Steel Equal Angle with Good Quality 160mm*160mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications of Steel Equal Angle with Good Quality 160*160mm

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m and 12m

3. Sizes:

| Size(mm) | Mass(kg/m) | Size(mm) | Mass(kg/m) |

| 160*160*10 | 24.729 | 160*160*14 | 33.987 |

| 160*160*12 | 29.391 | 160*160*16 | 38.518 |

Packaging & Delivery of Steel Equal Angle with Good Quality 160*160mm:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

-Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

-Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 1 to 2 months.

Q4: How many tons per bundle?

A4: Around 2-3tons

Q5: How many tons can be loaded into one 20ft container?

A5: Around 23—25tons(6m)

Q6: How many tons can be loaded into one 40ft container?

A6: Around 23—25tons(12m)

Q7: How to avoid the rust after deliver the goods to the loading port?

A7: We will keep the goods at the port covered with water-proof material

Production flow of Steel Equal Angle with Good Quality 160*160mm:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

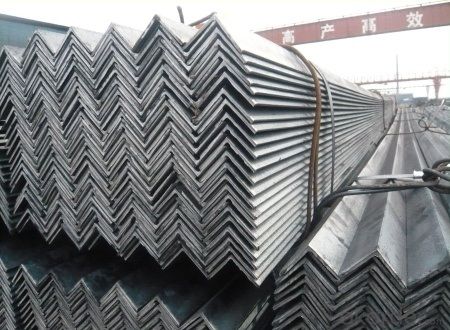

Images of Steel Equal Angle with Good Quality 160*160mm:

- Q:Can steel angles be used in the construction of religious institutions?

- Certainly, religious institutions can utilize steel angles in their construction projects. Given their strength, versatility, and durability, steel angles are widely employed in various construction endeavors. They not only provide structural support but can also be applied in framing, roofing, and reinforcing, among other applications. In the context of erecting religious institutions, steel angles can serve as the foundation for walls, roofs, and floors, while also lending support to architectural elements like domes or spires. Moreover, steel angles can be easily fabricated and tailored to meet specific design specifications. In summary, the use of steel angles in constructing religious institutions ensures the resilience and longevity of the edifice, while allowing for artistic ingenuity and adaptability.

- Q:What is the difference between hot-rolled and cold-rolled steel angles?

- Two distinct methods, hot-rolling and cold-rolling, are employed in the production of steel angles, resulting in varying characteristics. Hot-rolling involves heating a steel billet or ingot to a high temperature and subsequently passing it through a series of rollers. This process allows for the metal to be shaped and formed while it retains its malleability and pliability. Consequently, hot-rolled steel angles possess a coarser surface finish and less precise dimensions when compared to their cold-rolled counterparts. However, their strength and durability are generally superior, rendering them appropriate for structural applications necessitating high strength and load-bearing capacity. Conversely, cold-rolling entails passing hot-rolled steel through a sequence of rollers at room temperature. This procedure not only refines the dimensions and surface finish of the steel angles but also enhances their strength and hardness. Cold-rolled angles exhibit a smoother surface finish and more accurate dimensions, making them ideal for applications requiring precise fitting or a polished appearance. They are commonly employed in architectural and decorative endeavors, as well as in industries where aesthetics and precision are paramount. To summarize, the primary disparities between hot-rolled and cold-rolled steel angles lie in their manufacturing processes, surface finishes, dimensional accuracy, and applications. Hot-rolled angles are stronger and rougher, rendering them suitable for structural purposes, whereas cold-rolled angles possess a smoother finish and precise dimensions, making them more appropriate for decorative and architectural applications.

- Q:What is the thickness of the national standard 8# angle steel? Thank you

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm.

- Q:What are the limitations of using steel angles in highly corrosive or chemical environments?

- The use of steel angles in highly corrosive or chemical environments has certain limitations due to the nature of steel and its susceptibility to corrosion. Firstly, steel angles are primarily made from carbon steel, which is prone to rusting when exposed to moisture or chemicals. In highly corrosive environments, such as those containing acids, alkalis, or saltwater, the steel angles may corrode at an accelerated rate, leading to structural integrity issues. Moreover, steel angles may also suffer from pitting corrosion in such environments. Pitting corrosion occurs when small pits or holes form on the surface of the steel due to localized chemical reactions. This can weaken the angles and reduce their load-bearing capacity. Another limitation is that steel angles may not be resistant to specific chemicals or substances. Some chemicals can react with steel, causing degradation or even catastrophic failure. For instance, strong acids or bases can cause severe damage to the steel angles, leading to structural collapse. Furthermore, steel angles may require additional protective measures, such as coatings or corrosion inhibitors, to enhance their resistance in corrosive environments. These additional measures can add to the cost and maintenance requirements of the structure. In conclusion, while steel angles are widely used in various applications, their usage in highly corrosive or chemical environments has limitations due to their susceptibility to corrosion and potential chemical reactions. It is crucial to consider alternative materials or employ protective measures to ensure the structural integrity and longevity of the angles in such environments.

- Q:Can steel angles be used in the construction of power plants?

- Steel angles are indeed suitable for use in power plant construction. They are frequently employed to provide structural support and stability, as well as to withstand heavy loads. In power plant construction, steel angles have several applications, including framing structural components, supporting machinery, reinforcing concrete structures, and ensuring the overall structural integrity of the plant. Moreover, steel angles are highly resistant to corrosion, which is especially crucial in power plants where they are exposed to high temperatures, moisture, and chemicals. Thus, the versatility, strength, and durability of steel angles make them an excellent option for constructing power plants.

- Q:Can steel angles be used in earthquake-resistant building designs?

- Indeed, earthquake-resistant building designs can incorporate the usage of steel angles. Steel, renowned for its exceptional strength and ductility, proves to be a suitable material for constructing earthquake-resistant structures. In various applications, steel angles, also referred to as L-shaped steel sections, can be employed to provide structural support and reinforcement. One of the primary benefits of incorporating steel angles into earthquake-resistant building designs lies in their capacity to withstand lateral loads and shear forces. The L-shape of these steel angles establishes a robust and stable connection between distinct structural components, effectively distributing and transferring loads during seismic events. Consequently, this aids in mitigating structural deformation and averting collapse. Additionally, the fabrication and installation of steel angles are exceptionally convenient, rendering them a favorable choice for earthquake-resistant designs. These angles can be welded, bolted, or riveted to other steel elements, ensuring a sturdy and dependable connection. Furthermore, customization options are available, allowing for structural configurations to be tailored to meet specific design requirements. Furthermore, steel angles exhibit commendable fire resistance properties, a crucial aspect to consider in earthquake-resistant designs. Compared to other building materials, steel retains its structural integrity for an extended period in the event of a fire, thereby reducing the risk of collapse during rescue operations. To conclude, it is evident that steel angles can indeed be utilized in earthquake-resistant building designs. Their exceptional strength, ductility, and capability to withstand lateral loads make them an invaluable component in structural systems. By implementing appropriate design and installation techniques, steel angles can enhance the overall resilience and safety of buildings situated in earthquake-prone areas.

- Q:Are there any limitations on the length-to-thickness ratio of steel angles?

- Yes, there are limitations on the length-to-thickness ratio of steel angles. These limitations are specified in engineering codes and standards, which provide guidelines for the safe design and use of steel angles. The exact limitations depend on factors such as the material properties, intended application, and structural requirements.

- Q:What are the standard sizes of steel angles?

- The standard sizes of steel angles can vary depending on the region and industry, but there are some common sizes that are widely used. In general, steel angles come in equal leg and unequal leg sizes. For equal leg angles, the standard sizes range from 20x20mm to 200x200mm, with thicknesses ranging from 3mm to 26mm. Unequal leg angles typically have one leg longer than the other, and their standard sizes range from 25x16mm to 200x150mm, with thicknesses ranging from 3mm to 15mm. These standard sizes are commonly used in construction, engineering, and manufacturing industries for various applications, such as structural supports, framing, and bracing. It's important to note that these sizes may vary depending on the specific requirements of a project or the standards set by the governing bodies within the industry.

- Q:What is the maximum allowable lateral torsional buckling stress for a steel angle?

- The maximum stress that a steel angle can withstand before lateral torsional buckling occurs depends on several factors, including the angle's size, shape, material properties, and the design code being followed. To determine the maximum allowable stress for a steel angle, one can consider the critical moment of inertia and its corresponding critical stress. The critical moment of inertia measures the angle's ability to resist lateral torsional buckling and is affected by its geometry and dimensions. Design codes such as the AISC Manual of Steel Construction or the Eurocode provide specific values for the maximum allowable lateral torsional buckling stress. These codes offer guidelines and formulas for calculating this stress based on the angle's dimensions, material properties, and other factors like effective length and end conditions. To accurately determine the maximum allowable lateral torsional buckling stress for a particular steel angle, it is crucial to refer to the appropriate design code or standard and seek advice from a structural engineer or consult relevant reference materials.

- Q:Can steel angles be used for electrical conduits?

- No, steel angles cannot be used for electrical conduits as they are not designed or suitable for carrying electrical wiring. Electrical conduits are typically made of materials such as PVC, steel, or aluminum that are specifically designed to safely enclose and protect electrical wires.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Equal Angle with Good Quality 160mm*160mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords