Steel Billets and Steel Raw Materials Q235 Q275 Q345 New Design

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

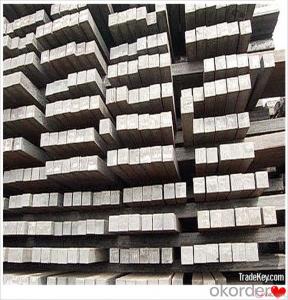

Steel Billets and Steel Raw Materials Q235 Q275 Q345 New Design

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q:What are the main factors affecting the thermal conductivity of steel billets?

- The main factors affecting the thermal conductivity of steel billets include the composition of the steel, its microstructure, temperature, and the presence of impurities or alloying elements.

- Q:What are the safety precautions to be taken while handling steel billets?

- When handling steel billets, there are several safety precautions that should be followed to ensure the well-being of individuals as well as the integrity of the material. Some key safety precautions include: 1. Personal Protective Equipment (PPE): It is essential to wear appropriate PPE such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Steel billets are heavy and can cause severe harm if dropped or mishandled. 2. Proper Lifting Techniques: When lifting steel billets, it is crucial to use proper lifting techniques, such as bending at the knees and keeping the back straight. This helps prevent strains, sprains, and other musculoskeletal injuries. 3. Adequate Training: Workers should receive proper training on how to handle steel billets safely. This includes understanding the weight and dimensions of the billets, knowing how to move them safely, and being aware of potential hazards. 4. Secure Storage and Transportation: Steel billets should be stored and transported in a secure manner to prevent accidents. They should be properly stacked, secured, and not overloaded to avoid falling or shifting during handling. 5. Clear Communication: In a work environment where multiple individuals are involved in handling steel billets, clear communication is essential. This includes using appropriate signals and verbal communication to coordinate movements and ensure everyone's safety. 6. Inspect Equipment: Before handling steel billets, it is important to inspect the equipment being used, such as cranes, forklifts, or other lifting devices. This helps identify any potential issues or malfunctions that could compromise safety. 7. Regular Maintenance: Regular maintenance of equipment used for handling steel billets is crucial to ensure their proper functioning. This includes inspections, repairs, and replacements as needed. 8. Hazard Identification: Workers should be trained to identify potential hazards associated with handling steel billets, such as sharp edges, hot surfaces, or slippery floors. Identifying and addressing these hazards promptly can prevent accidents and injuries. 9. Ergonomic Considerations: Ergonomic factors should be considered when designing workstations and handling procedures. This includes ensuring proper height and reach distances, providing adequate space for movement, and using tools or equipment that reduce strain on the body. 10. Emergency Response: Lastly, workers should be aware of emergency response procedures in case of accidents or injuries. This includes knowing the location of first aid kits, fire extinguishers, emergency exits, and how to report incidents to supervisors. By following these safety precautions, individuals can mitigate the risks associated with handling steel billets and create a safer work environment.

- Q:If the casting speed is not steady, what will happen to the billet?

- The instability of the casting speed leads to the unstable surface of the mould and increases the probability of slag entrapment in the mold.

- Q:How are steel billets used in the production of conveyor systems?

- Steel billets play a crucial role in the production of conveyor systems, as they are utilized to form the main structural framework. To achieve the desired shape, the billets undergo a process called hot rolling, which involves heating them and passing them through a series of rollers. This results in the transformation of the billets into long, slender bars with a consistent cross-sectional shape. Once shaped, the steel billets are further processed to create various components for the conveyor system. These components include conveyor frames, support beams, brackets, and other structural elements that provide stability and strength to the system. Steel billets are well-suited for this purpose due to their high tensile strength and durability. Apart from structural components, steel billets are also utilized in the production of conveyor rollers. These rollers are essential for facilitating the movement of materials along the conveyor system. The steel billets are machined and formed into cylindrical shapes, which are then fitted with bearings to ensure smooth rotation. The rollers are then installed at regular intervals along the conveyor, enabling efficient and continuous material handling. Furthermore, steel billets are often employed in the manufacturing of conveyor belts. The billets are processed into thin sheets, which are then coated with materials such as rubber or fabric to provide grip and durability. These belts bear the load of the materials being transported and are designed to withstand heavy usage and harsh environments. In conclusion, steel billets are vital in the production of conveyor systems, providing essential structural support as well as components like rollers and belts. Their strength, durability, and versatility make them an ideal choice for constructing conveyor systems that can handle heavy loads and ensure efficient material handling in various industries.

- Q:What are the different types of steel billet defect detection methods?

- There are several different types of steel billet defect detection methods that are commonly used in the industry. These methods help identify any defects or imperfections present in the steel billets, ensuring that only high-quality products are being produced. Some of the different types of steel billet defect detection methods include: 1. Visual Inspection: This is the most basic and common method, where trained inspectors visually examine the billets for any visible defects such as cracks, surface irregularities, or deformations. While effective for detecting certain types of defects, this method may not be able to identify internal or hidden defects. 2. Ultrasonic Testing: This method uses high-frequency sound waves to detect defects within the billets. Ultrasonic waves are passed through the billet, and any irregularities or disruptions in the waves indicate the presence of defects such as cracks or voids. Ultrasonic testing is a widely used technique for detecting internal defects. 3. Magnetic Particle Inspection: This method involves magnetizing the steel billet and then applying iron particles. If there are any surface or near-surface defects, the particles will be attracted to these areas, making the defects visible. Magnetic particle inspection is particularly effective for detecting surface cracks and discontinuities. 4. Eddy Current Testing: This technique uses electromagnetic induction to detect surface or near-surface defects in steel billets. A coil carrying an alternating current is placed near the billet, and any changes in the electrical conductivity or magnetic properties of the material caused by defects are detected. Eddy current testing is particularly useful for detecting surface cracks and corrosion. 5. X-ray Testing: X-ray inspection involves passing X-ray radiation through the steel billet and capturing the resulting image on a film or digital detector. Any internal defects such as cracks, voids, or inclusions will show up as dark spots on the X-ray image. X-ray testing is highly effective for detecting internal defects. 6. Laser Scanning: This method uses a laser scanner to create a three-dimensional image of the steel billet's surface. Any irregularities or deformations in the surface can be detected and analyzed using specialized software. Laser scanning is a precise and efficient method for detecting surface defects. These are just a few of the different types of steel billet defect detection methods that are commonly used in the industry. Each method has its own advantages and limitations, and the choice of method depends on factors such as the type of defect being targeted, the size and shape of the billets, and the level of precision required. By employing these defect detection methods, manufacturers can ensure the production of high-quality steel products.

- Q:What are the different methods of shaping steel billets?

- There are several methods of shaping steel billets, including hot rolling, cold rolling, forging, extrusion, and casting. Each method involves different techniques and processes to shape the steel billets into desired forms and dimensions.

- Q:How are steel billets used in the manufacturing of hydraulic equipment?

- Steel billets are commonly used in the manufacturing of hydraulic equipment as they serve as the raw material for creating various components, such as cylinders, valves, and pistons. These billets are heated and then shaped through forging or extrusion processes to form the desired hydraulic equipment parts. The strength, durability, and versatility of steel make it a preferred material choice for hydraulic equipment, enabling it to withstand the high pressures and demanding working conditions in this industry.

- Q:What is a steel billet?

- A steel billet is a semi-finished product that is created through the process of casting molten steel into a rectangular shape. It typically has a square or rectangular cross-section and is often used as a starting material for various steel products. The size of a steel billet can vary depending on its intended use, but it is typically around 100mm to 200mm square in cross-section and several meters long. Once produced, steel billets are further processed through rolling or extrusion to create different shapes such as bars, rods, wires, or structural steel sections. Steel billets are widely used in the manufacturing industry as a raw material for the production of a wide range of steel products used in construction, automotive, machinery, and many other sectors.

- Q:What are the properties of alloy steel billets?

- Alloy steel billets possess a combination of properties that make them highly desirable for various applications. These properties include high strength, excellent hardness and wear resistance, good toughness, and improved corrosion resistance compared to carbon steel. Additionally, alloy steel billets have the ability to withstand high temperatures and exhibit excellent machinability, making them ideal for use in industries such as automotive, aerospace, construction, and manufacturing.

- Q:How do steel billets contribute to the fire resistance of a structure?

- The fire resistance of a structure is primarily enhanced by the presence of steel billets, which possess a high melting point and the ability to conduct heat effectively. Unlike wood or concrete, steel has a considerably higher melting point, ranging from 1370 to 1538 degrees Celsius (2500 to 2800 degrees Fahrenheit). The high melting point of steel billets allows them to withstand intense heat without compromising their structural integrity during a fire. Consequently, the steel framework of a building remains intact even when exposed to elevated temperatures, reducing the likelihood of warping, softening, or collapse. Moreover, steel's excellent heat conductivity enables it to rapidly absorb heat and transfer it away from the affected area when exposed to fire. This characteristic prevents the fire from spreading and limits the damage inflicted upon the structure. Additionally, the heat dissipation property of steel helps prevent the transmission of heat to non-steel components like walls or floors, thereby impeding the fire's rapid propagation. Furthermore, steel billets possess a low thermal expansion coefficient, meaning that their expansion rate is comparatively slow when subjected to extreme heat. This attribute prevents excessive movement or deformation of the steel structure during a fire, ensuring the maintenance of stability and structural integrity. In conclusion, steel billets play a vital role in enhancing the fire resistance of a structure by offering high heat resistance, efficient heat conduction, and minimal thermal expansion. These properties render steel an ideal choice for constructing fire-resistant buildings, ensuring increased safety for occupants and reducing the risk of total or partial collapse in the event of a fire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Billets and Steel Raw Materials Q235 Q275 Q345 New Design

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords