Steel Pipe Fittings Butt-Welding Concentric Reducers High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Concentric reducers

Features standards and products of our Butt-Welding Concentric reducers:

Features of Butt-Welding Concentric reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Concentric reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Concentric reducers:

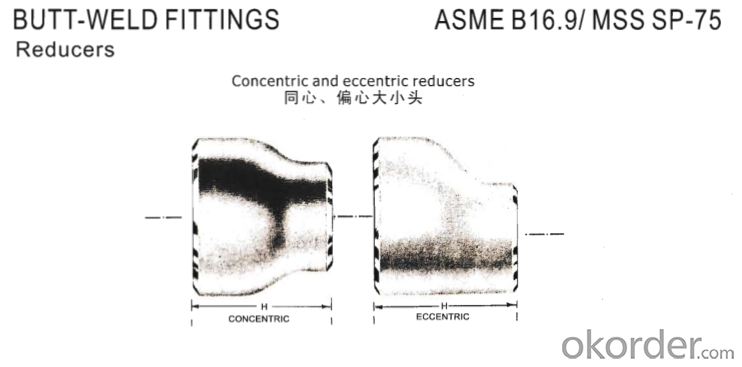

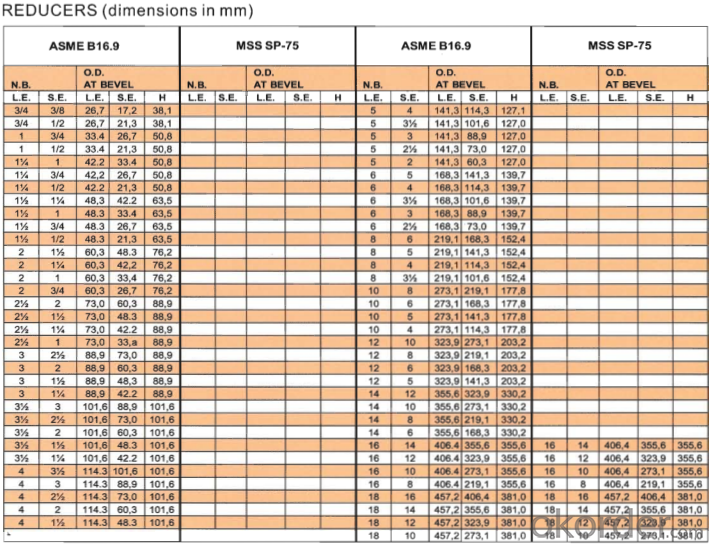

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Concentric reducers:

Packing of Butt-Welding Concentric reducers:

FAQ of Butt-Welding Concentric reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:I would like to ask who has 24 degrees taper hydraulic pipe joint processing drawings, please send me, thank you very much

- To use their own drawings approved by the good deeds since then, almost no tiny bit. PM me when needed ~!

- Q:how can the sun breathe in spacei f astronauts need suits

- Most of my lifestyles has been in Musical Theater. My youngest daughter on the second, is in Chorus Line. We party each 12 months, regardless of wherein we're, and appear on the Tony's in combination. There is not anything adore it. Funny Girl, Mame, Hello Dolly, Joseph and the Technicol Dreamcoat, Les Miserable - one would move on and on. When we went to peer Mama Mia, the film, it was once a extraordinary revel in. For the primary time in a film Theatre the complete viewers took facet. They stood up and sang, danced and we had been all a facet of the film. Music, personally, is without doubt one of the benefits which have been bestowed on Human Beings. My lifestyles might no longer be what it's, or has been, if it was once no longer for track and Musical Theatre, on movie or on level.

- Q:Beauty stuffClothingSafetyStuff for funanything! :]

- As I am a spiritual person and really don't believe in popular christian beliefs, I'd say that lightning rods are put in place for the proper discharge of lightning strikes to a building or object. The rods either go all the way down to the ground or have a copper wire that goes down. This allows a path of least resistance for the lightning to discharge into ground.

- Q:What kind of tubing connections do you have?.

- According to the number and direction of the connection, there are straight through, right angle, three pass and other types. The connection with the body has threaded connection, flange connection and so on. In addition, there are some special purpose pipe couplings.

- Q:I also want to know if I can put some kind of 'tinting' that is metal based over the windows, and if I would need to ground the RV and put a lightning rod up. I assume a NEMP would fry a simple line filter, how can I do the metal lines, or the water supply? For an option on the windows am considering metal screens, grounded to body. Perhaps double layered?

- difficult point. browse over a search engine. it could actually help!

- Q:My computer running XP as made my control panel just dissapear. I tried going to run and typing control.exe and it says This operation has been cancelled due to restrictions in effect on this computer. Please contact your system administrator. I am the adminitrator!!!! I have Windows one care and it also keeps popping up with trojans that I tell it to clear all. Then it says successfully removed then pops right back up with the same trojan detected??? What gives?? I contacted Microsoft and waiting for a response. Any help would be awesome thank you.

- Use PVC reducers and/or bushings to get from the larger pipe to 1/2. Get a can of primer to use with the PVC cement (first clean the pipe fittings w/ primer, then glue).

- Q:Land lord now. We have nasty old singe pane windows. Can we request to replace them with double pane windows and would it resolve the mold issue?

- Typically, no. The fog that comes from dry ice IS NOT smoke. It is water vapor. But it ALSO contains a lot of carbon dioxide, so if your smoke detector is of the CO 2 type, then yes.

- Q:proxy for myspace that can bypass web senses?

- Dude, you've learned too much. Get some good night sleep, wake up the next day and have a fine cup of cappuccino. That ought to deal with this. MAN !!!!! ARE YOU OUTTA YER MIND ??? Well, curiosity's good, but NO.

- Q:So not too long ago, I was watching the people in the kitchen at Carl's Jr making the food. I noticed they were using their bare hands. I thought they were supposed to be wearing gloves?

- It started about 5000 years ago. No, that is not a typo. From the copper development association, The craftsmen who built the great pyramid for the Egyptian Pharaoh Cheops fashioned copper pipe to convey water to the royal bath. That was indeed, over 5000 years ago. It was at the end of the 1920s that copper was first introduced in the U.S. as supply pipeing, and before that cast iron had replaced the very first systems which were wood. Yup, wood. From comes this little tidbit - In old construction, lead plumbing was common. It was generally eclipsed toward the end of the 1800s by galvanized iron water pipes which were attached with threaded pipe fittings. Higher durability, and cost, systems were made with brass pipe and fittings. Copper with soldered fittings became popular around 1950, though it had been used as early as 1900. Plastic supply pipes have become increasingly common since about 1970, with a variety of materials and fittings employed, however plastic water pipes do not keep water as clean as copper and brass piping does. Copper pipe plumbing is bacteriostatic. This means that bacteria can't grow in the copper pipes. Plumbing codes define which materials may be used, and all materials must be proven by ASTM, UL, and/or NFPA testing. So it isn't exactly clear when each type was first introduced as many different types overlaped each other, but in general, and concidering *modern* as being after 1900, galvanized was probably more frequently used than copper, even though copper goes back much further. Al

- Q:I'm doing a project where you get a shoebox and put it under sunlight or a heat lamp. What materials can I put in the box to make it heat up faster? Mainly materials I can find at home and don't have to go out and get. Also will keeping the lid on the box help it heat up faster?

- Pipe Fitting Take Offs

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding Concentric Reducers High Pressure

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords