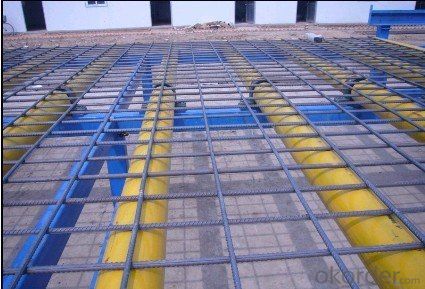

Steel concrete mesh / steel reinforcing welded wire mesh panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: steel bar

Weaving: the wires that run parallel to the width of the roll are placed on top of the wires running parallel to the length. Then, the wires are welded where they intersect.

Wire diameter: welded steel bar panels ranges from 5mm to 16mm.

Welded bar panels opening: 75mm to 300mm.

Panel length: 100cm to 1400cm.

Panel width: 100cm to 300cm.

Applications: Welded steel bar panels are widely used in construction reinforcement, the ground for the tunnels, bridges, highway, airport and wharf, also in construction of wall body.

Features: 1.It has a strong and firm body, can bear the high pressure from the concrete and exterior.

The reinforcing mesh can save much man-haur, reduce the material cost in the process.

2.The reinforcing mesh can design by the project requirement, improve the efficiency and

bond to the concrete can meet the special construct needs.

Packing: 1. Around with Angle steel welded into a bundle

2. Use steel bar tied into a bundle

3. 50-100pcs into a bundle

Special packing can be arranged upon request

- Q:Masonry works of different parts of the wall and slotted parts why to add steel wire mesh

- Wall), should be set before the stencil fine wire mesh (mesh width 400mm, along the interface joints on both sides of the extension of 200mm), or take other effective anti-cracking measures.

- Q:What are the maintenance requirements for steel wire mesh?

- The maintenance requirements for steel wire mesh typically involve regular cleaning to remove any dirt or debris that may accumulate on the surface. Additionally, it is important to inspect the mesh for any signs of damage or corrosion and address them promptly to prevent further deterioration. Periodic lubrication may also be necessary to ensure smooth operation, especially in cases where the mesh is used in a moving or mechanical application.

- Q:How long does steel wire mesh last?

- The lifespan of steel wire mesh can vary depending on various factors such as the quality of the material, the environment it is exposed to, and the level of maintenance it receives. However, in general, steel wire mesh is known for its durability and longevity. When properly installed and maintained, steel wire mesh can last for decades. It is resistant to corrosion, which is a common issue for other types of metal mesh. Additionally, steel wire mesh is highly robust and can withstand heavy loads and impacts without losing its structural integrity. The lifespan of steel wire mesh can be extended by implementing regular maintenance practices such as cleaning, inspecting for any signs of wear or damage, and repairing or replacing any affected areas promptly. Furthermore, using high-quality steel wire mesh and ensuring proper installation can significantly increase its longevity. In conclusion, steel wire mesh has a long lifespan and can provide reliable performance for many years when properly maintained.

- Q:What are the advantages and disadvantages of the bed of the steel mesh and the bed of the skeleton?

- Row of skeleton bed force to be much wider, and the intensity of the scattered out of each row of skeleton good can withstand 120KG force, is normal we stand alone, slam the two, is not

- Q:What are the different wire mesh ratios available in steel wire mesh?

- There are several different wire mesh ratios available in steel wire mesh, each serving different purposes and applications. The most common ratios include 2:2, 2:3, 2:4, and 3:3. The first number in the ratio represents the number of wires running horizontally per inch, while the second number represents the number of wires running vertically per inch. For example, a 2:2 wire mesh ratio means there are two horizontal wires and two vertical wires per inch. The choice of wire mesh ratio depends on the specific needs of the project. A 2:2 ratio is often used for general-purpose applications where a balance between strength and flexibility is required. This ratio is commonly found in fencing, screening, and light-duty applications. A 2:3 ratio, on the other hand, provides a higher level of strength and rigidity. It is often used in industrial applications such as machinery guards, security enclosures, and heavy-duty fencing. A 2:4 ratio offers even greater strength and stability, making it suitable for applications that require a high level of security, such as prison enclosures, animal cages, and reinforced barriers. Lastly, a 3:3 ratio is used in applications that require maximum strength and rigidity, such as concrete reinforcement, heavy-duty filtration, and structural support. It's important to note that these ratios are just a few examples, and there are many other wire mesh ratios available depending on the specific needs and requirements of a project.

- Q:What are the different wire mesh strengths available in steel wire mesh?

- There are various different wire mesh strengths available in steel wire mesh, which are determined by the thickness and type of wire used. Steel wire mesh is typically categorized into three main strength levels: light, medium, and heavy-duty. Light-duty steel wire mesh is commonly used for applications that require minimal strength, such as decorative purposes or lightweight fencing. It is usually made with thinner wires, typically ranging from 0.5mm to 1.2mm in diameter. Despite its lower strength, light-duty steel wire mesh still provides adequate support and durability for its intended uses. Medium-duty steel wire mesh offers a stronger option compared to light-duty mesh. It is commonly utilized in applications that require a moderate level of strength, such as security screens, animal enclosures, or reinforcement in concrete structures. The wire diameter for medium-duty mesh usually ranges from 1.2mm to 2.5mm, providing increased stability and resistance to deformation. For more demanding applications that require high strength and durability, heavy-duty steel wire mesh is the ideal choice. It is commonly used in industrial settings, construction projects, or areas with heavy loads or impacts. Heavy-duty mesh is made with thicker wires, typically ranging from 2.5mm to 6mm in diameter. This ensures exceptional strength, rigidity, and resistance to bending or breaking under intense pressure. It is important to note that wire mesh strength can also be influenced by factors such as the spacing between wires and the weave pattern used. Different configurations, such as square mesh or welded mesh, can affect the overall strength and performance of steel wire mesh. When selecting the appropriate wire mesh strength for a specific application, it is crucial to consider the intended purpose, expected load or pressure, and environmental conditions. Consulting with a knowledgeable supplier or expert can provide valuable guidance in choosing the right strength level to ensure optimal performance and longevity of the steel wire mesh.

- Q:Can steel wire mesh be used for ventilation or airflow control?

- Indeed, ventilation or airflow control can be achieved in certain applications through the utilization of steel wire mesh. This particular type of mesh finds widespread usage not only in HVAC systems but also in industrial settings and even in home ventilation systems. By permitting the passage of air while simultaneously obstructing the entry of larger particles or insects, it proves to be exceptionally suited for the regulation of airflow and the provision of ventilation. Moreover, steel wire mesh exhibits remarkable durability and can effectively endure high temperatures, rendering it highly suitable for deployment in environments where heat poses a concern. Nevertheless, it is imperative to thoroughly evaluate the specific requirements of the application at hand and ensure that the mesh size and design are aptly tailored to accomplish the desired level of airflow control.

- Q:How does steel wire mesh perform in terms of sound insulation?

- Steel wire mesh is not typically used for sound insulation purposes due to its inherent characteristics. Steel wire mesh is primarily used for industrial applications such as fencing, reinforcement in concrete structures, or filtration. It is not designed or known for its sound insulation properties. When it comes to sound insulation, materials with denser and thicker structures are preferred. Steel wire mesh, on the other hand, has an open and porous design, allowing sound waves to easily pass through it. This means that it does not provide significant sound absorption or reduction capabilities. If sound insulation is a priority, other materials such as acoustic panels, soundproof drywall, or specialized acoustic insulation products would be more suitable. These materials are specifically designed to absorb or block sound waves, offering better sound insulation performance compared to steel wire mesh.

- Q:What are the different types of coatings available for steel wire mesh?

- Steel wire mesh can be coated in various ways to enhance its properties and benefits. Here are a few options: 1. Galvanized Coating: The most commonly used coating for steel wire mesh is galvanized. This involves applying a layer of zinc to the mesh, protecting it from corrosion. Galvanized coatings come in two types: hot-dip galvanized and electro-galvanized. The former offers superior corrosion resistance. 2. PVC Coating: To provide extra protection and a pleasing finish, steel wire mesh can be coated with PVC (polyvinyl chloride). This involves applying a layer of PVC material to the mesh, preventing corrosion and providing a smooth appearance. PVC coatings are available in different colors to suit specific requirements. 3. Epoxy Coating: When chemical resistance is necessary, epoxy coatings are commonly used for steel wire mesh. These coatings adhere well and act as a protective barrier against corrosion, chemicals, and abrasion. Different epoxy formulations are available to suit various environmental conditions. 4. Polymer Coating: Polymer coatings, such as polyethylene and polypropylene, enhance the durability and corrosion resistance of steel wire mesh. These coatings are ideal for outdoor or marine environments where exposure to moisture and chemicals is common. Additionally, polymer coatings offer insulation properties and can resist UV damage. 5. Stainless Steel: In certain cases, stainless steel wire mesh is used instead of regular steel wire mesh. Stainless steel itself is corrosion-resistant, eliminating the need for additional coatings. It provides excellent durability and resistance to rust and corrosion, making it a popular choice for harsh environments. When selecting a coating for steel wire mesh, it is crucial to consider the specific application and environmental conditions. Each coating type offers distinct advantages, ensuring optimal performance and longevity of the wire mesh.

- Q:Is steel wire mesh resistant to alkalis or acids?

- Steel wire mesh is generally resistant to alkalis but is not resistant to acids. Alkalis are bases that have a pH greater than 7, and steel wire mesh is able to withstand the corrosive effects of these substances. However, acids, which have a pH lower than 7, can cause the steel wire mesh to corrode and deteriorate over time. Therefore, it is important to avoid exposing steel wire mesh to acids in order to maintain its integrity and durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel concrete mesh / steel reinforcing welded wire mesh panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords