Steel Billet For Sale Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet For Sale Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

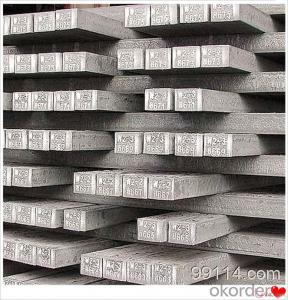

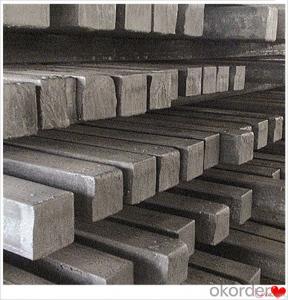

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q:Can steel billets be used in the automotive industry?

- Yes, steel billets can be used in the automotive industry. They are commonly used as raw materials for manufacturing various automotive components such as engine blocks, transmission gears, axles, and suspension parts. The high strength and durability of steel make it an ideal choice for ensuring the safety and performance of vehicles.

- Q:How are steel billets used in the manufacturing of shipbuilding components?

- The manufacturing of shipbuilding components relies heavily on steel billets, which are indispensable raw materials. These components, including hulls, decks, bulkheads, and other structural parts, are crucial for ship construction. To begin the process, steel billets are heated in a furnace to a specific temperature, rendering them malleable. This crucial step, known as hot rolling, allows the billets to be shaped into the desired forms and sizes required for shipbuilding components. In addition to shaping, hot rolling also enhances the mechanical properties of the steel, making it stronger and more durable. Once the billets are heated and shaped, they undergo further processing through various techniques such as forging, extrusion, or casting, depending on the specific shipbuilding components needed. For instance, steel billets can be forged to create large and intricate parts like ship propellers or rudders. Extrusion, on the other hand, is employed to form long and continuous shapes like shipbuilding beams or pipes. Casting is utilized for intricate components such as engine parts or valves. Following the initial shaping process, the steel components go through various finishing operations including machining, welding, and surface treatment. Machining ensures the achievement of precise dimensions and smooth surfaces necessary for the proper fitting and functioning of shipbuilding components. Welding is employed to join different steel components together, ensuring structural integrity and strength. Surface treatment techniques such as painting or galvanizing are applied to protect the components from corrosion and extend their lifespan. Overall, steel billets are of utmost importance in shipbuilding as they serve as the essential raw material for manufacturing a wide range of components. Their versatility, strength, and durability make them ideal for constructing ships that can withstand the harsh marine environment. By utilizing steel billets along with advanced manufacturing techniques, high-quality shipbuilding components that adhere to stringent industry standards can be produced.

- Q:What are the different types of non-destructive testing methods used for steel billets?

- There are several different types of non-destructive testing methods used for steel billets. These methods are employed to ensure the quality and integrity of the billets without causing any damage or alteration to the material. Some of the commonly used non-destructive testing methods for steel billets include: 1. Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect internal defects or inconsistencies within the steel billets. UT can identify issues like cracks, voids, and inclusions that may affect the billet's strength and performance. 2. Magnetic Particle Testing (MPT): MPT involves the use of magnetic fields and magnetic particles to detect surface and near-surface defects in the steel billets. This method is particularly effective for identifying cracks, seams, and other discontinuities that may not be visible to the naked eye. 3. Eddy Current Testing (ECT): ECT utilizes electromagnetic induction to assess the quality of steel billets. It can detect surface and near-surface defects, such as cracks and corrosion, by measuring changes in electrical conductivity and magnetic fields. 4. Visual Inspection: Visual inspection is a basic non-destructive testing method that involves a thorough visual examination of the steel billets. It aims to identify any visible defects, such as surface cracks, dents, or irregularities in shape or size. 5. Penetrant Testing (PT): PT involves applying a liquid or fluorescent dye to the surface of the steel billets. The dye seeps into any surface defects, and after a certain time, excess dye is removed, and a developer is applied to make the defects visible. This method is useful for detecting surface cracks, porosity, and other surface irregularities. 6. Radiographic Testing (RT): RT uses X-rays or gamma rays to penetrate the steel billets and produce an image that can reveal internal defects. This method is highly effective for detecting cracks, inclusions, and voids within the billets. Each of these non-destructive testing methods plays a crucial role in ensuring the quality and reliability of steel billets. By employing a combination of these techniques, manufacturers can identify any potential defects or inconsistencies and take appropriate measures to rectify them, thereby ensuring the safety and performance of the steel billets in various applications.

- Q:What are the common sizes and dimensions of steel billets?

- Steel billets are produced through continuous casting or hot rolling methods and are semi-finished products. The industry and intended use of the billets determine their sizes and dimensions. While there are common sizes and dimensions used in various applications, they can vary. The size range for steel billets is typically between 100mm and 150mm square. These billets are usually around 6 meters long, but this may differ based on customer needs or the manufacturing process. Round steel billets with diameters ranging from 100mm to 200mm are also commonly produced. The weight of steel billets can range from a few hundred kilograms to several metric tons. The length, cross-sectional area, and density of the steel used determine the weight. Most steel billets fall within the 1 to 5 metric tons range. It is important to understand that these sizes and dimensions can differ among manufacturers, and different industries may have specific requirements. For instance, the automotive industry may require larger or smaller billets based on the parts they produce. In conclusion, steel billets typically have sizes and dimensions between 100mm and 150mm square, with lengths of around 6 meters. Round billets can have diameters ranging from 100mm to 200mm. The weight of a steel billet can vary from a few hundred kilograms to several metric tons. However, it is crucial to consider that these measurements can vary depending on the industry and customer requirements.

- Q:How are steel billets used in the manufacturing of machinery and equipment?

- Steel billets are used in the manufacturing of machinery and equipment as they serve as the primary raw material for creating various components such as gears, shafts, and structural frames. These billets are heated and subjected to a series of shaping processes, such as rolling, forging, and machining, to form the desired shape and size of the machinery parts. The strength, durability, and versatility of steel make it an ideal choice for producing robust and reliable machinery and equipment.

- Q:How are steel billets used in the manufacturing of slabs?

- Steel billets are an essential raw material used in the manufacturing of slabs. Slabs are large, flat pieces of steel that are used as a primary input in various industries, such as construction, automotive, and manufacturing. To produce slabs, the first step involves obtaining steel billets. These billets are semi-finished steel products that are typically obtained through the continuous casting process or by hot-rolling ingots. They are solid, rectangular or square-shaped blocks of steel with a cross-sectional area that can vary depending on the desired size and thickness of the slabs. Once the steel billets are obtained, they are heated to a high temperature to make them more malleable and easier to shape. This process, known as hot rolling, involves passing the billets through a series of rolling mills to progressively reduce their thickness and increase their length. The rolling mills apply intense pressure to the billets, causing them to elongate and acquire the desired dimensions. During the hot rolling process, the steel billets are often subjected to various manipulations, such as reheating and cooling, to ensure proper shaping and metallurgical properties. The billets may also go through additional processes, such as descaling (removing the oxide layer) and surface treatment, to enhance their quality and finish. Once the hot rolling process is completed, the steel billets are transformed into slabs. These slabs are then further processed to meet specific requirements. For instance, they may undergo additional rolling or reheating processes to achieve the desired thickness, dimensions, and surface finish. The slabs can also be cut into smaller pieces or further processed into different steel products, such as plates, sheets, or coils, depending on the intended use. In summary, steel billets play a crucial role in the manufacturing of slabs. They serve as the starting point for the production process, undergoing hot rolling and other treatments to transform them into the desired shape, size, and quality. The resulting slabs are then used as a primary input in various industries, contributing to the production of a wide range of steel products.

- Q:What are the different types of steel billet inspection techniques?

- There are several types of steel billet inspection techniques, including visual inspection, ultrasonic testing, magnetic particle testing, dye penetrant testing, and eddy current testing.

- Q:What are the potential applications of steel billets in the oil and gas industry?

- The oil and gas industry can utilize steel billets in a wide range of ways. These include, but are not limited to, the following: 1. Manufacturing pipes: Steel billets can be used to create pipes that are crucial for transporting oil and gas. The strength and durability of steel make it an excellent choice for constructing pipes that can withstand the harsh conditions of drilling, extraction, and transportation. 2. Creating drill collars: Steel billets can be machined into drill collars, which are heavy steel tubes used in drilling. Drill collars provide weight to the drill string, increasing the force applied to the drill bit. The strength and toughness of steel billets make them suitable for this application, as they can withstand the high torque and pressure exerted during drilling. 3. Making downhole tools: Steel billets can also be used to manufacture a variety of downhole tools used in oil and gas exploration, including stabilizers, reamers, and subs. These tools are crucial for maintaining wellbore stability, clearing obstructions, and enhancing drilling efficiency. The ability of steel billets to withstand high temperatures, pressures, and abrasive environments makes them suitable for these tools. 4. Constructing offshore structures: Steel billets can be used in the construction of offshore platforms, jackets, and other structural components. These structures must withstand extreme weather conditions, corrosive environments, and heavy loads. Steel billets, with their high strength, corrosion resistance, and weldability, are an ideal choice for such applications. 5. Machining equipment and machinery components: Steel billets can be machined into various components and parts for oil and gas equipment and machinery. This includes valves, fittings, flanges, connectors, and other critical components used in drilling rigs, pipelines, refineries, and processing facilities. The versatility and reliability of steel make it a preferred material for such applications. In summary, steel billets have a wide range of potential applications in the oil and gas industry. Their high strength, durability, corrosion resistance, and versatility make them essential in pipe manufacturing, the creation of drill collars and downhole tools, the construction of offshore structures, and the machining of equipment components. Steel billets play a crucial role in ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q:How do steel billets contribute to the manufacturing of consumer electronics?

- Steel billets are an essential component in the manufacturing of consumer electronics due to their versatile properties and durability. These billets are essentially semi-finished steel products that are hot-rolled into various shapes and sizes, making them suitable for a wide range of applications. One of the main ways steel billets contribute to the manufacturing of consumer electronics is through the production of casings and structural components. Steel is known for its strength and rigidity, which makes it ideal for providing structural support and protection to electronic devices. Whether it is mobile phones, laptops, or gaming consoles, steel billets are used to create the outer casings that safeguard the internal components from damage. Additionally, steel billets are also utilized in the production of connectors and terminals found in consumer electronics. These small but crucial parts enable the flow of electricity between different components and ensure the smooth functioning of electronic devices. Steel's excellent electrical conductivity and resistance to corrosion make it a reliable material for these connectors, ensuring optimal performance and longevity of the electronic devices. Furthermore, steel billets contribute to the manufacturing of consumer electronics by being used in the fabrication of heat sinks. Heat sinks are essential in electronic devices to dissipate excess heat generated by the components, preventing overheating and potential damage. Steel's thermal conductivity and heat resistance properties make it an ideal material for these heat sinks, effectively transferring heat away from critical components and ensuring the reliability and longevity of the electronic devices. In conclusion, steel billets play a significant role in the manufacturing of consumer electronics by providing the necessary strength, durability, and thermal conductivity required for various applications. Whether it is in the production of casings, connectors, or heat sinks, steel billets contribute to the overall quality and functionality of electronic devices, ensuring a seamless user experience.

- Q:How are steel billets cleaned before further processing?

- Steel billets are cleaned before further processing through a series of steps to remove any impurities or contaminants. The cleaning process starts with the billets being subjected to a high-pressure water jet to remove any loose scale or dirt on the surface. This water jetting helps in removing most of the loose particles and provides a clean surface for further cleaning. After the initial water jetting, the billets are then immersed in an acid bath. The acid bath can be a mixture of different chemicals like hydrochloric acid, sulfuric acid, or a combination of both. The acid bath helps in removing any remaining scale or oxide layers on the surface of the billets. The acid reacts with these impurities, dissolving them and leaving a clean surface behind. Once the acid cleaning is complete, the billets are rinsed thoroughly with water to remove any traces of the acid. This rinsing process is crucial to ensure that no acid residue remains on the surface, as it could potentially affect the quality of the final product. After rinsing, the billets are then dried using hot air or in a furnace to remove any moisture. This drying process is necessary to prevent any rusting or corrosion from occurring on the surface of the billets. Overall, the cleaning of steel billets before further processing is a crucial step in ensuring the quality and integrity of the final product. It helps in removing impurities, scale, and oxide layers from the surface, providing a clean and uniform surface for subsequent processing operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Billet For Sale Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords