Steel Flat Bar Hot Rolled Retangular Section with Light Weight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Flat Bar Hot Rolled Retangular Section Description:

Steel flat bar hot rolled retangular section is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel flat bar hot rolled retangular section is usually made of structural steel and is used in construction and civil engineering. The steel flat bar hot rolled retangular section resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel flat bar hot rolled retangular section theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Flat Bar Hot Rolled Retangular Section:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

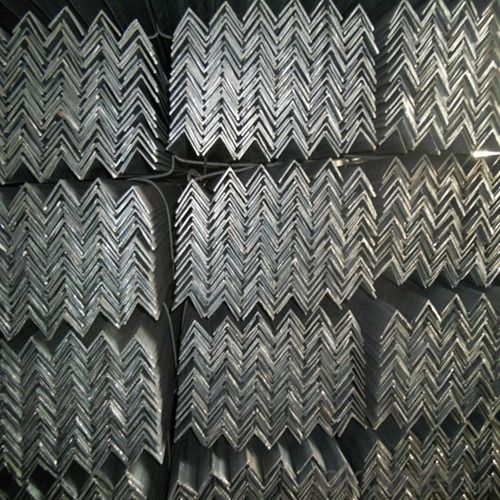

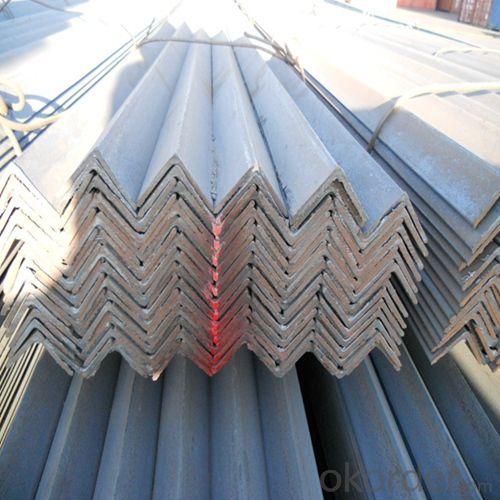

3. Steel Flat Bar Hot Rolled Retangular Section Images:

4. Steel Flat Bar Hot Rolled Retangular Section Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How do steel flat bars resist bending or twisting?

- Steel flat bars resist bending or twisting due to their inherent strength and rigidity. Steel is a strong and durable material that is able to withstand applied forces without easily deforming. The flat shape of the bar also contributes to its resistance to bending or twisting, as it distributes the forces evenly across its width. The resistance to bending or twisting of steel flat bars can be further enhanced by their cross-sectional shape. Most steel flat bars have a rectangular or square cross-section, which provides greater stability compared to other shapes. The flat surfaces of the bar help to distribute the bending or twisting forces evenly, preventing concentrated stress points that could lead to deformation. Additionally, the manufacturing process of steel flat bars involves heating the steel to a high temperature and then cooling it rapidly, a process known as quenching and tempering. This process increases the strength and toughness of the steel, making it more resistant to bending or twisting. Furthermore, the composition of the steel used in flat bars can also affect their resistance to bending or twisting. Alloying elements such as carbon, manganese, and chromium can be added to the steel to enhance its strength and resistance to deformation. Overall, the combination of the inherent strength and rigidity of steel, the flat shape of the bar, the cross-sectional design, and the manufacturing process contribute to the ability of steel flat bars to resist bending or twisting.

- Q:Are steel flat bars suitable for making furniture?

- Yes, steel flat bars are suitable for making furniture. Steel is a strong and durable material that can withstand heavy weight and provide stability to furniture pieces. Steel flat bars can be used to create various furniture items such as tables, chairs, shelves, and frames. They offer a sleek and modern aesthetic and can be easily incorporated into different design styles. Additionally, steel is resistant to rust and corrosion, making it a long-lasting and low-maintenance option for furniture. Overall, steel flat bars provide the necessary strength, stability, and versatility required for furniture making.

- Q:How do steel flat bars contribute to the overall flexibility of structures?

- Steel flat bars contribute to the overall flexibility of structures by providing strength, stability, and support. They can be easily bent, shaped, and welded into different configurations to accommodate the specific needs and design requirements of a structure. The flexibility of steel flat bars allows architects and engineers to create innovative designs and structures that can withstand various forces and loads, resulting in more efficient and adaptable buildings.

- Q:Are steel flat bars suitable for fabrication of frames or structures?

- Yes, steel flat bars are commonly used in the fabrication of frames or structures due to their high strength, durability, and versatility. They provide excellent support and stability, making them suitable for various applications in construction, manufacturing, and engineering industries.

- Q:What are the different types of surface treatments for steel flat bars?

- There are several different types of surface treatments available for steel flat bars, each serving a specific purpose and providing unique benefits. Some of the common surface treatments for steel flat bars include: 1. Hot-dip galvanizing: This process involves immersing the steel flat bar in a bath of molten zinc, which forms a protective layer on the surface. Hot-dip galvanizing provides excellent corrosion resistance and durability, making it suitable for outdoor applications. 2. Powder coating: Powder coating involves applying a dry powder to the steel flat bar's surface and then curing it with heat. This process creates a tough and durable finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and can enhance the aesthetic appeal of the steel flat bar. 3. Electroplating: Electroplating is a process where a thin layer of metal, such as chrome, nickel, or zinc, is deposited onto the steel flat bar's surface through an electrochemical reaction. This treatment improves corrosion resistance, enhances appearance, and can provide specific functional properties based on the chosen metal. 4. Paint coating: Applying a paint coating to the steel flat bar's surface provides both protection and aesthetics. Paint coatings can be customized to meet specific requirements and are available in various types such as epoxy, polyurethane, and acrylic. They offer good corrosion resistance and can be reapplied when necessary. 5. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to steel. The process involves creating an oxide layer on the surface of the steel flat bar through an electrolytic process. Anodizing enhances corrosion resistance and can be combined with coloring techniques to provide a decorative finish. 6. Phosphating: Phosphating is a chemical treatment that converts the steel flat bar's surface into a layer of phosphate crystals. This process improves corrosion resistance, provides an excellent base for subsequent coatings or paints, and enhances the adhesion of lubricants. 7. Shot blasting: Shot blasting is a mechanical surface treatment that involves propelling abrasive particles at high speeds onto the steel flat bar's surface. It removes impurities, rust, scale, and creates a textured finish, improving the adhesion of subsequent coatings. Each of these surface treatments offers distinct advantages and should be chosen based on the specific requirements of the steel flat bar's intended application, the desired appearance, and the level of corrosion resistance needed.

- Q:How are steel flat bars manufactured?

- Steel flat bars are manufactured through a process called hot rolling, which involves heating a steel billet to high temperatures and passing it through a series of rollers to achieve the desired dimensions and shape. This process helps in improving the strength and durability of the steel flat bars.

- Q:How do steel flat bars withstand heavy loads?

- Steel flat bars are specifically designed to withstand heavy loads due to their unique properties and construction. Firstly, steel is an incredibly strong and durable material. It has a high tensile strength, meaning it can withstand large amounts of force or pressure without breaking or deforming. This inherent strength makes steel flat bars an ideal choice for supporting heavy loads. Additionally, the flat shape of the bars provides increased stability and load-bearing capacity. The wide surface area of the flat bar allows for even distribution of the load, preventing concentrated stress points that could cause failure or deformation. Moreover, steel flat bars are often reinforced or tempered through various manufacturing processes. For example, they may be hot-rolled, which involves heating the steel to high temperatures and then rapidly cooling it to increase its strength and hardness. This process helps to further enhance the load-bearing capabilities of the flat bars. Furthermore, steel flat bars can be fabricated to meet specific load requirements. They can be cut, bent, or welded to create customized shapes and sizes that are optimized for the intended load. This versatility allows for the creation of structural elements that are specifically engineered to withstand heavy loads. Overall, the combination of steel's inherent strength, the wide surface area of the flat shape, reinforcement processes, and customization options make steel flat bars highly capable of withstanding heavy loads. They are a reliable and commonly used choice in construction, manufacturing, and other industries where robust load-bearing capabilities are necessary.

- Q:Can steel flat bars be used for manufacturing handrails or balustrades?

- Yes, steel flat bars can definitely be used for manufacturing handrails or balustrades. Steel flat bars offer a strong and durable material option for creating handrails and balustrades, as they have excellent structural integrity. They can be easily formed, welded, and shaped into the desired design, making them a versatile choice for manufacturing these elements. Steel flat bars also provide a sleek and modern aesthetic, adding a contemporary touch to any staircase or balcony. Additionally, steel is resistant to corrosion, making it a long-lasting and low-maintenance option for handrails and balustrades, particularly in outdoor or high-traffic areas. Overall, using steel flat bars for manufacturing handrails or balustrades is a practical and aesthetically pleasing choice.

- Q:Are steel flat bars suitable for machining processes?

- Yes, steel flat bars are suitable for machining processes. Steel flat bars are typically made from low-carbon steel, which is known for its excellent machinability. This means that it can be easily cut, drilled, and shaped using various machining techniques, such as milling, turning, or grinding. Additionally, steel is a durable and strong material, making it ideal for machining applications that require high precision and tight tolerances. However, it is important to note that the specific grade and composition of the steel flat bar may affect its machinability. Different grades of steel may have different hardness, toughness, and other properties, which can impact the machining process. Therefore, it is recommended to consult the manufacturer's guidelines or seek professional advice to ensure the suitability of steel flat bars for specific machining processes.

- Q:What are the properties of steel flat bars?

- Steel flat bars are rectangular-shaped bars made of steel, known for their versatility and strength. These bars have several properties that make them suitable for various applications. Firstly, steel flat bars have excellent tensile strength, which means they can withstand high levels of tension without breaking or deforming. This property makes them ideal for structural applications where strength and durability are crucial, such as in building construction and engineering projects. Another important property of steel flat bars is their ability to resist corrosion. Steel is typically alloyed with other elements, such as chromium or nickel, to enhance its corrosion resistance. This makes steel flat bars suitable for outdoor applications or in environments exposed to moisture, chemicals, or extreme temperatures. Steel flat bars also have good weldability, meaning they can be easily welded or joined together using various welding techniques. This property allows for the fabrication of complex structures or the reinforcement of existing ones, making steel flat bars a popular choice in the manufacturing and construction industries. In addition, steel flat bars have a high melting point, which makes them suitable for applications that involve exposure to high temperatures. They can withstand heat without losing their structural integrity, making them suitable for use in furnaces, ovens, or industrial machinery. Lastly, steel flat bars can be easily machined, cut, or shaped to meet specific requirements. This property allows for customization and versatility in various applications, including the manufacturing of machinery parts, brackets, frames, and supports. Overall, the properties of steel flat bars, including their strength, corrosion resistance, weldability, high melting point, and machinability, make them a versatile and reliable choice for a wide range of applications in numerous industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Flat Bar Hot Rolled Retangular Section with Light Weight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords