Steel Frame Corner-Link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

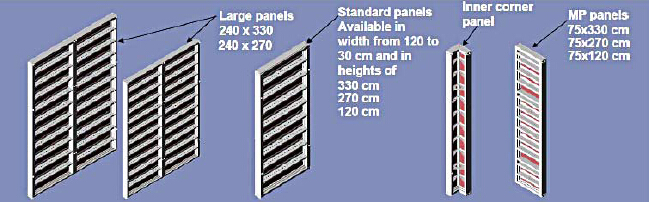

◆ The selection of panels.

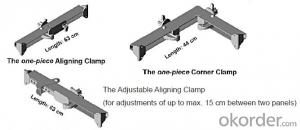

◆ Kinds of panel connectors.

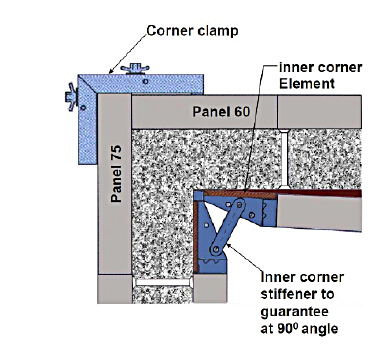

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:Can steel formwork be used for underground construction projects?

- Underground construction projects can indeed utilize steel formwork. Steel formwork proves to be a versatile and enduring option for erecting different types of structures, even those situated below ground level. It offers a robust and firm support system capable of withstanding the pressures and loads associated with underground construction. When it comes to constructing underground projects like tunnels, basements, or subways, steel formwork presents several advantages. Firstly, it boasts a high load-bearing capacity and structural integrity, making it suitable for enduring the weight and pressure exerted by the surrounding soil or water. This ensures the safety and stability of the structure being erected. Furthermore, steel formwork exhibits resistance to corrosion, a crucial attribute in underground construction where exposure to water, humidity, and other corrosive elements is prevalent. This corrosion resistance guarantees the longevity and durability of the formwork, minimizing maintenance needs and extending the lifespan of the structure. Moreover, steel formwork offers design flexibility and can be easily tailored to meet specific project requirements. It can be fabricated into various shapes and sizes, enabling the construction of intricate underground structures. The modular nature of steel formwork also facilitates effortless assembly, disassembly, and reusability, proving advantageous for projects that necessitate frequent formwork repositioning. In conclusion, steel formwork proves to be a suitable choice for underground construction projects due to its strength, durability, corrosion resistance, and design flexibility. It provides a dependable and efficient solution for erecting underground structures, ensuring their safety and longevity.

- Q:How does steel formwork handle formwork stripping?

- Steel formwork is highly durable and strong, allowing it to handle formwork stripping efficiently. The steel panels used in steel formwork systems are designed to be easily removed after the concrete has cured. This is typically achieved by using specialized tools such as formwork release agents, wedges, or hydraulic systems. Steel formwork's robust construction ensures it can withstand the pressure exerted during the stripping process, making it a reliable and effective choice for handling formwork stripping.

- Q:How does steel formwork affect the overall aesthetics of a structure?

- Steel formwork does not have a direct impact on the overall aesthetics of a structure as it is a temporary structure used for shaping and supporting concrete during construction. However, steel formwork can indirectly affect aesthetics by allowing for precise and smooth finishes, resulting in a more visually appealing final product. Additionally, steel formwork's strength and durability ensure structural integrity, which is essential for maintaining the long-term aesthetics of the structure.

- Q:Can steel formwork be used in renovation and refurbishment projects?

- Certainly! Steel formwork is applicable in renovation and refurbishment endeavors. It is a versatile and long-lasting alternative that can be utilized for various construction objectives, encompassing renovation and refurbishment projects. Its sturdiness and stability enable it to be suitable for both small-scale and large-scale ventures. One of the primary advantages of employing steel formwork in renovation and refurbishment undertakings lies in its ability to be reused. Steel formwork can be effortlessly disassembled and reassembled, permitting multiple usages. This renders it an economical choice, as it minimizes the requirement for constant replacement or repair of formwork materials. Furthermore, steel formwork provides a high degree of precision and accuracy, guaranteeing the attainment of the desired shape and dimensions during the renovation or refurbishment process. This is particularly vital when working on intricate designs or when conserving historical structures. Steel formwork also offers exceptional load-bearing capacity, which is imperative in renovation projects where existing structures necessitate reinforcement or alteration. It can endure the pressure exerted by concrete pouring, ensuring the stability and safety of the overall construction. Additionally, steel formwork exhibits resistance to environmental factors such as moisture and extreme temperatures, rendering it suitable for both indoor and outdoor renovation and refurbishment projects. It can endure the deterioration associated with construction activities, ensuring its longevity and dependability. All in all, steel formwork is a trustworthy and efficient choice for renovation and refurbishment projects. Its versatility, reusability, precision, load-bearing capacity, and resistance to environmental factors position it as a preferred option for contractors and builders in these types of construction endeavors.

- Q:I would like to ask the bridge column (D110) steel template thickness should be how much

- The bridge column (D110) column die steel template if the combination of the steel mold, the control panel in 3-5mm more appropriate, to determine the main force depends on the template and rib spacing, material selection.

- Q:What are the typical deflection limits for steel formwork systems?

- The typical deflection limits for steel formwork systems can vary depending on several factors, including the specific design and application requirements of the project. However, there are some general guidelines that are commonly followed. In most cases, the deflection limits for steel formwork systems are typically determined based on the span length and the load applied to the formwork. As a general rule, the deflection limits for steel formwork systems are often limited to L/360 or L/240, where L represents the span length of the formwork. For example, if the span length of the formwork is 10 feet, the deflection limit would be L/360, which equals approximately 0.028 feet or 0.34 inches. This means that the maximum allowable deflection for this formwork system would be 0.34 inches, ensuring that the formwork remains stable and does not significantly deform under the applied load. It is important to note that these deflection limits may be adjusted based on the specific project requirements or industry standards. For instance, in certain high-rise construction projects, stricter deflection limits may be imposed to ensure the structural integrity and overall safety of the formwork system. Ultimately, the deflection limits for steel formwork systems must be carefully considered and evaluated during the design and construction process to ensure the formwork can effectively support the applied loads and maintain its stability throughout the construction process. Consulting with a structural engineer or referring to relevant industry standards can provide more specific and accurate deflection limits for a given steel formwork system.

- Q:What are the different types of steel used in formwork construction?

- Formwork construction utilizes various types of steel, each possessing distinct characteristics and applications. 1. Mild Steel: The most frequently employed steel in formwork construction, mild steel offers affordability, availability, and ease of handling. It is suitable for numerous formwork applications, boasting commendable strength and durability. 2. High Tensile Steel: Distinguishing itself from mild steel, high tensile steel exhibits superior strength and tensile properties, rendering it ideal for robust formwork structures. Its ability to resist bending and deformation under heavy loads makes it particularly fitting for extensive construction projects. 3. Reinforcing Steel: Also referred to as rebar, reinforcing steel reinforces concrete structures in formwork construction. Typically composed of carbon steel, it comes in various grades and sizes. Reinforcing steel is employed to enhance concrete's tensile strength, diminish cracking, and prevent structural failure. 4. Stainless Steel: When prioritizing resistance to corrosion, formwork construction turns to stainless steel. This material excels in environments with harsh conditions or exposure to corrosive substances. Its exceptional resistance to corrosion results in a long-lasting and durable choice for formwork construction. 5. Alloy Steel: Utilized in formwork construction for its augmented properties, alloy steel combines with other elements to enhance its characteristics. This type of steel is commonly employed for its high strength, toughness, and resistance to wear and tear. Formwork systems requiring outstanding performance and durability often rely on alloy steel to withstand substantial loads. Ultimately, the selection of steel for formwork construction hinges upon project-specific requirements, encompassing load-bearing capacity, durability, and corrosion resistance. The appropriate type of steel must be chosen to guarantee the safety and longevity of the formwork structure.

- Q:Can steel formwork be used for both residential and commercial projects?

- Yes, steel formwork can be used for both residential and commercial projects. Steel formwork is a versatile and durable option that is commonly used in construction due to its strength and ability to withstand heavy loads. It can be easily customized and adjusted to meet the specific requirements of different projects, whether they are residential or commercial in nature. Steel formwork offers advantages such as high reusability, fast assembly, and excellent concrete finish. It is commonly used for various applications such as foundations, walls, slabs, columns, and beams in both residential and commercial construction projects.

- Q:What are the different types of access solutions available for steel formwork?

- There are several different types of access solutions available for steel formwork, including scaffold platforms, ladders, staircases, and catwalks. These solutions provide safe and convenient access for workers to reach different areas of the formwork structure during construction or maintenance activities.

- Q:What are the different types of formwork release oils used with steel formwork?

- There are several types of formwork release oils that are commonly used with steel formwork. These oils are used to prevent the concrete from sticking to the steel formwork, making it easier to remove after the concrete has set. Some of the different types of formwork release oils used with steel formwork include: 1. Petroleum-based release oils: These release oils are derived from petroleum and are commonly used in construction projects. They provide a good barrier between the concrete and the steel formwork, preventing adhesion and allowing for easy removal. 2. Vegetable-based release oils: Some formwork release oils are made from vegetable oils, such as soybean or canola oil. These oils are considered to be more environmentally friendly compared to petroleum-based oils. 3. Water-based release agents: Water-based release agents are a popular choice as they are non-toxic and do not emit harmful fumes. They are easy to apply and provide a good release effect on steel formwork. 4. Silicone-based release agents: Silicone-based release agents are known for their excellent release properties. They form a thin layer on the steel formwork, preventing adhesion and ensuring easy removal of the concrete. Silicone-based release agents also provide a high-quality finish to the concrete surface. 5. Polymer-based release agents: Polymer-based release agents are commonly used when a high-quality finish is required on the concrete surface. These agents create a thin film on the steel formwork, preventing adhesion and allowing for easy stripping. It is important to select the appropriate formwork release oil based on the specific requirements of the project, including factors such as the type of concrete being used, environmental considerations, and desired finish of the concrete surface. Consulting with a professional or manufacturer's guidelines is recommended to ensure the correct type of release oil is chosen.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Corner-Link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords