helmet to cover your eyes and face.Try not to limit your focus to visors on the time trial style bicycle helmets. No references to motorcycle-only helmets please! I am referring to bicycle helmets.Please link to pictures!

- Tough situation; the easy thing to do would be to let it go since you're about to leave. The right thing to do is to police up your battle buddy. You've been in long enough to know that if your battle buddy gets caught sleeping, he won't be the only one in trouble. So? 1. Tell him he's a turd and doing the wrong thing. 2. If he doesn't correct his actions, notify the NCO on duty. Impede his every attempt to be a dirt bag. Turn the fan back on. If he wants to argue about it, let him get loud. When the NCO comes in, make no quams about saying My battle buddy is upset because he wanted to sleep so he turned the fan off to hear you coming. The threat of turning him in should be enough to correct his behavior, if only for the short term. And that's all you have to deal with him for. Or notify your Student Team Leader, Squad Leader, Platoon Sergeant, etc. Work it up your student chain of command and give them the opportunity to help you.

- Q:My stepson is 18 a junior in high school. (Held back a year in elementary school - for social, not academic, reasons). According to his mother he was diagnosed with severe adhd at age 2. They didn't treat it with medication. nothing. nada. Now he is living with us and he is my problem. He does not have a job, 'forgets' to do the very few chores we give him (yes, we even have a chore chart for him to use), he is sullen and mouthy to his father (nice to me, though), and he has no direction in his life. He wants to go to school in Canada and become a video game designer. But he isn't the least bit concerned about taking the SAT, getting good grades, having extracurricular activities, etc Just last night he left the freezer door open and ruined hundreds of $$ worth of food. He has finally stopped eating in the den and leaving food everywhere (that only took a YEAR to get him to do) and his father thinks that's enough. I disagree. HELP?

- Well maybe you could offer to clean his car for him..I know id love my gf to get my car nice and clean/washed. You could get him a gift card to a local audio store, ummm you said speakers but does that include like subs and an amp? If he doesnt have those maybe he be interested in those. or maybe a gas card if he has to pay for his gas

- Q:can i set an alarm for a 1st gen ipod nano and if so how? please help

- Condoms, Brooke Shields, Dettol and Pig Destroyer Just a thought, like

- Q:I think OSHA would require safety goggles around those things..

- There is an easy way to tell they're a crap breeder that's only in it for the money. That ad screams it. Personally, I wouldn't have given that ad a second look, especially with the potential health issues CKCS are prone to. I'd want a well bred one. If you're set on the BYBd dog though, when you show up to the house to pick up the puppy it should be relatively evident if it's a puppy mill or not. If they do not want you to meet at the house, it's typically a puppy mill as well.

- Q:Is there a flawless way to access myspace from school? ive tried everything!?

- fittings permit a change in direction of piping, a change in diameter of pipe , or a branch to made from the main run of pipe. like elbow , reducer , tee couplings and nipples are used in socket welded and threaded systems and they joint pipe to pipe , or to nipple swage , joint tow different diameter pipe an d some like that.

- Q:I'm a guy and need some damn good reliable clothes for work.so boots : any suggested sites to buy from (military (must be actual military! or safety boots brand?)Trousers need good work trousers tough and comfy! (not the crappy 'pretend style jeans')Shirts must be comfy and breathable t shirts the sort that do not shrink to x small (I am aprox L xL but xxl is good too)so brands and/or sites and please non of the 'lets pretend to make clothes and call it army/tough workmanclothes' you know the sorts, they are everwhere and get on my rugged hairy man **** .

- She / ) which is worth looking at.

- Q:The law requires everyone to have only liability.I also have comprehensive incase my car gets stolen.But i dont think a tree is going to fall on my car for me to get collision.If someone hits my car their liability insurance will fix it so what does collision do for me?I thought comprehensive covers me if i hit a fire hydrant..or it that what comprehensive is for if i hit a wall or run into something?

- the device you need is called a scald prevention valve. when the cold water volume drops it automatically reduces the hot water volume.

- Q:I'm buying my first motorcycle soon. I'm going to wear a full-face helmet. My question is, will a windshield on the bike do anything for me? The majority of my riding will be at 45 mph or less. Occasional highway at 60-65 mph, but only for 3-4 miles at a time. Thanks!

- On a hot compressor pipe no: It would melt and is not capable of withstanding the pulsating pressure. If you are repairing the pipes after the regulating valve then possibly.

- Q:A fire hose held near the ground shoots water at a speed of 6.7 m/s.At what angles should the nozzle point in order that the water land 2.0 m away?

- If you are dealing with Garden Hose Thread Fittings, which seal on a gasket they should be relatively easy to unscrew. UNLESS they are made of dissimilar metals and have been in contact long enough (many months) to develop Dielectric Corrosion effectively fusing the two together. If dielectric corrosion has occurred some discoloration (often White) will be seen between the threads, and it will take significant effort to break them free. That effort might damage or destroy the fitting, depending on the extent of the corrosion. My suggestion is to get some Liquid Wrench or other Penetrating Thread Lubricant, and follow the directions to free up the connection prior to applying extensive pressure or torque. A Strap Wrench is often used to tighten round pipes where damage to the pipe is not an option. The Leather Strap wraps around the pipe providing virtual 360 degree contact. A Chain Wrench would provide more positive grip, but is more likely to do damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Concentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords