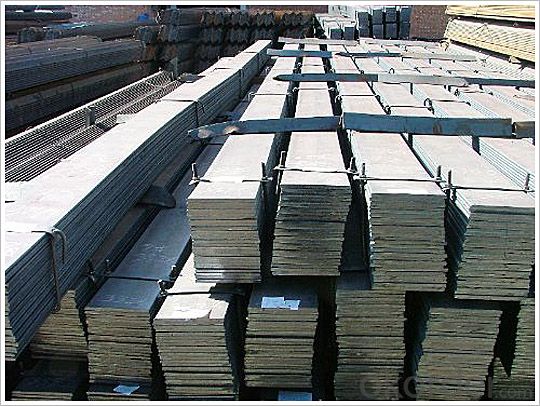

Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled sheet slitted

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q:How do steel flat bars contribute to the overall stability of structures?

- Steel flat bars contribute to the overall stability of structures in several ways. Firstly, they provide structural support and reinforcement, helping to distribute and transfer loads. Due to their flat shape, they can be easily attached to other structural components such as beams and columns, increasing the overall strength and stability of the structure. Furthermore, steel flat bars offer high tensile strength, making them resistant to bending and breaking under heavy loads or external forces. This strength allows them to effectively resist deformation and maintain the structural integrity of the building. Steel flat bars also play a crucial role in preventing lateral movement and buckling. By being strategically placed and connected to other structural elements, they help to resist horizontal forces such as wind or seismic loads, ensuring the stability and safety of the structure during extreme events. Moreover, steel flat bars can be used as bracing elements, providing additional stiffness to the structure. By installing them diagonally or horizontally, they enhance the overall rigidity of the building, reducing the potential for excessive deflection or sway. Additionally, steel flat bars have excellent durability and corrosion resistance properties. This ensures that they can withstand harsh environmental conditions, including moisture and temperature fluctuations, without compromising their strength or stability. Their longevity contributes to the overall stability and longevity of the structure. In summary, steel flat bars contribute to the overall stability of structures by providing structural support, distributing and transferring loads, resisting deformation and lateral movement, enhancing rigidity, and offering durability and corrosion resistance. Their versatile and robust nature makes them an essential component in various construction applications, ensuring the safety and stability of buildings and infrastructure.

- Q:What are the standard dimensions of steel flat bars?

- The industry and application determine the standard dimensions of steel flat bars, which can vary. Nevertheless, there are commonly utilized sizes. Generally, steel flat bars come in widths that range from 10mm to 300mm, and thicknesses that range from 3mm to 25mm. Lengths can differ but are commonly around 6 meters. These dimensions find widespread use in construction, manufacturing, and structural applications. It is crucial to recognize that these are general principles, and regional standards and individual supplier capabilities may cause specific dimensions to differ.

- Q:How do you join two steel flat bars together?

- There are several methods to join two steel flat bars together, depending on the desired strength and aesthetic appeal of the final joint. One common method is welding, where the two flat bars are heated to a molten state and then fused together using an electric arc or gas flame. This creates a strong and durable joint, but it requires skill and equipment to perform properly. Additionally, welding may leave visible weld marks that may need to be smoothed or finished. Another option is using mechanical fasteners such as bolts, screws, or rivets. This method involves drilling holes through both flat bars and then securing them together using the chosen fastener. Mechanical fasteners provide a strong joint and can be easily disassembled if needed. However, they may not provide the same level of strength as welding and may also be visible, depending on the chosen fastener. Adhesive bonding is another technique that can be used to join steel flat bars together. This involves using a high-strength adhesive specifically designed for metal bonding. The adhesive is applied to the contact surfaces of the flat bars, and then they are pressed together firmly until the adhesive cures. Adhesive bonding can provide a strong and aesthetically pleasing joint, but it may not be as strong as welding or mechanical fasteners in certain applications. Ultimately, the best method to join two steel flat bars together depends on the specific requirements of the project. It is recommended to consult with a professional or an experienced metalworker to determine the most suitable joining method for your particular needs.

- Q:Can steel flat bars be used in corrosive environments?

- Steel flat bars can be used in corrosive environments, but their performance will depend on the specific type of steel used and the severity of the corrosive environment. Some types of steel, such as stainless steel or weathering steel, have inherent corrosion resistance properties and are often used in applications where corrosion is a concern. These types of steel contain alloying elements that create a protective layer on the surface, preventing or slowing down the corrosion process. On the other hand, carbon steel flat bars are more susceptible to corrosion in corrosive environments. However, they can still be used with proper precautions. One common method is to apply a protective coating, such as paint or zinc galvanization, to create a barrier between the steel and the corrosive elements. Regular maintenance and inspection are also necessary to detect and address any signs of corrosion. In summary, steel flat bars can be used in corrosive environments, but the specific type of steel and the necessary protective measures should be considered to ensure their performance and longevity.

- Q:What are the weight and strength properties of steel flat bars?

- Steel flat bars are known for their high strength and durability. The weight of steel flat bars can vary depending on their dimensions, but they are generally heavier than other materials used for similar purposes. The strength properties of steel flat bars make them suitable for applications requiring load-bearing capacity and resistance to bending or deformation.

- Q:Can steel flat bars be used for manufacturing machine guards?

- Yes, steel flat bars can be used for manufacturing machine guards. Steel is a durable and strong material that provides excellent protection against impact and other potential hazards. Flat bars can be easily shaped and welded to create customized machine guards that meet the required safety specifications.

- Q:Can steel flat bars be coated with anti-slip materials?

- Yes, steel flat bars can be coated with anti-slip materials.

- Q:Can steel flat bars be used for staircases?

- Yes, steel flat bars can be used for staircases. Steel flat bars are commonly used in construction for various applications, including staircases. They are strong, durable, and can support heavy loads, making them suitable for staircase construction. Steel flat bars can be used as stringers, which are the main structural supports for the stairs, or as treads and risers, which are the steps themselves. They can be welded or bolted together to create a sturdy and stable staircase. Additionally, steel flat bars can be customized and fabricated to fit specific design requirements and dimensions, making them a versatile choice for staircase construction.

- Q:Can steel flat bars be used for making stair treads or steps?

- Yes, steel flat bars can be used for making stair treads or steps. Steel is a strong and durable material that can provide stability and support for staircases. Flat bars can be easily fabricated and shaped to create treads or steps that are both functional and aesthetically pleasing. Additionally, steel's resistance to corrosion makes it suitable for outdoor or high-traffic areas where stairs are commonly found. However, it is important to consider the thickness and dimensions of the steel flat bars to ensure they can withstand the expected load and meet the necessary safety standards.

- Q:What is the yield strength of a steel flat bar?

- The yield strength of a steel flat bar is the amount of stress or force it can bear before it permanently deforms. It is a significant mechanical property that indicates the maximum load the steel can handle without experiencing plastic deformation. The yield strength of a steel flat bar may differ based on the grade and type of steel used. Typically, common grades of steel used in flat bars have yield strengths ranging from 36,000 to 80,000 pounds per square inch (psi) or 250 to 550 megapascals (MPa). However, it's crucial to note that these values can vary and may depend on factors like the manufacturing process and any additional treatments or alloys used in the steel. Therefore, it is essential to refer to the specific specifications or testing data provided by the manufacturer or supplier to accurately determine the yield strength of a specific steel flat bar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Flat Bar Prime Low Carbon Metal Iron Flat by Slitted

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords