Steel IPE Heavy Weight I Beam in Europe Standard En10025 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel IPE Description:

Steel IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel IPE is usually made of structural steel and is used in construction and civil engineering. The steel IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

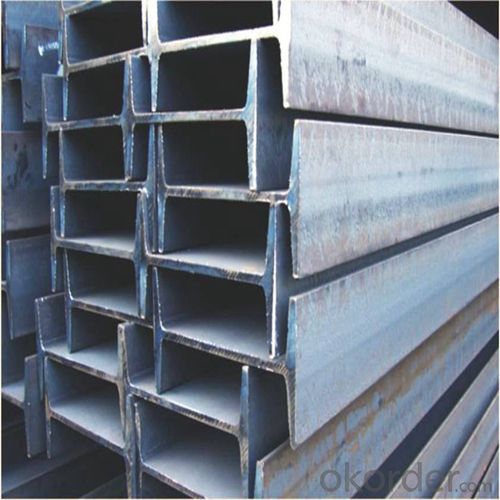

3. Steel IPE Images:

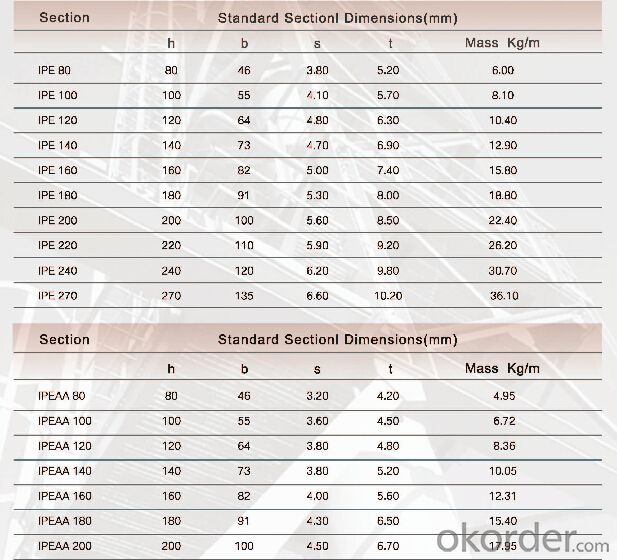

4. Steel IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:What are the different methods of welding steel I-beams?

- Some of the different methods of welding steel I-beams include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW). These methods involve using different types of welding electrodes or wires, shielding gases, and techniques to join the steel beams together.

- Q:Can steel I-beams be used to create mezzanine floors?

- Yes, steel I-beams can be used to create mezzanine floors. Mezzanine floors are intermediate floors that are constructed between the main floors of a building, typically creating additional usable space. Steel I-beams are commonly used in the construction industry due to their strength, durability, and ability to support heavy loads. They are ideal for creating mezzanine floors as they can provide the necessary structural support to accommodate the additional weight and ensure the safety of the structure. Additionally, steel I-beams can be customized to fit the specific dimensions and requirements of the mezzanine floor, making them a versatile and efficient choice for this application.

- Q:What are the typical costs associated with steel I-beams?

- The typical costs associated with steel I-beams can vary depending on several factors. Firstly, the size and weight of the beam will play a significant role in determining the cost. Larger and heavier I-beams will generally be more expensive than smaller ones. Another factor that can affect the cost is the grade of steel used. Different grades of steel have varying levels of strength and durability, and therefore, different price points. Higher-grade steel will typically be more costly than lower-grade options. Additionally, the length of the beam can impact the cost. Longer beams will require more material and may also require specialized transportation, which can increase the overall price. It is also important to consider the quantity needed. Ordering a larger quantity of steel I-beams may result in volume discounts, reducing the cost per unit. Furthermore, market conditions and the location of the supplier can influence the cost. Prices can vary regionally due to factors such as supply and demand, transportation costs, and local competition. To determine the exact costs associated with steel I-beams, it is recommended to contact suppliers or consult pricing guides specific to the steel industry.

- Q:How do steel I-beams perform in earthquake-prone areas?

- Steel I-beams are widely used in earthquake-prone areas due to their excellent performance during seismic events. The inherent strength and ductility of steel make I-beams highly resistant to the lateral forces generated by earthquakes. Their ability to flex and dissipate energy helps absorb and distribute seismic forces, minimizing structural damage and reducing the risk of collapse. Additionally, steel I-beams can be designed to meet specific seismic codes and requirements, further enhancing their performance in earthquake-prone areas.

- Q:What's the difference between plain I-beam and light I-beam? What is light I-beam?

- Ordinary steel processing is ordinary I-beam, Lu, magnesium and other light alloy processing is light construction steel.

- Q:What span is the maximum span for I-beam?

- I-beam is also called steel girder (English name Universal Beam). It is a strip of steel with an I-shaped section. I-beam is divided into ordinary I-beam and light I-beam, H steel three. It is a section steel whose shape is trough.

- Q:Can steel I-beams be used in temporary or relocatable structures?

- Indeed, temporary or relocatable structures can utilize steel I-beams. Renowned for their robustness and endurance, steel I-beams are highly favored in diverse construction undertakings. Their effortless disassembly and reassembly enable effortless relocation or temporary utilization. Furthermore, steel I-beams exhibit exceptional load-bearing capacities, rendering them ideal for sustaining the structure's weight. The versatility and adaptability of steel I-beams establish them as a dependable and effective option for temporary or relocatable structures.

- Q:Are steel I-beams cost-effective compared to other materials?

- Yes, steel I-beams are generally considered cost-effective compared to other materials. They offer high strength-to-weight ratio, durability, and ease of construction, making them a popular choice in various industries. Additionally, steel is widely available, recyclable, and has a long lifespan, reducing maintenance and replacement costs.

- Q:Can steel I-beams be used in residential deck construction?

- Yes, steel I-beams can be used in residential deck construction. Steel I-beams are known for their strength and durability, making them a suitable option for supporting heavy loads in deck structures. They can be used as the main structural support for the deck, providing stability and ensuring the deck's longevity. Steel I-beams are often used in commercial and industrial construction, but they can also be utilized in residential projects, especially in cases where a deck requires extra support due to its size or if it is being built on uneven terrain. However, it is important to consult with a structural engineer or a professional deck builder to ensure that the specific design and construction requirements of the deck are met when using steel I-beams. Additionally, local building codes and regulations should be followed to ensure compliance and safety standards are met.

- Q:What are the environmental implications of using steel I-beams in construction?

- The use of steel I-beams in construction has both positive and negative environmental implications. On the positive side, steel is a highly durable and strong material, which allows for the construction of long-lasting and sturdy buildings. Moreover, steel is recyclable, reducing the need for new production and minimizing waste. However, the production of steel I-beams requires a significant amount of energy and emits greenhouse gases, contributing to climate change. Additionally, the extraction of iron ore and the mining of other materials used in steel production can have adverse environmental impacts, including habitat destruction and water pollution. Therefore, while steel I-beams offer structural advantages, it is crucial to consider their environmental footprint and explore sustainable alternatives whenever possible.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel IPE Heavy Weight I Beam in Europe Standard En10025 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords