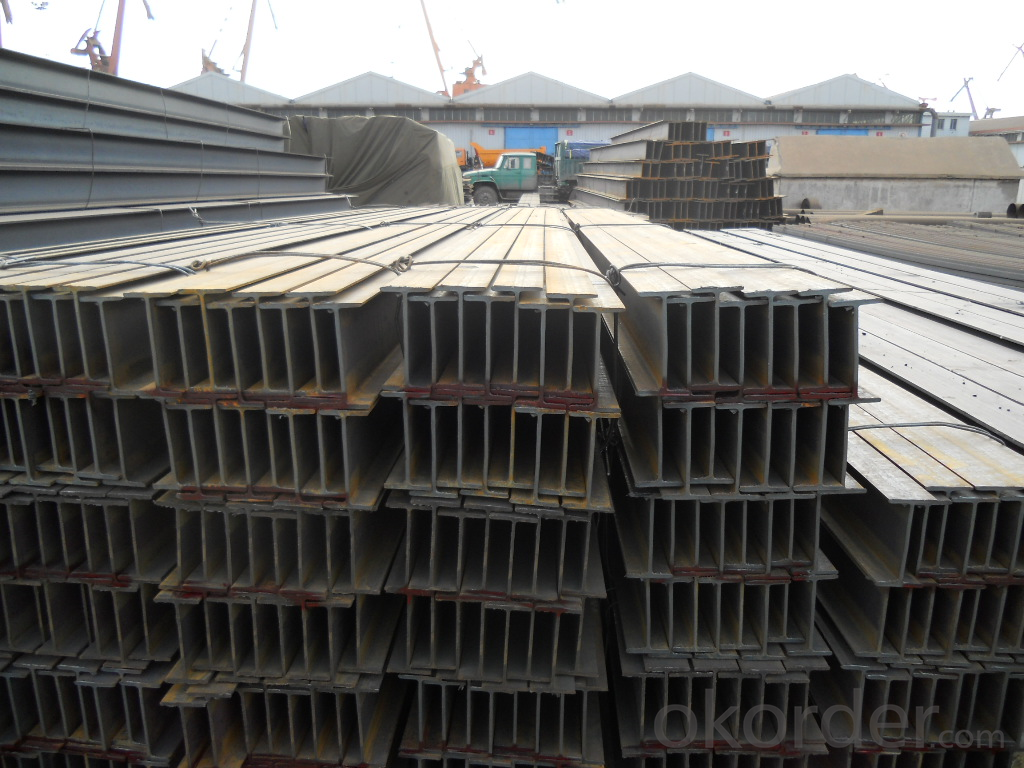

Steel H-Beam for Construction with High Quality and Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Specifications of Steel H-Beam for Construction with High Quality and Competitive Prices

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Usage & Applications of High Quality Hot Rolled Structural Steel H-Beam for Construction

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Steel H-Beam for Construction with High Quality and Competitive Prices

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Steel H-Beam for Construction with High Quality and Competitive Prices

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Images

- Q:How do steel H-beams distribute loads?

- Steel H-beams distribute loads by transferring the weight or force applied to them evenly along their length, utilizing the structural properties of their shape. The horizontal top and bottom flanges resist bending moments, while the vertical web resists shear stress. This distribution of loads allows H-beams to effectively support heavy loads and provide stability in structures such as buildings, bridges, and other load-bearing applications.

- Q:How do steel H-beams contribute to the overall functionality of a building?

- Steel H-beams contribute significantly to the overall functionality of a building by providing structural support and stability. These beams are designed to withstand heavy loads and distribute weight evenly, allowing for larger open spaces and flexible floor plans. They also enhance the building's resistance to lateral forces such as wind and earthquakes, ensuring its safety and durability. Additionally, H-beams facilitate efficient construction as they can be easily fabricated and interconnected, saving time and costs.

- Q:What are the different finishes available for steel H-beams?

- There are several different finishes available for steel H-beams, including hot-dip galvanizing, primed, painted, and bare steel.

- Q:Can steel H-beams be used for supporting airport hangars?

- Yes, steel H-beams can be used for supporting airport hangars. Steel H-beams are commonly used in construction due to their high strength and durability. They provide excellent structural support and can withstand heavy loads, making them ideal for supporting large structures like airport hangars. The H shape of the beams allows for efficient distribution of weight, ensuring stability and preventing any structural failure. Moreover, steel H-beams can be easily fabricated and customized to meet the specific requirements of the hangar, such as size and weight capacity. Overall, steel H-beams are a reliable and cost-effective choice for supporting airport hangars.

- Q:What are the different surface treatments available for steel H-beams?

- There are several surface treatments available for steel H-beams, including primer coating, galvanizing, and paint coatings. Primer coating provides a base layer that enhances corrosion resistance and adhesion of subsequent coatings. Galvanizing involves applying a zinc coating to protect against rust and corrosion. Paint coatings can be applied in various colors and finishes to provide aesthetic appeal and further protect the steel from environmental elements.

- Q:Can steel H-beams be used for both indoor and outdoor applications?

- Yes, steel H-beams can be used for both indoor and outdoor applications. Steel is a highly durable and versatile material that can withstand various weather conditions and environmental factors, making it suitable for both indoor and outdoor use. Whether it is for constructing buildings, bridges, or other structures, steel H-beams offer strength and stability in various settings.

- Q:How are Steel H-Beams installed on-site?

- Steel H-Beams are typically installed on-site through a process involving hoisting and aligning. First, a crane or heavy-duty lifting equipment is used to lift the H-Beams into position. The beams are then aligned according to the required specifications, ensuring that they are level and properly oriented. Once in position, the beams are secured using various methods such as welding, bolting, or using specialized connectors. The installation process requires skilled workers and adherence to safety protocols to ensure a secure and stable structure.

- Q:How do steel H-beams perform in areas with high heat or thermal expansion?

- Steel H-beams perform well in areas with high heat or thermal expansion due to their excellent thermal conductivity and ability to withstand high temperatures without significant deformation. The structural integrity and dimensional stability of steel make it a reliable choice for such environments, as it can effectively dissipate heat and resist thermal expansion, ensuring the structural integrity of the H-beams.

- Q:How do steel H-beams perform in areas with high humidity and moisture?

- Steel H-beams generally perform well in areas with high humidity and moisture. Steel is known for its durability and resistance to corrosion, making it suitable for environments with elevated moisture levels. However, it is important to note that proper maintenance and protective measures should be taken to ensure the longevity of steel H-beams in such conditions. In high humidity and moisture areas, steel H-beams can be prone to corrosion if not adequately protected. Moisture, especially in the presence of oxygen and contaminants, can lead to the formation of rust on the surface of the beams. Rust compromises the structural integrity of the steel, potentially reducing its load-bearing capacity. To prevent corrosion and maintain the performance of steel H-beams in these conditions, various measures can be implemented. One common approach is the application of protective coatings, such as galvanization or painting. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial barrier, protecting the underlying steel from corrosion. Painting with corrosion-resistant coatings provides a similar protective effect. In addition to protective coatings, proper drainage and ventilation systems should be installed to minimize the accumulation of moisture around the H-beams. Regular inspections and maintenance are also crucial to identify and address any signs of corrosion or damage promptly. Overall, steel H-beams are suitable for areas with high humidity and moisture, but preventive measures should be taken to ensure their long-term performance and structural integrity. By implementing protective coatings, drainage systems, and regular maintenance, the risk of corrosion can be significantly reduced, allowing steel H-beams to function effectively in such environments.

- Q:Can steel H-beams be used for exhibition halls or convention centers?

- Yes, steel H-beams can be used for exhibition halls or convention centers. Steel H-beams are commonly used in construction due to their high strength and durability. They provide structural support and can withstand heavy loads, making them suitable for large and open spaces like exhibition halls or convention centers. Additionally, steel H-beams can be easily fabricated and customized to meet specific design requirements and can be used to create large-span structures without the need for excessive columns or supports. Overall, steel H-beams are a popular choice for building exhibition halls or convention centers as they offer strength, flexibility, and cost-effectiveness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel H-Beam for Construction with High Quality and Competitive Prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords