Steel Frame Formwork with Thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

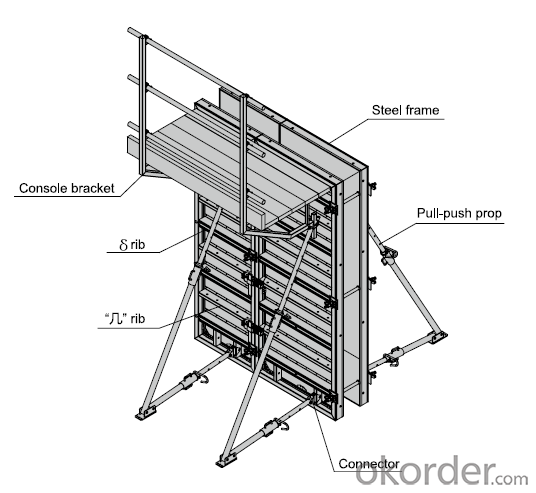

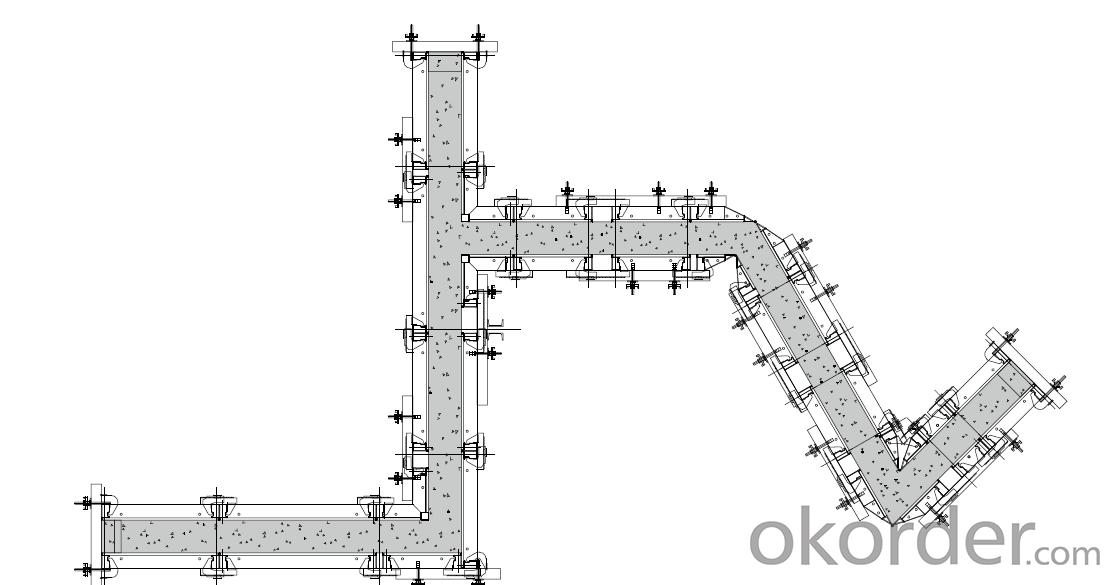

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How does steel frame formwork handle architectural features such as openings and recesses?

- Steel frame formwork proves its versatility in handling architectural elements like openings and recesses. The flexibility of steel frame formwork allows it to adapt to different shapes and sizes. When it comes to openings, like doors and windows, steel frame formwork effortlessly incorporates these features into the structure. The steel frames can be adjusted or modified to perfectly match the dimensions of the openings, guaranteeing a precise fit. This accuracy in placing doors and windows is vital for the overall aesthetic appeal and functionality of the building. Likewise, recesses in the form of niches or alcoves seamlessly blend into the steel frame formwork. These recessed areas are measured accurately and integrated into the formwork design, ensuring that the final structure will possess the desired architectural features. Furthermore, steel frame formwork allows for the inclusion of additional architectural elements such as columns, beams, and facades. The steel frames can be easily modified or adjusted to accommodate these elements, providing a solid framework for their installation. In summary, steel frame formwork offers exceptional adaptability and flexibility in handling architectural features. Its capacity to accurately incorporate openings, recesses, and other elements guarantees that the final construction will meet the intended architectural design and specifications.

- Q:What are the different types of lifting devices used with steel frame formwork?

- There are several types of lifting devices that are commonly used with steel frame formwork in construction projects. These devices are designed to safely lift and move the formwork components, allowing for efficient and effective installation and removal. 1. Tower Cranes: Tower cranes are commonly used in large-scale construction projects. These cranes have a tall tower structure and a rotating arm that can lift and move heavy loads. Tower cranes are often used to lift and position steel frame formwork components, ensuring precise placement. 2. Mobile Cranes: Mobile cranes are versatile lifting devices that can be easily transported to different construction sites. These cranes are equipped with a telescopic boom and a hook or grab attachment, allowing for efficient lifting and moving of steel frame formwork. Mobile cranes come in various sizes and capacities to suit different project requirements. 3. Forklifts: Forklifts are commonly used in construction sites to lift and transport heavy materials. They have a pair of forks at the front that can be inserted under the steel frame formwork components to lift and move them. Forklifts are ideal for smaller-scale projects or areas with limited space. 4. Hoists: Hoists are vertical lifting devices that are commonly used in construction projects. They can be fixed or portable and are often used to lift and lower steel frame formwork components. Hoists are typically operated using an electric or manual system and can be easily controlled to ensure precise positioning. 5. Chain Blocks: Chain blocks, also known as chain hoists, are manual lifting devices that use a chain and pulley system to lift and move heavy loads. They are commonly used in areas where electricity is not readily available or where precise control is required. Chain blocks are often used to lift and position steel frame formwork components in smaller construction projects. Overall, the different types of lifting devices used with steel frame formwork provide construction teams with a range of options to efficiently and safely handle these components. The choice of lifting device depends on the scale of the project, the available space, and the specific requirements of the formwork installation and removal process.

- Q:How does steel frame formwork handle concrete pouring and vibration?

- The effective handling of the concrete pouring and vibration process is achieved through the use of specially designed steel frame formwork. This formwork employs a rigid structure, acting as a support for the weight of the fresh concrete and facilitating the desired formwork configurations. To maintain stability and prevent any movement or displacement during concrete pouring, the steel frame formwork is securely fixed in position. This is essential for preserving the integrity and accuracy of the final structure. The steel frame offers a sturdy framework, enabling the smooth and efficient pouring of concrete. In terms of vibration, the steel frame formwork is engineered to withstand the forces generated during this process. Vibration is crucial for eliminating air pockets or voids within the concrete, ensuring a durable end product. By absorbing and distributing the vibration energy, the steel frame formwork prevents any deformation or damage to the structure. Furthermore, the steel frame formwork often incorporates additional features to enhance the concrete pouring and vibration process. These may include adjustable leveling devices, tie rods, and clamps, which provide extra support and stability. This allows for precise control over the pouring and vibration, resulting in a high-quality concrete structure. Overall, the steel frame formwork is specifically designed to handle the challenging conditions of concrete pouring and vibration. Its strong construction and advanced features offer the necessary strength, stability, and control required for a successful and efficient concrete construction process.

- Q:What are the considerations for selecting the appropriate formwork for different concrete curing durations?

- When selecting the appropriate formwork for different concrete curing durations, several considerations need to be taken into account. Firstly, the type of formwork material should be chosen based on its ability to withstand the curing duration without warping or deteriorating. For shorter curing periods, materials like timber or plywood may be suitable, while for longer periods, steel or aluminum formwork may be more appropriate. The complexity and intricacy of the concrete structure also play a role in formwork selection. For complex shapes or intricate designs, modular formwork systems that can be easily adjusted and reused may be preferred. On the other hand, simple and repetitive structures may benefit from traditional formwork methods, such as timber or steel frames. The cost and availability of formwork materials should also be considered. Some materials may be more expensive or harder to find, which could affect the overall project budget and timeline. It is important to strike a balance between the desired curing duration and the cost-effectiveness of the chosen formwork system. Lastly, safety is paramount when selecting formwork. The chosen formwork system should be able to support the weight of the wet concrete and any additional loads, ensuring the stability and integrity of the structure during the curing process. Adequate bracing and shoring must be considered to prevent any collapse or failure. In summary, the considerations for selecting the appropriate formwork for different concrete curing durations include the type of formwork material, complexity of the structure, cost and availability, and ensuring safety and stability throughout the curing process.

- Q:Are there any safety precautions that need to be taken when using steel frame formwork?

- When using steel frame formwork, there are several safety precautions that should be taken into account. To begin with, it is crucial to properly install and secure the steel frame formwork to prevent any potential collapse or instability. This involves carefully inspecting the connections and supports to ensure their structural integrity. Moreover, it is essential for workers to always wear appropriate personal protective equipment (PPE) such as helmets, safety glasses, gloves, and steel-toed boots to safeguard themselves from potential hazards on the construction site. Furthermore, it is of utmost importance to adhere to the manufacturer's instructions and guidelines for the steel frame formwork in order to ensure correct usage. This may entail maintaining proper spacing and alignment of the formwork components and employing suitable bracing and supports. Regular inspections of the steel frame formwork must also be carried out to identify any indications of damage or wear. Any compromised or deteriorated components should be promptly replaced to uphold the integrity and safety of the formwork system. Additionally, it is crucial to consider the weight and load-bearing capacity of the steel frame formwork. Overloading the formwork can lead to collapse or instability, hence it is imperative to adhere to the specified weight limits and distribute the load evenly. Lastly, effective communication and coordination among the construction team are vital when utilizing steel frame formwork. Clear instructions and warnings should be communicated to all individuals working in the vicinity to ensure their safety. By diligently adhering to these safety precautions, the risk of accidents and injuries can be significantly minimized when employing steel frame formwork.

- Q:Cross stitch mounting, with steel frame or wooden frame

- Set a good position on the wall, in accordance with the box above the mouth of the two fixed position, with the impact of drilling holes

- Q:Can steel frame formwork be used in projects with limited construction site amenities or utilities?

- Yes, steel frame formwork can be used in projects with limited construction site amenities or utilities. Steel frame formwork is a versatile and durable solution that can be easily transported and assembled on-site. It does not rely on external utilities such as electricity or water, making it suitable for projects in remote areas or with limited access to amenities. Additionally, steel frame formwork can be reused multiple times, reducing the need for frequent material replacements and minimizing the demand for on-site resources.

- Q:What are the different types of alignment devices used with steel frame formwork?

- The different types of alignment devices used with steel frame formwork are adjustable formwork clamps, alignment wedges, formwork pins, and formwork braces. These devices help ensure accurate and precise alignment of the formwork components during construction.

- Q:Can steel frame formwork be used in combination with sustainable building materials?

- Yes, steel frame formwork can be used in combination with sustainable building materials. Steel formwork provides a durable and reusable solution for creating the framework of a building, while sustainable materials such as bamboo, reclaimed wood, or recycled concrete can be used for the actual construction. This combination allows for efficient and eco-friendly construction processes, reducing waste and promoting sustainability in the building industry.

- Q:Can steel frame formwork be used for both slab and foundation construction?

- Yes, steel frame formwork can be used for both slab and foundation construction. Steel frame formwork offers a versatile and durable solution for constructing both slabs and foundations. Its strong and sturdy design allows for easy assembly and disassembly, making it suitable for various construction projects. Additionally, steel frame formwork provides excellent support and stability, ensuring the quality and integrity of slab and foundation structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork with Thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords