Steel Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

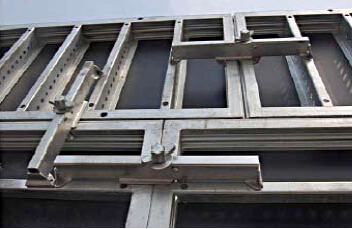

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

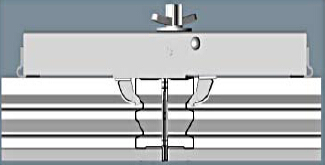

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:How does steel formwork affect the overall construction schedule?

- The overall construction schedule can be significantly affected by steel formwork. Steel formwork possesses durability and the capability to withstand multiple uses, making it advantageous over traditional timber formwork. Its reusability for various projects reduces the time required for formwork installation and removal. Enhanced efficiency and speed in construction are also achieved through the use of steel formwork. Its prefabricated nature allows for easier assembly and disassembly, resulting in faster construction cycles. This ultimately accelerates the overall construction schedule, saving time and increasing productivity. In addition, steel formwork provides a higher level of accuracy and precision in shaping concrete structures. The rigid nature of steel formwork consistently achieves the desired shape and dimensions of the concrete elements, reducing the need for rework or adjustments. This leads to faster curing times for concrete, facilitating quicker progress in the construction schedule. Moreover, steel formwork enhances safety on construction sites. Its robust structure provides stability and reduces the risk of accidents or collapses, enabling construction activities to proceed smoothly without safety-related delays. However, it is important to note that the use of steel formwork may require additional resources and expertise. The initial cost of steel formwork can be higher than that of traditional timber formwork, and specialized equipment may be necessary for its handling and installation. Adequate training and knowledge of steel formwork systems are essential to ensure its proper use and maximize its benefits. In conclusion, the utilization of steel formwork has several positive impacts on the construction schedule, including reduced installation and removal times, increased efficiency, ensured accuracy, improved safety, and accelerated curing. However, careful planning, resource allocation, and expertise are crucial to fully harness the potential of steel formwork in construction projects.

- Q:What are the considerations when designing steel formwork for architectural facades?

- When designing steel formwork for architectural facades, there are several important considerations that need to be taken into account. These considerations include: 1. Structural integrity: The formwork must be designed to withstand the weight of the concrete and any additional loads it may be subjected to, such as wind or seismic forces. It should be able to support the weight without any deformation or failure that could compromise the safety of the structure. 2. Aesthetic requirements: Architectural facades often have unique and intricate designs. The formwork should be able to accurately replicate these designs, ensuring that the finished concrete surface meets the desired aesthetic requirements. This may involve the use of custom-made formwork or the incorporation of architectural features within the formwork itself. 3. Ease of assembly and disassembly: The formwork should be designed in such a way that it can be easily assembled and disassembled. This is important for efficiency during construction and for reuse in future projects. The design should allow for quick and simple connections between the formwork elements, minimizing the time and effort required for assembly. 4. Reusability: Steel formwork is often designed to be reusable, which can help reduce construction costs and environmental impact. Considerations should be made to ensure that the formwork can withstand multiple uses without any significant deterioration or loss of performance. 5. Durability: The formwork should be designed to withstand the harsh conditions of construction sites, including exposure to weather, chemicals, and rough handling. The choice of materials and protective coatings should be made to ensure that the formwork can maintain its structural integrity and functionality throughout its lifespan. 6. Safety: Safety is a paramount consideration in construction. The design of the steel formwork should take into account the safety of workers during assembly, disassembly, and concrete pouring. Features such as guardrails, access platforms, and secure connections should be incorporated to ensure the safety of workers. 7. Cost-effectiveness: The design of the formwork should aim to achieve the desired architectural aesthetics while also being cost-effective. This may involve optimizing the design to minimize the amount of steel required or considering alternative formwork materials where appropriate. Overall, designing steel formwork for architectural facades requires a careful balance between structural integrity, aesthetics, ease of assembly, reusability, durability, safety, and cost-effectiveness. By considering these factors, designers can create formwork that meets the requirements of the project while ensuring efficiency and quality in construction.

- Q:What are the different components of a steel formwork system?

- The different components of a steel formwork system typically include steel panels, connectors, pins, wedges, and accessories such as props, scaffolding, and braces. These components work together to create a robust and durable formwork structure for casting concrete.

- Q:How is steel formwork disassembled?

- To ensure a safe and efficient removal, steel formwork is typically disassembled using a systematic approach. The process involves several steps that should be followed: 1. Begin with an inspection: Before disassembling the steel formwork, it is crucial to thoroughly inspect the structure for any signs of damage or wear. This step helps to identify potential hazards and allows for necessary repairs or replacements before starting the disassembly process. 2. Remove accessories: Start by carefully removing any accessories that are attached to the steel formwork, such as scaffolding, support beams, or tie rods. These accessories play a vital role in the stability of the formwork system, so their removal should be done with caution and control. 3. Clear concrete debris: Next, make sure to clear any concrete debris or remnants that may have adhered to the steel formwork. This can be done using tools like hammers, chisels, or wire brushes. Proper cleaning of the formwork ensures a smooth disassembly process and helps prevent any future complications. 4. Dismantle panels: Begin the process of dismantling the steel formwork panels one by one. This is typically achieved by removing the connecting pins, bolts, or screws that hold the panels together. It is important to follow the reverse order of the assembly process, starting from the top and gradually working downwards. 5. Handle and store: As each panel is disassembled, it is essential to handle it with care to avoid any damage or injury. Once disassembled, label the panels properly and store them in a designated area for easy retrieval in the future or for transportation purposes. 6. Conduct post-disassembly inspection: After the complete disassembly of the steel formwork, it is important to carry out a final inspection. This step allows for the identification of any damaged or worn-out components that may require repairs or replacement before the next use. In summary, the disassembly process of steel formwork necessitates careful planning, attention to detail, and adherence to safety guidelines. By following these steps, the formwork can be properly removed while maintaining the integrity of the structure and ensuring the safety of the workers involved.

- Q:How does steel formwork perform in seismic zones?

- Steel formwork performs well in seismic zones due to its high strength and durability. Steel is known for its excellent load-bearing capacity and resistance to bending and shearing forces, making it suitable for withstanding the intense shaking and vibrations caused by earthquakes. In seismic zones, the ground experiences significant movement during an earthquake, which can put immense pressure on the formwork system. Steel formwork, being rigid and robust, is able to withstand these forces without any significant deformation or damage. This ensures the stability and integrity of the structure during and after the seismic event. Additionally, steel formwork offers flexibility in design and construction, allowing for the creation of reinforced concrete structures that are better equipped to handle seismic loads. The use of steel formwork enables the incorporation of additional reinforcement elements, such as steel bars and mesh, which enhance the overall strength and ductility of the structure. This helps in dissipating the energy generated by seismic forces and reducing the risk of structural failure. Moreover, steel formwork is reusable and can be easily dismantled and reassembled, making it a cost-effective and sustainable choice for construction in seismic zones. This flexibility allows for the quick repair and reconstruction of structures in the event of earthquake damage, minimizing downtime and ensuring the safety of occupants. Overall, steel formwork is a reliable and resilient choice for construction in seismic zones. Its strength, durability, and flexibility make it well-suited to withstand the forces generated by earthquakes, ensuring the safety and stability of structures in these high-risk areas.

- Q:Can steel formwork be used for precast concrete cladding panels?

- Indeed, precast concrete cladding panels can be produced using steel formwork. Steel formwork is widely preferred for constructing the molds or forms required for precast concrete components, including cladding panels. The utilization of steel formwork brings about numerous advantages such as remarkable strength, longevity, and precision in dimensions. It can be conveniently shaped and sized according to the desired specifications, enabling intricate designs and patterns to be incorporated into the cladding panels. Furthermore, steel formwork can be repeatedly utilized, rendering it an economical choice for large-scale production of precast concrete cladding panels. Nevertheless, it is crucial to ensure appropriate surface treatment in order to prevent corrosion and uphold the quality and appearance of the cladding panels.

- Q:How does steel formwork contribute to the overall thermal insulation of the building?

- Steel formwork does not directly contribute to the overall thermal insulation of the building. However, it plays a crucial role in creating the structure and shape of the concrete walls, floors, and ceilings, which can indirectly affect the thermal insulation of the building. Steel formwork is used as a temporary mold or framework for pouring concrete during construction. It provides structural support and holds the concrete in place until it hardens and gains its strength. The concrete, on the other hand, acts as a thermal mass, absorbing, storing, and releasing heat energy. The thermal insulation of a building primarily depends on other materials such as insulation boards, windows, doors, and the overall design of the building envelope. These elements are responsible for reducing heat transfer and maintaining a comfortable indoor temperature. However, if the steel formwork is not properly insulated or if there are gaps between the formwork and the insulation, it can create thermal bridges. Thermal bridges are areas where heat can easily transfer from inside to outside or vice versa, resulting in energy loss and reduced thermal performance. To mitigate thermal bridges, it is essential to ensure proper insulation is installed around the steel formwork and to seal any gaps or joints. This can be achieved by adding insulation materials, such as rigid foam boards or spray foam insulation, between the formwork and the concrete. In summary, while steel formwork itself does not contribute to the thermal insulation of the building, its correct installation and proper insulation around it can help prevent thermal bridges and improve the overall thermal performance of the building.

- Q:Can steel formwork be used for projects with limited formwork stripping time?

- Projects with limited formwork stripping time can utilize steel formwork. Steel formwork is renowned for its durability and strength, rendering it suitable for diverse construction ventures. Unlike traditional formwork materials like wood or plywood, steel formwork can withstand higher pressures and loadings, enabling faster construction cycles. High-rise buildings, bridges, and infrastructure projects often employ steel formwork due to its time-sensitive nature. Its inflexible structure facilitates swift assembly and disassembly, minimizing formwork stripping time. Moreover, steel formwork can be reused multiple times, further diminishing construction time and expenses. Additionally, steel formwork guarantees precise dimensional control, ensuring accurate and consistent outcomes. This quality holds particular significance for projects with limited formwork stripping time since any errors or discrepancies in the formwork can result in delays and additional work. Nevertheless, it is essential to acknowledge that installing and removing steel formwork may require skilled labor and specialized equipment. Hence, meticulous planning and coordination are imperative to ensure efficient and safe utilization of steel formwork for projects with limited formwork stripping time.

- Q:Can steel formwork be used for school construction projects?

- Indeed, school construction projects can make use of steel formwork. Steel formwork, being a resilient and versatile construction material, is capable of withstanding the immense loads and pressures encountered within school buildings. It provides a robust and steadfast framework for pouring concrete, thus ensuring the structural integrity of the construction. Furthermore, steel formwork is designed to be reusable, thereby offering a cost-effective option for school construction projects. Its adaptability allows for the creation of various shapes and sizes, catering to the distinct architectural designs typically found in school buildings. Moreover, steel formwork facilitates faster construction times when compared to traditional timber formwork, enabling the swift completion of school projects. In summary, steel formwork represents a fitting and dependable choice for school construction projects.

- Q:What are the considerations when selecting the appropriate steel grade for formwork?

- When selecting the appropriate steel grade for formwork, there are several considerations that need to be taken into account. Firstly, the load-bearing capacity of the steel grade is of utmost importance. The steel should be able to withstand the weight and pressure exerted by the concrete and any additional loads that may be applied during construction. It should be able to maintain its structural integrity without any deformation or failure. Secondly, the corrosion resistance of the steel grade is crucial. As formwork is often subjected to moisture and chemicals present in concrete, it is essential to choose a steel grade that can resist corrosion. This will ensure the longevity and durability of the formwork, avoiding any potential safety hazards or costly repairs. Another consideration is the ease of handling and fabrication. The selected steel grade should be easy to cut, shape, and weld, allowing for efficient and accurate construction of formwork. It should also have good dimensional stability, ensuring that the formwork remains in the desired shape and size during use. The cost-effectiveness of the steel grade is also a significant factor. While it may be tempting to opt for a higher grade steel with superior properties, it is essential to evaluate the project requirements and choose a grade that offers the necessary performance at a reasonable cost. This will help to optimize the budget without compromising on the quality and functionality of the formwork. Lastly, compliance with industry standards and regulations should be considered. The selected steel grade should meet the relevant codes and specifications set by governing bodies to ensure that the formwork meets safety standards and can withstand the intended loads and environmental conditions. By taking these considerations into account, one can select an appropriate steel grade for formwork that ensures structural stability, durability, corrosion resistance, ease of handling, cost-effectiveness, and compliance with industry standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame SF-140 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords