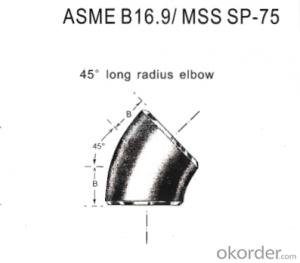

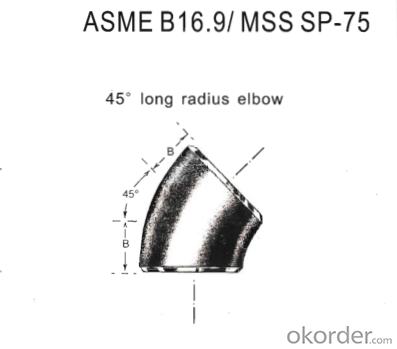

Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

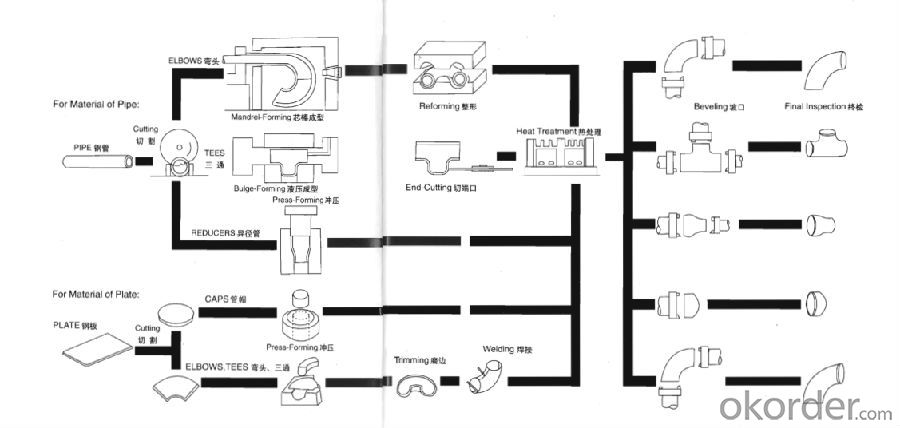

Manufacturing method and process:

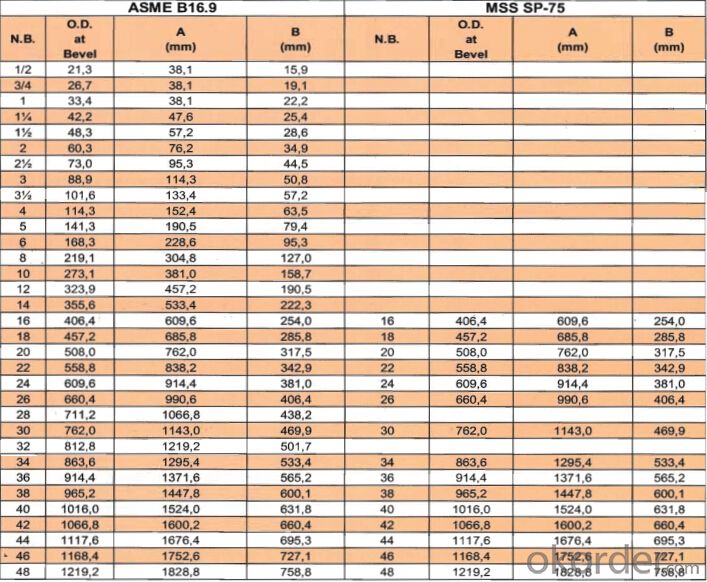

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

45° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:How to distinguish the type of tubing joint?

- Corresponding to the different pipe fittings, you should have a good look at the mechanical design manual

- Q:I would like to ask who has 24 degrees taper hydraulic pipe joint processing drawings, please send me, thank you very much

- To use their own drawings approved by the good deeds since then, almost no tiny bit. PM me when needed ~!

- Q:Which rod is best for light saltwater use?

- I think a key difference between necklaces and a metal rod is that the metal rod is on the inside of your body. In most cases electrical current flow is on the outside of a conductor. This is why people inside of cars and planes are usually unhurt by lighting strikes. The current flows through the outside metal body. Or, If you have ever seen a demonstration at an electrical show where someone stands inside of a cage and the cage is hit by electrical sparks and the person is fine, this is the same concept in action. Referring back to your original question, jewelry is on the outside of you body and is a good conductor and the current will from your body through it, and the electricity then has to flow back through your body to reach ground. There is resistance heating whenever the current has to flow into another medium. This is partly what melts the jewelry and causes the burns. What would happen with a metal rod is harder to guess and would depend alot on whether or not it was raining and your body was soaked, but it is unlikely that that a rod inside the body would have a large current flow through it. It would not be electrically advantages for the electricity to flow from the outside of your body to the inside. The longer the rod get the more likely it is that it would become the path of least resistance and possibly receive current flow. If there was current through the rod, the most severe burn would happen where the current entered the rod and left it.

- Q:Has anyone ran these tires before?How they work in snow/mud/ice/slush/off road?They are studdable so do i really have to have them studded? If I get them studded for the winter months, then in the spring is it possible to get the studs removed?

- No because you are not parked you are abandoning a burning vehicle which is legal no matter where you happen to be.

- Q:Okay, so I recently found out that I'm moving back to the US from south east Asia. My BFFaeaeaeae lives there and it's terrible being away from her! We see each other ever Christmas and Summer and practicality live at each other's houses when I'm home. She always asks when I'm moving back but since i never dreamed that it would happen before college, I've always told her that it's not going to happen.But,Now it is going to happen and I need a FUN way to surprise her with the information! I thought about writing her a letter and then sending it so that when she opens it she's surprised. I'm sure there's an even crazier way to break the news! So, i need ideas!Thanks!!!D

- need to make square cuts on your pipe use a ratchething pvc cutter available at any hardware store make sure to use primer on all glued fittings I prefer to use christy's red hot glue with a good purple primer on the threaded fitting use a good pipe dope like blue magic or rectoseal under teflon tape. apply the pipe dope evenly over threads then hold fitting in left hand and starting from back of thread tape away from you to tip of the thread hand tighten then with pipe wrench just give it two turns hope htis helps

- Q:I work at a fire hydrant factory. I am having trouble finding a parking space near the building its very frustrating. I have to walk really far to get to the door. What should I do? Should I tell my boos about my problem?

- Maybe she was a smoker, could be the reason why she was somewhat insulted anyway Congratulations,..Your a Super Hero, the World needs you man,lmhoff,GRAB THAT BLANKET STICK OUT YOUR CHEST,I can see it now big circle on your chest,..cigarette in middle line drawn across,..lol,.. glad the guy is alright,hope he learned a lesson, don't smoke and ride,..okay enough already,Peace

- Q:What do you mean by pipe joint 3/4-150?

- It's not very clear. There may be an interface screw with a size of 3 / 4, 15 teeth, and a O ring

- Q:a good cheap rod to use with my team daiwa megaforce plus with twitching bar???

- For most locations in the states you will use the line sizing tables in NFPA 54, the Fuel Gas Code, if you are in Canada as your name might suggest, you will want to check with the local authority having jurisdiction over your installation. The line sizing tables for gas are all basically the same, but some local jurisdictions use slight variations of the nationally recognized standards. You want to be careful using online tables; some tables are for liquid lines that are completely different than vapor service lines. Any tables you see that give flow reduction rates for various pipe fittings are for liquid service. Give the inspector a call and just inquire about what tables and standards are used in your area. Because it’s a school your installation may also require schedule 80 pipe, which will need to be color coded and labeled with flow direction arrows as well. It’s worth doing your homework before you start a job like you have there, because you don’t want to have to go back and re-do things later. Probably not the answer you’re looking for, but I hope it helps.

- Q:So,i want to make a Anthony van Leeuwen microscope replica,and i need to make a 1-2 mm glass sphere.I have my torch ready,protective eyewear and gloves,but i am still reluctant to melt glass. Wont it shatter?Any tips on what glass to use?And to prevent shattering?

- The absolute easiest way is to soak overnight with Coca Cola every couple of hour before you go to bed drip a little on each of the fittings, and let it froth and foam use fresh Coke not flat

- Q:No doubt all 3 members of The Shield have talent and can all be given a push in some time of their WWE Career But the WWE cannot push all three at the same time. Rumor is saying that Roman Reigns will turn face soon. Meaning The Shield will most likely split up. Reigns should be the first one to be given a push (imo). He has the look, wrestling ability, and has incredible mic skills to be an entertaining Champion. Hopefully the WWE gives him a push soon. A feud between Reigns and Orton can be entertaining to watch. Your thoughts?

- The Exact Opposite To Yours .. I Hate Winter And Love Spring ..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords