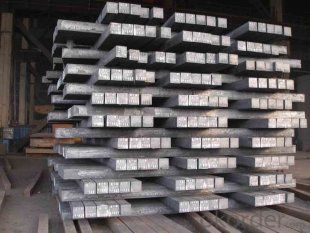

Steel Billet for Basic Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description

Mainly from the shape is divided into two kinds:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod.,

2. Main Features

Billet was rolled steel, after processing can be used for mechanical parts, forging parts, processing all kinds of steel, steel Q345B channel steel, wire rod is the role of the billet.

3. Excellent Product Image

4. Application

Steel billet is used in the production of semi-finished products, generally cannot be used directly for the society.Steel billets and steel are strictly divided into standard, cannot decide to whether the business enterprise of the final product, and according to unified standards to perform the whole society.Typically, billet and the steel is relatively easy to distinguish, but for some steel billet, and have the same specification and same steel purposes (such as rolling tube billet), whether can be used for other industries, whether through steel processing process, whether through a finished product rolling mill processing to distinguish.

5. FAQ

1.Q: Do you have attended any exhibition?

A: We almost go to Canton Fair and Overseas Exhibitions every year.

2. Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. Q: How long can we receive the product after purchase?

A: Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

Why choose us?

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trust-worthy sales team.

6. We have 18 years' experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. Count the most efficient shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment.

3. Email you the tracking no, and help to chase the parcels until it arrive you.

- Q:What are the raw materials and production processes of steel?

- Steel (Steel): material of various shapes, sizes, and properties required by pressure processing for ingots, billets, or steels.

- Q:What are the standards for cold rolling and hot rolling of stainless steel? What's the difference?

- The free torsion rigidity of hot rolled steel is higher than that of cold rolled steel, so the torsion resistance of hot rolled steel is better than that of cold rolled steel.

- Q:What's the difference between a cold plate and a hot plate?

- Hair straightenerrollhead, tail tongue shapeand thefishtail shape, thickness, width of poor accuracy, edgehaswavy, folding, tower and other defects. The coil weight is heavy, and the inner diameter of the steel coil is 760mm. (general management industry likes to use. Thestraightthroughcutting) cutting head, tail cutting, trimming and multipass straightening and leveling finishing line processing, cutting board or heavy volume, which becomes: hot rolled steel plate and flat steel coils, slittingstripand other products. Hot finishing rolling by pickling descaling and oil is made by pickling hot-rolled coils. This product has the tendency to replace the cold rolled plate locally, the price is moderate, and is well liked by the customers.

- Q:Stainless steel composite process

- In general, there are three kinds of stainless steel clad plate production methods: direct rolling stainless steel composite plate (also known as pressure welding or solid phase welding), explosive composite method and explosive welding rolling synthesis technology. Composite plate with different thickness and different ratio, different varieties, different specifications and different requirements, respectively, using the three kinds of processing technology, classification of production, varieties and specifications of the composite board is greatly increased, product appearance, reliable quality, can meet a variety of different users, different industries, different environment and different conditions of use requirements.

- Q:What's the difference between stainless steel strip 304 hot rolling and cold rolling?

- The cold rolled plate is mainly made of thin plate and rolled by plate at room temperature. Usually, subsequent surfaces are subjected to pickling, polishing, and passivation. The price at the factory level, of course, is expensive for cold rolling

- Q:How to recognize the raw plate in the steel plate?

- Steel plate called "cooked", probably "cold plate" and "hot plate" points, cold plate is cold-rolled steel short.

- Q:What kind of steel is Q2351?

- The molten steel produced by a steel furnace is cast into billets, ingots or billets, which are processed into steel (steel products) by pressure. There are many kinds of steel, which can be divided into four categories: type, plate, tube and wire.1, steel types of many types of steel, is a certain cross-section shape and size of solid long strip steel. It is divided into two kinds of simple and complex sections according to their cross section shapes. The former includes round steel, Fang Gang, flat steel, six angles and angles; the latter include rail, I-beam, channel steel, window frame steel and profiled steel. Round steel of 6.5 -9.0mm in diameter is called wire rod.2, steel plate typeIt is a kind of flat steel with big width ratio and large surface area. According to the thickness of different thickness of sheet (thickness < 4mm), medium plate (thickness 4 -25mm) and thick plate (thickness > 25mm) three kinds. The steel strip is included in the steel plate.

- Q:Stamping process classification

- Deep drawing: drawing is also called drawing or rolling. It is the punching process of hollow parts made of flat blank made by blanking. The drawing process can be used to make cylindrical, stepped, tapered, spherical, box shaped and other irregularly shaped thin-walled parts. In addition to other stamping processes, parts with extremely complex shapes can be made. In stamping production, there are many kinds of drawing parts. Because of its different geometry characteristics, the location of deformation zone, the nature of deformation, the distribution of deformation and the stress state and distribution law of each part of the blank have considerable or even essential differences. Therefore, the process parameters, the number of processes and the order of determination methods and die design principles and methods are not the same. According to the characteristics of deformation mechanics, all kinds of drawing parts can be divided into four types: straight wall revolving body (cylindrical part), straight wall non rotating body (box shape), curved surface revolving body (curved surface shape part) and curved surface non revolving body.

- Q:What is a metal layered composite?

- Explosion composite methodExplosive composite method is to use the huge energy produced by explosive as energy to make the metal surface deformation, melting and diffusion, so as to realize the welding of dissimilar metals.The utility model is mainly applicable to the production of composite sheet products or composite slabs and multiple composite boards with larger sheet thickness and larger sheet area.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Billet for Basic Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords