Steel-frame Formwork for Corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

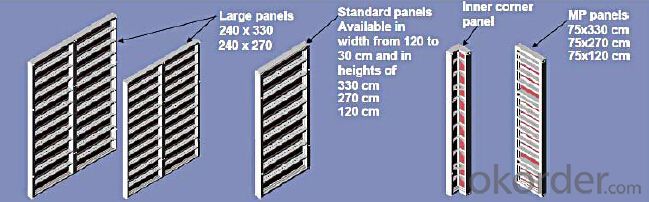

◆ The selection of panels.

◆ Kinds of panel connectors.

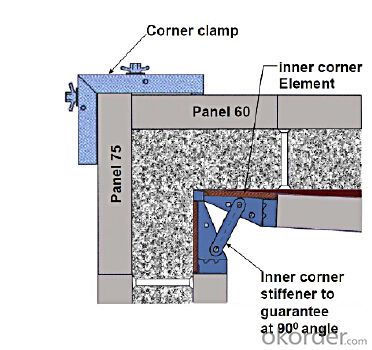

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:Can steel formwork be used for industrial structures?

- Indeed, steel formwork proves to be a viable option for constructing industrial structures. This method involves utilizing steel panels or sheets to establish temporary molds or frameworks, which then hold and shape the concrete throughout the construction process. The utilization of steel formwork is particularly favored in industrial construction due to its robustness, durability, and capacity to endure heavy loads and high pressures. The construction of industrial structures often necessitates formwork systems that can withstand the weight of substantial concrete pours and provide ample support during the curing phase. Steel formwork showcases these qualities, rendering it an ideal selection for industrial projects. Furthermore, steel formwork guarantees exceptional dimensional accuracy, ultimately ensuring precise and consistent outcomes in the construction of industrial structures. Additionally, it can be easily adjusted and reused, leading to cost savings and improved efficiency throughout the construction process. Another notable advantage of steel formwork lies in its ability to withstand adverse weather conditions and extreme temperatures, thus rendering it suitable for a diverse range of industrial settings. Its resistance to warping, cracking, and other forms of damage ultimately safeguards the structure's integrity and longevity. Moreover, steel formwork can be customized to meet the specific requirements of various industrial structures, thereby allowing for flexibility in design and construction. Its ease of assembly and disassembly facilitates faster construction cycles and reduces overall project timelines. To conclude, steel formwork emerges as an exceedingly suitable choice for industrial structures due to its strength, durability, dimensional accuracy, weather resistance, and flexibility. The numerous advantages it offers over alternative formwork materials position it as the preferred option within the construction industry.

- Q:Is steel formwork suitable for high-rise construction?

- High-rise construction can indeed utilize steel formwork, which offers numerous advantages. Firstly, steel formwork possesses exceptional strength and durability, enabling it to withstand the immense pressures and loads associated with tall building construction. This feature ensures the safety and stability of the structure throughout the construction process. Secondly, steel formwork boasts exceptional versatility, allowing for easy customization to meet the specific requirements of high-rise construction. It can be designed and fabricated into various shapes and sizes, providing flexibility in creating different structural elements like walls, columns, and slabs. This adaptability facilitates efficient construction and minimizes the need for extensive modifications or adjustments. Moreover, the reusability of steel formwork makes it a cost-effective option for high-rise construction projects. By eliminating the constant need for new formwork materials, the overall construction costs are reduced. This sustainability aspect also contributes to minimizing waste and promoting resource efficiency. Furthermore, steel formwork ensures high-quality construction for high-rise buildings through its ability to provide a smooth and even surface finish. This characteristic eliminates the requirement for extensive plastering or finishing works, saving time and resources during the construction process. In conclusion, steel formwork is an excellent choice for high-rise construction due to its strength, versatility, reusability, and ability to provide a smooth finish. These qualities make it an ideal option for efficiently and effectively constructing tall buildings.

- Q:Can steel formwork be used for architectural construction projects?

- Yes, steel formwork can be used for architectural construction projects. Steel formwork offers several advantages such as durability, versatility, and reusability, making it a suitable choice for various architectural applications. It provides a strong and rigid structure that can withstand the concrete pressure during casting, allowing for the creation of complex shapes and designs. Additionally, steel formwork can be easily assembled, dismantled, and adjusted, enabling efficient construction processes and reducing overall project timelines.

- Q:What are the different types of ties used with steel formwork?

- There are several different types of ties used with steel formwork, depending on the specific requirements of the construction project. Some of the commonly used types of ties include: 1. Snap Ties: These are the most basic and widely used type of ties. They consist of two parts, a rod and a flat plate, which are connected together using a snap tie wedge. Snap ties are typically used for straight walls and provide a secure connection between the formwork panels. 2. Coil Ties: Coil ties are similar to snap ties, but they have a more flexible design. They consist of a rod with a coil at one end and a flat plate at the other. The coil allows for easy installation and removal of the tie, making it suitable for curved or irregularly shaped walls. 3. She-Bolts: She-bolts are used for connecting steel formwork panels together. They are threaded rods with a flat plate at one end and a nut at the other. She-bolts provide a strong connection and are commonly used for large formwork panels or when high loads need to be supported. 4. Tie Rods: Tie rods are used for securing formwork panels together. They consist of long threaded rods that pass through the formwork panels and are secured with nuts and washers on both ends. Tie rods are commonly used in conjunction with other types of ties to provide additional support and stability to the formwork system. 5. Wing Nuts: Wing nuts are used in combination with tie rods to secure the formwork panels in place. They have a wing-like design that allows for easy tightening and loosening by hand, without the need for additional tools. Wing nuts are commonly used in vertical formwork applications. 6. Cone Anchors: Cone anchors are used to secure the formwork system to the concrete structure. They consist of a cone-shaped anchor with a threaded rod, which is inserted into a pre-drilled hole in the concrete. Cone anchors provide a strong and reliable connection between the formwork and the concrete. These are just a few examples of the different types of ties used with steel formwork. The selection of the appropriate tie depends on factors such as the shape and size of the formwork, the load requirements, and the specific construction project. It is important to consult with a structural engineer or formwork expert to determine the most suitable tie system for a particular application.

- Q:Can steel formwork be used in seismic zones?

- Steel formwork is indeed capable of being employed in seismic zones. Steel possesses formidable strength and durability, enabling it to endure the formidable forces unleashed during an earthquake. The material exhibits a remarkable ability to flex and absorb energy, rendering it highly suitable for deployment in seismic zones. Furthermore, steel formwork confers stability and rigidity upon the structure, guaranteeing its ability to withstand the quivering and shifting caused by seismic activity. Nonetheless, it is essential to take into account other factors such as design, construction techniques, and local building codes to ensure the correct installation and compliance of the steel formwork system with the specific requirements of the seismic zone.

- Q:Can steel formwork be used for elevated walkways?

- Yes, steel formwork can be used for elevated walkways. Steel formwork offers high strength, durability, and stability, making it suitable for supporting the weight and load of an elevated walkway. Additionally, steel formwork provides a smooth and level surface, ensuring a safe and stable walking platform for pedestrians.

- Q:How does steel formwork contribute to the overall energy efficiency of the building?

- Steel formwork contributes to the overall energy efficiency of the building in several ways. Firstly, steel formwork is highly durable and long-lasting, meaning that it can be reused multiple times for different construction projects. This reduces the need for new formwork materials, which in turn reduces the energy and resources required for manufacturing and transportation. Additionally, steel formwork allows for more precise and accurate construction, leading to tighter and better-insulated structures. This improved insulation helps to minimize heat transfer and air leakage, resulting in reduced energy consumption for heating and cooling. By providing a solid and airtight barrier, steel formwork helps to create a more energy-efficient building envelope. Furthermore, steel formwork enables the construction of complex shapes and designs, allowing architects to incorporate energy-efficient features such as passive solar heating, natural ventilation, and daylighting strategies. These design elements can significantly reduce the reliance on artificial lighting, heating, and cooling systems, further enhancing the overall energy efficiency of the building. Lastly, steel formwork is often used in conjunction with other sustainable building materials, such as recycled steel or eco-friendly concrete mixtures. This combination of materials enhances the overall sustainability of the construction process and reduces the environmental impact associated with traditional formwork materials. In summary, steel formwork contributes to the overall energy efficiency of the building through its durability, precision construction, ability to support energy-efficient designs, and use of sustainable materials. By incorporating steel formwork into a construction project, builders can help create buildings that are more energy-efficient, reducing their environmental footprint and promoting sustainable development.

- Q:What is the maximum concrete pressure that steel formwork can withstand?

- The maximum concrete pressure that steel formwork can withstand depends on various factors such as the thickness and type of steel used, the design and construction of the formwork, and the quality of the concrete being poured. However, in general, steel formwork can withstand concrete pressures ranging from 50 to 100 kN/m2 (725 to 1450 psi).

- Q:Are there any specific quality control measures for steel formwork installation?

- Yes, there are specific quality control measures for steel formwork installation. These quality control measures are put in place to ensure that the steel formwork is installed correctly and meets the required standards. One of the key quality control measures is the inspection of the steel formwork before installation. This involves checking the formwork for any damages, defects, or deviations from the required specifications. Any issues found during the inspection should be addressed and resolved before proceeding with the installation. Another quality control measure is the verification of the dimensions and alignment of the steel formwork. This is done to ensure that the formwork is fabricated according to the required dimensions and that it is properly aligned with the structure. Inaccurate dimensions or misalignment can lead to problems during the concrete pouring process and can affect the quality of the final structure. Additionally, quality control measures include checking the stability and strength of the steel formwork. This involves verifying that the formwork is properly braced and supported to withstand the pressure exerted by the concrete. It is important to ensure that the formwork can handle the load without any deformation or failure. Furthermore, the installation process itself should be closely monitored to ensure compliance with the required procedures and standards. This includes checking that the formwork is securely fastened and that all connections are properly made. Any deviations from the installation procedures should be immediately addressed and corrected. Regular inspections and audits should be conducted throughout the installation process to track the progress and identify any potential issues. This allows for timely interventions and corrections, ensuring that the steel formwork installation meets the required quality standards. Overall, specific quality control measures for steel formwork installation are essential to ensure the integrity and safety of the structure. By implementing these measures, any potential issues or defects can be identified and resolved early on, minimizing the risk of costly rework or structural failures.

- Q:How does steel formwork contribute to the overall strength of the structure?

- Steel formwork contributes to the overall strength of a structure in multiple ways. Firstly, steel formwork provides a rigid framework that holds the concrete in place during the pouring and curing process. By ensuring that the concrete is properly contained and supported, steel formwork allows for the formation of a solid and uniform structure. Additionally, steel formwork helps in distributing the loads evenly across the structure. The steel panels and beams used in formwork are designed to withstand the pressure exerted by the wet concrete, ensuring that it is evenly distributed throughout the structure. This helps in preventing any weak spots or areas of uneven load distribution, ultimately enhancing the overall strength and stability of the structure. Furthermore, steel formwork provides reinforcement to the concrete. The steel panels and beams act as a reinforcement system, adding strength and durability to the structure. This reinforcement helps the structure withstand various external forces such as wind, earthquakes, and heavy loads, making it more robust and resistant to damage. Moreover, steel formwork allows for the creation of complex and intricate structures. Due to its high tensile strength and flexibility, steel can be easily shaped and molded into various forms, enabling the construction of unique and architecturally appealing designs. This versatility enhances the overall strength of the structure, as it can be tailored to withstand specific loads and forces. In summary, steel formwork contributes to the overall strength of a structure by providing a rigid framework, distributing loads evenly, reinforcing the concrete, and enabling the construction of complex designs. It plays a crucial role in ensuring that the structure is strong, durable, and capable of withstanding various external forces, making it a preferred choice in construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-frame Formwork for Corner

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords