Steel-Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

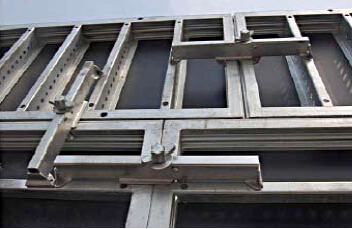

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

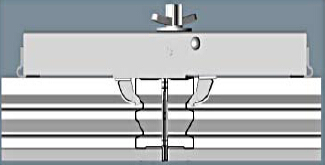

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:How does steel formwork affect the overall fire resistance of a building?

- Steel formwork does not directly affect the overall fire resistance of a building. Fire resistance in a building is primarily determined by the materials used for structural components such as columns, beams, and floors. However, steel formwork can indirectly impact the fire resistance of a building in a few ways. Firstly, steel formwork is often used for constructing concrete structures. Concrete itself has good fire resistance properties, as it is a non-combustible material. When steel formwork is used to mold concrete, it helps create a fire-resistant structure by providing a strong and durable framework for the concrete to be poured into. This ensures that the structure will remain intact under high temperatures and prevent the collapse of the building during a fire. Secondly, steel formwork can also contribute to the fire resistance of a building through its ability to withstand high temperatures. Unlike other types of formwork materials, such as wood or plastic, steel formwork is less susceptible to burning or melting. This means that even in the event of a fire, the steel formwork will not contribute to the spread of flames or release toxic fumes, which can help to contain the fire and minimize its impact on the overall fire resistance of the building. Lastly, steel formwork can also indirectly affect the fire resistance of a building by facilitating the installation of fire protection measures. Steel formwork provides a smooth and sturdy surface, allowing for the easy application of fire-resistant coatings, such as intumescent paint or fireproof sprays. These coatings enhance the fire resistance of the structure by providing an additional layer of protection against heat transfer and fire spread. In summary, while steel formwork itself does not directly impact the fire resistance of a building, it plays a crucial role in creating a fire-resistant structure by providing a strong framework for concrete, withstanding high temperatures, and facilitating the installation of fire protection measures.

- Q:How does steel formwork affect the overall durability of a construction project?

- Steel formwork can have a significant impact on the overall durability of a construction project. One of the key advantages of using steel formwork is its strength and durability. Steel is known for its high tensile strength, which allows it to withstand heavy loads and resist deformation. This strength is crucial in ensuring that the formwork maintains its shape and integrity throughout the construction process. Additionally, steel formwork is highly resistant to wear and tear, making it suitable for multiple uses and reuses. Unlike other materials such as wood, steel does not easily degrade or deteriorate, ensuring that the formwork remains in good condition for long periods. This durability is particularly important in large-scale construction projects that require repetitive formwork installations. Moreover, steel formwork offers excellent dimensional stability. It does not warp or shrink under varying weather conditions, which helps to maintain the accuracy and precision of the concrete structure being formed. This is crucial for ensuring that the final construction project meets the required specifications and standards. The durability of steel formwork also contributes to the overall safety of the construction project. Its strength and stability prevent any potential formwork failure, which could lead to accidents or structural damages during the concrete pouring process. By providing a secure and reliable support system, steel formwork enhances the safety of workers and the long-term structural integrity of the building. Furthermore, the durability of steel formwork translates into cost-effectiveness over the project's lifespan. Its ability to be reused reduces the need for constant replacement, saving time and money on material expenses. Additionally, the reduced maintenance required for steel formwork lowers ongoing maintenance costs, making it a cost-effective choice for construction projects. In conclusion, steel formwork greatly contributes to the overall durability of a construction project. Its strength, resistance to wear and tear, dimensional stability, and safety features ensure that the formwork remains intact throughout the construction process. This durability not only enhances the structural integrity of the building but also provides cost-effectiveness and peace of mind for the project stakeholders.

- Q:What are the different types of formwork corner solutions used in steel formwork?

- There are several different types of formwork corner solutions used in steel formwork, including internal corners, external corners, chamfered corners, and rounded corners. Internal corners are used to create seamless and smooth transitions between walls or columns, while external corners are used to create sharp and precise edges. Chamfered corners are used to create angled or beveled edges, providing a more decorative finish to the concrete structure. Finally, rounded corners are used to create curved or rounded edges, adding a softer and more aesthetically pleasing look to the finished formwork.

- Q:What are the characteristics of steel formwork

- 3, the template adsorption force is small, easy demoulding.4, the number of turnover, generally can be used 50 times.

- Q:What are the different surface finishes available for steel formwork?

- There are several different surface finishes available for steel formwork, depending on the specific requirements and preferences of the project. 1. Smooth finish: This is the most common surface finish for steel formwork. It involves grinding or sanding the surface to create a smooth and even appearance. Smooth finishes are ideal for projects that require a high level of precision and aesthetic appeal. 2. Textured finish: Some projects may require a textured surface finish for better bonding with concrete. This can be achieved through various methods, such as shot blasting or using textured form liners. Textured finishes provide additional grip and can enhance the bond between the formwork and concrete. 3. Brushed finish: Brushed finishes involve using wire brushes or abrasive pads to create a slightly rougher surface. This finish is often chosen for applications where slip resistance is important, such as on ramps or walkways. 4. Etched finish: Etching is a chemical process that creates a matte or patterned finish on steel formwork. This finish is commonly used for decorative purposes, as it can create unique designs or patterns on the surface. 5. Galvanized finish: Galvanizing is a coating process that involves applying a layer of zinc to the steel formwork. This finish provides excellent corrosion resistance, making it suitable for projects in harsh or corrosive environments, such as marine or industrial applications. 6. Powder-coated finish: Powder coating is a durable and decorative finish that involves applying a dry powder to the steel formwork and then curing it with heat. This finish is available in a wide range of colors and provides excellent resistance to impact, chemicals, and UV radiation. It's important to consider the specific requirements of the project, such as durability, aesthetics, and environmental conditions, when selecting the appropriate surface finish for steel formwork. Consulting with a structural engineer or formwork supplier can help determine the best finish for the intended application.

- Q:Can steel formwork be used for structures with high impact resistance requirements?

- Yes, steel formwork can be used for structures with high impact resistance requirements. Steel is known for its strength and durability, making it suitable for withstanding high impact loads. It has a high strength-to-weight ratio, providing excellent resistance against impact forces. Steel formwork systems are commonly used in construction projects that require structures to withstand heavy loads or potential impacts, such as bridges, tunnels, and high-rise buildings. Additionally, steel formwork can be easily fabricated and assembled, allowing for quick and efficient construction of structures with high impact resistance requirements.

- Q:How does steel formwork contribute to the overall sustainability credentials of the project?

- Steel formwork contributes to the overall sustainability credentials of a project in several ways. Firstly, steel is a highly durable material that can be reused multiple times, reducing the need for constant replacement and minimizing waste generation. This not only saves costs but also reduces the environmental impact associated with the production and disposal of formwork materials. Additionally, steel formwork is known for its strength and stability, allowing for efficient and accurate construction processes. This results in reduced material waste and optimized resource utilization. The use of steel formwork also enables faster construction cycles, leading to shorter project durations and decreased energy consumption. Moreover, steel is a recyclable material, meaning that at the end of its life cycle, it can be easily recycled and transformed into new products, reducing the demand for virgin materials and the associated carbon emissions. This circular approach to materials management enhances the sustainability of the project and contributes to a more resource-efficient construction industry. Furthermore, steel formwork offers design flexibility, allowing for the creation of complex shapes and structures. This versatility promotes innovative architectural solutions that can potentially optimize energy efficiency and enhance the overall sustainability of the building design. Lastly, steel formwork can improve the safety and health standards on a construction site. Its robustness and stability ensure a secure working environment, reducing the risk of accidents and injuries. By prioritizing worker well-being, steel formwork contributes to the sustainable development of the project by fostering a responsible and ethical approach to construction practices. In summary, steel formwork contributes to the overall sustainability credentials of a project by reducing waste generation, optimizing resource utilization, enabling faster construction, promoting circular material management, enhancing design flexibility, and prioritizing worker safety.

- Q:How does steel formwork handle concrete temperature differentials?

- Steel formwork is a popular choice for concrete construction due to its durability and strength. When it comes to handling concrete temperature differentials, steel formwork offers several advantages. Firstly, steel has a high coefficient of thermal conductivity, meaning it can quickly absorb and distribute heat. This property allows steel formwork to efficiently dissipate the heat generated during the hydration process of concrete. As a result, steel formwork helps to minimize the risk of thermal cracking caused by temperature differentials. Furthermore, steel formwork is known for its dimensional stability. Unlike other materials like wood, steel does not expand or contract significantly with temperature changes. This stability ensures that the formwork maintains its shape and integrity, even when exposed to varying concrete temperatures. It helps to prevent any distortions, warping, or bulging that could affect the quality and appearance of the concrete structure. Additionally, steel formwork is resistant to fire and high temperatures, making it suitable for handling concrete that undergoes rapid temperature changes, such as in hot weather conditions or during the curing process. Its ability to withstand extreme temperatures without deforming or losing its structural integrity ensures that the formwork remains intact and provides the necessary support and containment for the concrete. In summary, steel formwork effectively handles concrete temperature differentials by efficiently dissipating heat, maintaining dimensional stability, and withstanding high temperatures. These properties contribute to the overall quality and durability of the concrete structure, while minimizing the risk of thermal cracking and other issues caused by temperature variations.

- Q:What are the considerations when designing steel formwork for underground utilities?

- When designing steel formwork for underground utilities, there are several important considerations to keep in mind. Firstly, the formwork must be able to withstand the pressure and weight of the surrounding soil and any potential water infiltration. It is crucial to ensure that the formwork is strong and stable enough to prevent any collapse or deformation during and after the pouring of concrete. Secondly, the formwork design should allow for easy installation and removal. Accessibility and maneuverability are key factors, as underground utilities can often be located in tight spaces or areas with limited access. The formwork should be designed in such a way that it can be easily assembled and disassembled without causing damage to the surrounding infrastructure. Additionally, the formwork needs to be corrosion-resistant to withstand the potentially corrosive environment of underground utilities. Steel formwork should be properly coated or treated to prevent rust and deterioration over time. Lastly, consideration should be given to the formwork's compatibility with other construction materials and techniques. The design should integrate well with other components of the underground utility system and accommodate any necessary connections or interfaces. Overall, the design of steel formwork for underground utilities requires careful attention to strength, stability, accessibility, corrosion resistance, and compatibility with other construction elements.

- Q:What are the common cost-saving strategies when using steel formwork?

- Some common cost-saving strategies when using steel formwork include reusing the formwork for multiple projects, accurately measuring and cutting the formwork materials to minimize waste, properly maintaining and storing the formwork to prolong its lifespan, and utilizing innovative formwork systems that allow for faster installation and dismantling.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords