Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

1) Introduction of Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

Steel Grinding Ball is wear-resistant medium for grinding machine use. It is a consumables with big potential market demand for mining, power station, cement plant, chemical industry, etc.

2) Specifications of Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

Size: 15-150mm

Hardness: 58-65HRC

Breakage Rate<0.5%, as usual no

Impact Test>12J/cm2

Endurance Test>10000times

3) Chemical Composition of Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

Material | C | Mn | Si | Cr | S | P | Cu | Mo |

45# | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.25 | - | - | 0.25 | 0.30 |

50Mn | 0.48-0.56 | 0.70-1.00 | 0.17-0.37 | 0.25 | - | - | 0.25 | 0.30 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | 0.25 | - | - | 0.25 | 0.30 |

65Mn | 0.62-0.70 | 0.90-1.00 | 0.17-0.37 | 0.25 | - | - | 0.25 | 0.30 |

B-1 | 0.52-0.65 | 0.60-1.20 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | - | - |

B-2 | 0.50-0.80 | 0.60-0.80 | 0.17-0.37 | 0.90-1.10 | 0.035max | 0.035max | - | - |

B-3 | 0.72-0.92 | 0.70-1.00 | 0.17-0.37 | 0.50-0.90 | 0.035max | 0.035max | - | - |

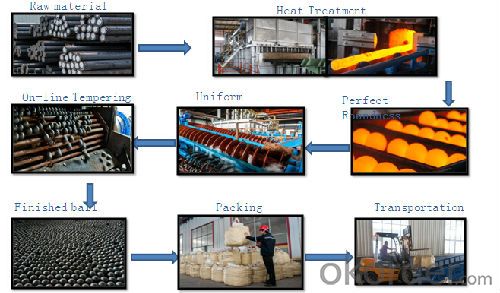

4) Production Process of Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

5) Packing of Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

6) Transportation of Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

- Q:How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q:How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q:What is the casting material?

- Commonly used gray cast iron, malleable cast iron, ductile iron, cast steel, etc., non-ferrous metal casting copper alloy, casting aluminum alloy, casting zinc alloy, etc..

- Q:Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q:Cause of choking of casting parts

- The reason is not in the coated sand, see coating gas evolution, the best use of zircon powder coating (low gas evolution), there is a mold according to a vent needle, this depends on your way is flat or vertical pouring pouring pouring, if vertical pouring, venting pin on the die, and the big piece how could the plane, pouring water flat, a breath, a taboo ah!

- Q:The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q:When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q:Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- Q:After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q:There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

1. Manufacturer Overview |

|

|---|---|

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Steel Grinding Ball with High Hardness & No Breakage & Good Wear Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords