Steel Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

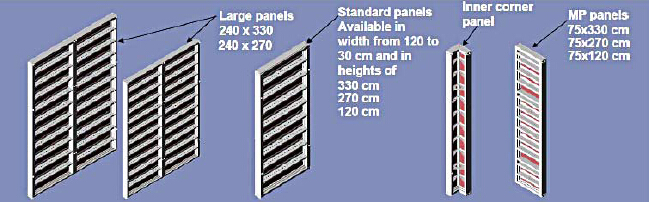

◆ The selection of panels.

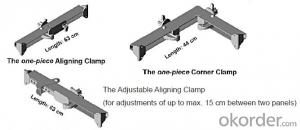

◆ Kinds of panel connectors.

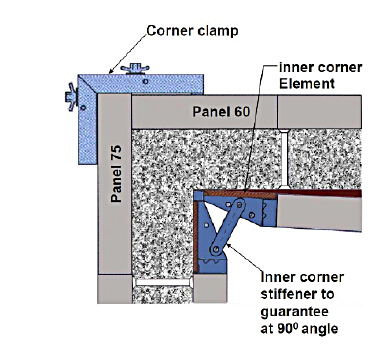

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:What are the different sizes and dimensions of steel formwork?

- The sizes and dimensions of steel formwork can vary depending on the specific requirements of the construction project. However, common sizes range from 1.2 meters to 2.4 meters in width and 2.4 meters to 4.8 meters in length. The thickness of the steel sheets used for formwork can also vary, typically ranging from 3mm to 6mm.

- Q:Can steel formwork be used for decorative concrete finishes?

- Yes, steel formwork can be used for decorative concrete finishes. It provides sturdy support and precise shaping, allowing for intricate designs and smooth finishes in decorative concrete applications.

- Q:Can steel formwork be customized for specific project requirements?

- Yes, steel formwork can be customized to meet specific project requirements. Steel formwork is highly versatile and can be fabricated to any shape, size, or design according to the project needs. It allows for flexibility in construction, ensuring that the formwork precisely fits the desired dimensions and complexities of the structure. Customization of steel formwork enables construction teams to optimize efficiency, accuracy, and safety during the concrete casting process.

- Q:Can steel formwork be used for projects with limited formwork budget?

- Yes, steel formwork can be used for projects with limited formwork budget. Steel formwork is durable, reusable, and has a longer lifespan compared to other types of formwork. It requires less maintenance and can be used for multiple projects, making it a cost-effective option in the long run. Additionally, steel formwork provides better quality finishes and allows for faster construction, reducing labor costs and overall project duration.

- Q:How does steel formwork handle concrete temperature differentials?

- Steel formwork is a popular choice for concrete construction due to its durability and strength. When it comes to handling concrete temperature differentials, steel formwork offers several advantages. Firstly, steel has a high coefficient of thermal conductivity, meaning it can quickly absorb and distribute heat. This property allows steel formwork to efficiently dissipate the heat generated during the hydration process of concrete. As a result, steel formwork helps to minimize the risk of thermal cracking caused by temperature differentials. Furthermore, steel formwork is known for its dimensional stability. Unlike other materials like wood, steel does not expand or contract significantly with temperature changes. This stability ensures that the formwork maintains its shape and integrity, even when exposed to varying concrete temperatures. It helps to prevent any distortions, warping, or bulging that could affect the quality and appearance of the concrete structure. Additionally, steel formwork is resistant to fire and high temperatures, making it suitable for handling concrete that undergoes rapid temperature changes, such as in hot weather conditions or during the curing process. Its ability to withstand extreme temperatures without deforming or losing its structural integrity ensures that the formwork remains intact and provides the necessary support and containment for the concrete. In summary, steel formwork effectively handles concrete temperature differentials by efficiently dissipating heat, maintaining dimensional stability, and withstanding high temperatures. These properties contribute to the overall quality and durability of the concrete structure, while minimizing the risk of thermal cracking and other issues caused by temperature variations.

- Q:How does steel formwork handle concrete curing?

- Steel formwork is an ideal choice for concrete curing due to its durability and strength. The steel formwork provides a rigid framework, ensuring that the concrete maintains its desired shape and structure during the curing process. Additionally, steel formwork allows for easy demolding once the concrete has cured, saving time and effort.

- Q:Are there different sizes of steel formwork available?

- Yes, there are different sizes of steel formwork available.

- Q:Can steel formwork be used for projects with limited formwork storage space?

- Yes, steel formwork can be used for projects with limited formwork storage space. Steel formwork is known for its durability and reusability. It can be easily dismantled and stored in a compact manner, making it a suitable choice for projects with limited storage space. Additionally, steel formwork provides a high level of precision and can be customized to meet specific project requirements, making it a versatile option for various construction projects.

- Q:Can steel formwork be used for both single-use and multi-use applications?

- The utilization of steel formwork can cater to both single-use and multi-use purposes. The decision between these two options heavily relies on the particular demands of the construction project and the allocated budget for formwork. When it comes to single-use applications, steel formwork can be easily customized and manufactured to fit the specific dimensions and shapes necessary for the concrete structure. Once the concrete has solidified, the formwork can be taken off and discarded. This proves to be a cost-effective approach for projects that do not require the formwork for future use. On the flip side, steel formwork can also be designed and produced for multi-use purposes. In this scenario, the formwork is constructed to be sturdy and capable of being reused in multiple construction projects. Steel formwork boasts a longer lifespan compared to materials like timber, making it suitable for repeated use. Moreover, steel formwork can be effortlessly adjusted and reconfigured to accommodate various shapes and sizes, further enhancing its versatility. Nevertheless, it is crucial to note that proper maintenance and care are necessary to ensure the longevity and structural integrity of multi-use steel formwork. Regular inspection, cleaning, and repair of the formwork are essential to prevent any potential issues that may arise from repeated use. To summarize, steel formwork can be employed for both single-use and multi-use purposes, depending on the specific requirements and budget of the construction project. While single-use formwork offers a cost-effective solution, multi-use formwork provides durability and versatility for repeated use.

- Q:How does steel formwork handle concrete pouring and consolidation?

- The strength, durability, and ease of use of steel formwork make it a popular option for concrete pouring and consolidation. There are several advantages to using steel formwork in handling these processes. To start, steel formwork offers a solid and rigid structure that can withstand the pressure exerted by the weight of the concrete. This stability guarantees that the formwork will remain intact during pouring and consolidation, preventing any deformations or collapses that might compromise the quality of the concrete structure. Furthermore, steel formwork is highly resistant to moisture and chemicals found in the concrete mix. This resistance helps maintain the formwork's integrity and durability, ensuring that it doesn't get damaged or corroded during the pouring and consolidation process. As a result, the lifespan of the formwork is extended, and maintenance costs are reduced. In addition, steel formwork allows for efficient and precise concrete placement and consolidation. The smooth surfaces of the formwork enable the concrete to flow easily and evenly, filling all the necessary areas. This eliminates voids and air pockets, resulting in a denser and more structurally sound concrete structure. Moreover, steel formwork can be easily adjusted and customized to meet specific project requirements. Its modular nature allows for simple assembly and disassembly, making it a cost-effective choice for various construction projects. The flexibility of steel formwork also enables the creation of complex shapes and designs, allowing architects and engineers to bring their creative visions to life. In conclusion, the strength, durability, and versatility of steel formwork make it an ideal choice for handling concrete pouring and consolidation. It provides a stable and robust structure that can withstand the weight and pressure of the concrete, while also ensuring efficient and precise placement and consolidation. These qualities make steel formwork a reliable and practical solution for a wide range of construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame corner link for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords