Steel Frame Formwork withAllowable Pressure 60KN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

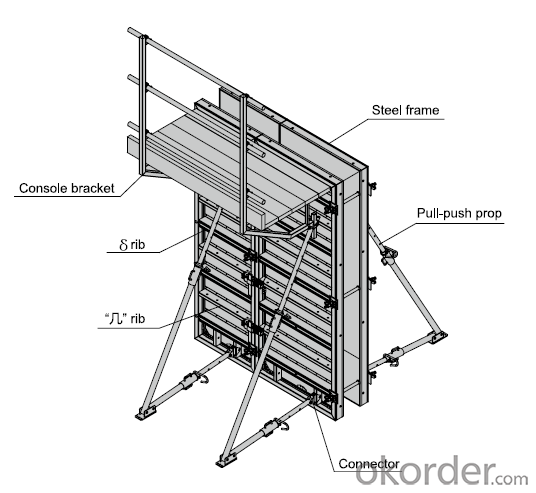

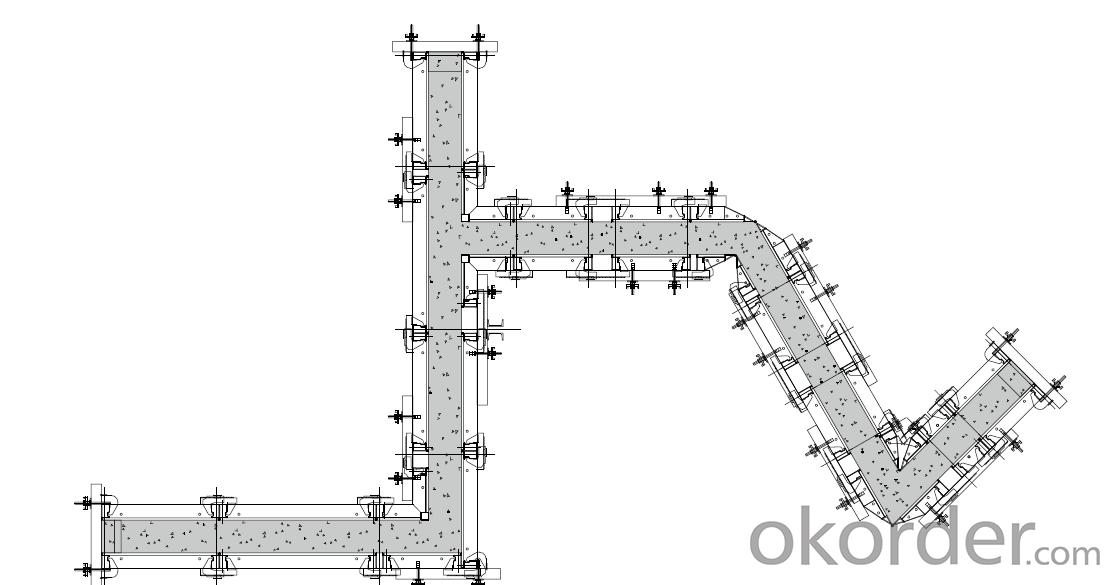

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How does steel frame formwork handle the placement of precast concrete elements within the concrete structure?

- A highly efficient and versatile system specifically designed for handling the placement of precast concrete elements within a concrete structure is steel frame formwork. This system consists of steel frames that are assembled to create a temporary mold or structure for shaping the concrete during construction. When it comes to placing precast concrete elements, the steel frame formwork offers several advantages. Firstly, the steel frames can be easily adjusted and aligned to match the size and shape of the precast elements, ensuring a precise fit. This is crucial as it helps minimize any gaps or irregularities between the precast elements and the surrounding concrete structure. Additionally, the steel frame formwork provides the necessary support and stability for the precast elements. The strong and rigid steel frames can withstand the weight and pressure exerted by the precast elements, ensuring they remain in position during the pouring and curing of the concrete. Furthermore, the steel frame formwork allows for efficient installation and removal of the precast elements. The frames can be easily assembled and disassembled, enabling quick and smooth installation of the precast elements. This saves time and labor costs, making the construction process more efficient. In conclusion, steel frame formwork is a reliable and effective system for handling the placement of precast concrete elements within a concrete structure. Its flexibility, stability, and ease of use make it an ideal choice for ensuring a seamless integration of precast elements into the overall construction process.

- Q:What are the different types of formwork alignment systems used with steel frame formwork?

- There are several different types of formwork alignment systems that are commonly used with steel frame formwork. These alignment systems help ensure that the formwork is properly aligned and positioned during the construction process. One type of alignment system is the spacer system. This system uses spacers or shims to adjust the position of the formwork. Spacers are placed between the formwork and the supporting structure to achieve the desired alignment. This system is simple and easy to use, but it may require frequent adjustments to maintain the alignment. Another type of alignment system is the wedge system. This system uses wedges to adjust the position of the formwork. Wedges are inserted into pre-drilled holes in the formwork and then tapped with a hammer to tighten or loosen the alignment. The wedge system provides a secure and stable alignment, but it may require more time and effort to adjust. Additionally, there is the pin and wedge system. This system uses pins and wedges to secure the formwork into place. Pins are inserted into pre-drilled holes in the formwork and then wedges are inserted to lock the pins into position. This system provides a strong and reliable alignment, but it may be more complex to install and remove. Furthermore, there is the clamp system. This system uses clamps to hold the formwork in place. Clamps are attached to the formwork and then tightened to secure the alignment. The clamp system is versatile and can be easily adjusted, but it may require more clamps to achieve a secure alignment. Lastly, there is the hydraulic system. This system uses hydraulic jacks to adjust the position of the formwork. The jacks are placed under the formwork and then pumped to lift or lower the formwork into the desired alignment. The hydraulic system provides precise and controlled adjustments, but it may require specialized equipment and expertise to operate. Overall, these different types of formwork alignment systems offer various advantages and disadvantages depending on the specific requirements of the construction project. It is important for contractors and construction professionals to carefully consider the alignment system that best suits their needs to ensure a successful and efficient construction process.

- Q:How does steel frame formwork affect the overall cost of concrete construction?

- Steel frame formwork can have a significant impact on the overall cost of concrete construction. While it may initially seem more expensive than other types of formwork, such as timber or aluminum, steel frame formwork offers numerous cost-saving benefits in the long run. Firstly, steel frame formwork is highly durable and can withstand multiple uses without significant wear and tear. This durability ensures that the formwork can be reused multiple times, reducing the need for frequent replacements and lowering overall material costs. Additionally, the strength and rigidity of steel frame formwork allow for faster construction times. This efficiency can result in reduced labor costs as fewer workers are needed to complete the project within a shorter timeframe. The ability to pour concrete at a faster rate also minimizes the cost of on-site labor, as time spent waiting for the concrete to set is reduced. Furthermore, steel frame formwork provides accurate and precise results, resulting in minimal waste and therefore reduced material costs. The formwork's tight fit and smooth finish eliminate the need for excessive concrete patching or rework, saving both time and money. Moreover, steel frame formwork is versatile and adaptable, making it suitable for various construction projects. Its modular design allows for customization and easy assembly, reducing the need for specialized equipment or additional construction materials. Lastly, steel frame formwork offers enhanced safety features, reducing the risk of accidents and injuries. By providing a stable and secure platform for workers, it can help minimize costly delays caused by accidents and ensure a smooth construction process. In summary, while the initial investment in steel frame formwork may be higher compared to other types of formwork, its long-term benefits far outweigh the initial costs. The durability, efficiency, accuracy, versatility, and safety aspects of steel frame formwork contribute to a more cost-effective concrete construction process.

- Q:Can steel frame formwork be used for both horizontal and vertical applications?

- Steel frame formwork is suitable for both horizontal and vertical applications, providing a versatile and sturdy system that can be easily adjusted for different construction projects. It offers a solid structure capable of withstanding the pressure of concrete pouring, making it ideal for horizontal slabs and vertical walls. Moreover, the steel frame formwork system enables rapid and efficient assembly and disassembly, making it a cost-effective option for projects requiring repetitive formwork use. In summary, steel frame formwork is a dependable choice for horizontal and vertical applications in the construction field.

- Q:How does steel frame formwork handle concrete curing in humid conditions?

- Steel frame formwork is highly resistant to the effects of humid conditions during concrete curing. The steel material does not absorb moisture, preventing any potential damage or warping. Additionally, the tight joints and secure connections of steel frame formwork ensure proper sealing, minimizing the risk of moisture penetration. This allows for effective curing of concrete, resulting in a strong and durable structure even in humid environments.

- Q:Can steel frame formwork be used for the construction of agricultural buildings?

- Yes, steel frame formwork can be used for the construction of agricultural buildings. Steel frame formwork is a versatile and durable option for various construction projects, including agricultural buildings. It provides strength, stability, and reusability, making it suitable for agricultural structures that require long-lasting and robust construction materials. Additionally, steel frame formwork can be easily assembled and disassembled, allowing for efficient construction processes in agricultural settings. Whether it is for barns, sheds, or other agricultural buildings, steel frame formwork can be an excellent choice to ensure the structural integrity and longevity of the construction.

- Q:Can steel frame formwork be used in combination with fiber-reinforced concrete?

- Yes, steel frame formwork can be used in combination with fiber-reinforced concrete. Steel frame formwork is a versatile and durable solution for creating the desired shape and structure of concrete elements. It provides stability and support during the casting process. On the other hand, fiber-reinforced concrete contains small fibers such as steel, glass, or synthetic materials that improve its properties, including tensile strength, durability, and crack resistance. When using steel frame formwork with fiber-reinforced concrete, the steel frame provides the necessary support and stability while the fiber-reinforced concrete adds additional strength and durability to the structure. The combination of these two materials allows for the construction of more robust and resilient concrete elements. Furthermore, fiber-reinforced concrete can help reduce the formation of cracks and increase the overall lifespan of the structure. This is particularly beneficial in applications where high tensile strength and resistance to cracking are required, such as in industrial floors, bridge decks, or precast elements. In conclusion, steel frame formwork can be effectively used in combination with fiber-reinforced concrete to enhance the structural integrity and durability of concrete elements. This combination allows for the construction of stronger and more resilient structures that can withstand various environmental and load conditions.

- Q:How is steel frame formwork constructed?

- The construction of steel frame formwork involves assembling steel panels into a rigid framework, which acts as a mold for pouring concrete. The process consists of several steps: 1. Ground preparation: Prior to construction, the site is leveled and made stable to support the weight of the steel frame formwork. 2. Assembly of the framework: Steel panels are connected together using various fastening systems, such as bolts or clamps, to create a strong framework. The panels are designed to interlock, ensuring the formwork's stability. 3. Installation of reinforcement: If necessary, steel reinforcement bars are placed within the formwork to enhance the strength of the concrete structure. These bars are positioned according to the structural design in a grid pattern. 4. Installation of shuttering: Plywood or other suitable materials are attached to the outer face of the steel frame formwork to achieve the desired shape and dimensions for the concrete structure. These shuttering panels are secured using screws or nails. 5. Alignment and leveling: The formwork is precisely aligned and leveled using adjustable props or wedges to ensure the accuracy and quality of the concrete structure. This step is crucial for meeting the desired specifications. 6. Pouring of concrete: Once the formwork is properly set up, concrete is poured into it using a concrete pump or other appropriate methods. Special care is taken to prevent any leakage or seepage of concrete. 7. Curing and removal: After pouring the concrete, it is allowed to cure and gain strength for a specific period, usually a few days. Once the concrete is adequately hardened, the formwork is dismantled by removing the shuttering panels and props, leaving behind a solid concrete structure. In summary, steel frame formwork is a versatile and efficient construction technique that enables swift and precise construction of concrete structures. It provides a robust and long-lasting framework for pouring concrete, resulting in high-quality and accurate structures.

- Q:Can steel frame formwork be used for the construction of healthcare facilities?

- Yes, steel frame formwork can be used for the construction of healthcare facilities. Steel frame formwork is a versatile and durable construction technique that is commonly used in various building projects, including healthcare facilities. This formwork system consists of steel frames, which are designed to support the weight of the concrete and other construction materials during the pouring and curing process. There are several advantages to using steel frame formwork in the construction of healthcare facilities. Firstly, steel is a strong and rigid material that can withstand heavy loads, making it suitable for large-scale construction projects. Secondly, steel formwork is highly durable and can be used multiple times, reducing the overall construction costs. Additionally, steel frame formwork provides a smooth and even surface finish, which is essential for the construction of healthcare facilities that require sanitary and hygienic conditions. Moreover, steel frame formwork allows for efficient construction processes, as it is easy to assemble and disassemble. This saves time and labor costs during the construction phase. Additionally, the flexibility of steel formwork allows for customization and adaptability to meet specific design requirements of healthcare facilities. It is important to note that the use of steel frame formwork for healthcare facilities should comply with the relevant building codes and regulations. Proper engineering and design considerations must be taken into account to ensure the structural integrity and safety of the building. In conclusion, steel frame formwork is a suitable construction method for healthcare facilities. Its strength, durability, and flexibility make it an ideal choice for constructing buildings that require high standards of hygiene and functionality.

- Q:Are there any specific design considerations for steel frame formwork?

- Yes, there are several specific design considerations for steel frame formwork. Firstly, the design should ensure that the steel frame is strong and rigid enough to support the weight of the concrete being poured. This involves determining the appropriate size and dimensions of the steel members, as well as the spacing and arrangement of the supports. Another important consideration is the ease of assembly and disassembly of the formwork. Steel frame formwork should be designed in a way that allows for quick and efficient installation and removal, as this can significantly impact the overall construction timeline and cost. Additionally, the design should take into account the potential for lateral forces, such as wind or concrete pressure, and ensure that the steel frame formwork is adequately braced and supported to resist these forces. This may include the use of diagonal bracing or tie rods to increase stability and prevent deformation of the formwork. The design should also address the issue of formwork deflection. Steel frames may have a tendency to deflect under the weight of the concrete, which can result in uneven surfaces or dimensional inaccuracies. To mitigate this, the formwork should be designed with sufficient stiffness and rigidity to minimize deflection and maintain the desired shape and dimensions of the concrete elements. Furthermore, the design should consider the reusability of the steel frame formwork. Steel is a durable material, and properly designed formwork can be used for multiple construction cycles, reducing waste and overall project costs. This requires attention to detail in terms of material selection, surface treatment, and overall durability of the formwork components. In summary, specific design considerations for steel frame formwork include strength and rigidity, ease of assembly and disassembly, resistance to lateral forces, prevention of formwork deflection, and reusability. A well-designed steel frame formwork system can contribute to efficient and cost-effective construction processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork withAllowable Pressure 60KN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords