Steel bar truss floor deck

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

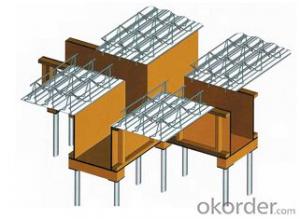

DUOWEI steel bar truss floor deck is the integrated fabricated formwork for which steel bar is to be processed into steel bar truss and then the steel bar truss is to be welded with galvanized profiled sheet. In the construction stage, the steel bar truss floor deck can bear the construction load; moreover, concrete can be poured after steel bars are directly laid on the beam for simple steel bar works. As form functions can be completely replaced, form erection and removal works can be reduced, so floor slab construction efficiency can be greatly improved.

DUOWEI steel bar truss floor deck has features such as economy, convenience, safety and reliability, etc and it has been widely used by structure and building fields such as multilayer workshops, multilayer, high-rise and ultra-high steel structure buildings and various irregular floors, concrete structures and high speed railway, etc.

1. Unique double folding design

Effectively increase board edge strength; hard to bend or deform during transportation and construction;

Ensure edge straightness of product, fastening of bottom form gets easier;

Improve compactness of bottom form lapping, effectively prevent leakage;

Improve construction quality and protect customer’s interests.

2. Improved form spot welding technology

Original form spot welding equipments are improved to make welding current of many welding heads more balanced and stable, so the floor deck to be made will be free from cold joint or weld penetration phenomenon.

Four advantages

Economic

The load-bearing mode of the truss is reasonable, the consumed materials economic, and the advantage of integrated costs obvious.

It can be designed into two-way slab, with adjustable truss height and diameter of reinforcement, intended to apply to the floor slab of larger span.

Convenient

The field steel binding quantity is reduced by 60% - 70%, and the construction period is further shortened.

The load-bearing mode of the truss is reasonable, which can provide greater stiffness to floor beating slab, greatly reducing or even sparing the use of temporary bracing.

Safe

The mechanical property is basically the same as the traditional floor slab, with good crack resistance.

The fire-resistant performance is equal to the traditional floor slab, superior to the profiled steel plate composite slab.

The bottom die is not loaded in the use phase, eliminating the consideration to fire and corrosion problems.

Reliable

The reinforcements are arranged uniformly, and the spacing between two layers of reinforcements and the thickness of concrete cover are reliably guaranteed.

The two-way stiffnesses of the floor slabs are similar, conducive to the seismic stud welding, so the quality is easier to ensure.

- Q:How is the stone sheet transported?

- Stone sheet should be erected when transported by the fixed side of the compartment.

- Q:What is a lightweight sheet?

- Lightweight sheet is made of inorganic cementitious material as the main matrix material, using a variety of prefabricated process, the length and width is much larger than the thickness of the plate density or surface density and ordinary concrete products compared to low building products.

- Q:Now home furnishings are what plate?

- Blockboard blockboard, line known as big core board. Daxing board is made of two pieces of veneer stamping together. Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength is higher.

- Q:Imitation marble pvc plate 1.5 thick

- 1, the process: the substrate is a mixture of calcium powder and PVC after a squeeze molding. Surface by thermal transfer process vacuum embossed imitation marble pattern, do uv fluorocarbon varnish. Imitation marble glass magnesium board, the substrate is glass magnesium board, alumina calcium oxide mixed material. Surface stickers are coated with marble. 2, specifications: uv imitation marble sheet general specifications is a single sheet 1200 * 2400mm, thickness of 3.8-4mm. Weight is generally between 21.5-23 kg. Imitation marble glass magnesium board leaflets specifications are generally 1200 * 2400mm, thickness of 5mm, the weight is generally about 30 kg. 3, features: a natural marble effect, clear lines, simulation results as high as 99.5% or more. Color uniformity, smooth surface, wear, hardness up to 5H-7H, easy to clean, resistant to pollution, B1 fire, no radiation, light weight, weight is one-fifth of natural marble, the price is. 4, use: instead of natural marble, widely used in a variety of architectural interior decoration. Hotels, office buildings, shopping malls, supermarkets, KTV, bars, cinemas, hot springs clubs, offices. Home improvement is mainly used for film and television background wall, sofa background wall, all kinds of Pass.

- Q:Will 304 stainless steel and 301 stainless steel What is the difference?

- 1, specifications: commonly used stainless steel sheet is divided into 201 and 304 two models, the actual composition is different, 304 quality better, but the price is expensive, 201 worse. 304 for the import of stainless steel, 201 for the domestic stainless steel plate. 2, 201 composition of 17Cr-4.5Ni-6Mn-N, is the section of Ni steel, 301 steel alternative steel. After cold processing with magnetic, for railway vehicles. 3, 304 composition of 18Cr-9Ni, is the most widely used stainless steel, heat-resistant steel. For food production equipment, the former chemical equipment, nuclear energy and so on. 4, 201 is a high manganese content, the surface is very bright with dark black, high manganese content is easy to rust. 304 chrome more, the surface showing matte, no rust. Two put together there is a comparison. The most important thing is the corrosion resistance of different, 201 corrosion resistance is poor, so the price will be much cheaper. And because 201 nickel low, so the price is lower than 304, so corrosion resistance is not as good as 304. 5, 201 and 304 is the difference between the nickel-containing problem. And the price of 304 are now more expensive, generally close to 50000 a ton, but at least 304 can guarantee that the use of the process will not rust. (Can be used to do the experiment) 6, stainless steel is not easy to rust because the surface of the steel body to form chromium-rich oxide can protect the body, 201 material is high manganese stainless steel 304 hardness higher carbon low nickel. 7, the composition of different (mainly from carbon, manganese, nickel, chromium and other aspects to distinguish between 201 and 304 stainless steel) Steel (C) silicon (Si) manganese (Mn) phosphorus (P) sulfur (S) chromium (Cr) nickel (Ni) molybdenum (Mo) copper (Cu) AISI (304) ≤0.08 ≤1.00 ≤2.00 ≤0.045 ≤0.03 18-20 8-10 AISI (201) ≤0.15 ≤1.00 5.5-7.5 ≤0.05 ≤0.03 16-18 3.5-5.5

- Q:Bunny plate prices and Moganshan plate which is of good quality, expensive?

- The two almost, but I tend to king coconut plate, although he is also the top ten brands of plates, but the king coconut of the paint plate is the national standard drafting unit

- Q:In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- 1, if the nose is a metal support, you can hand to the middle of breaking off. 2, if the whole into a whole is plastic, nasal care will not be deformed. It must be attached to the lens and the lens between the screws too loose, two mirror feet breaking too open, you can tighten the screw tight. But the screw is very small, it is recommended to the optical shop told him to help you twisted. Adjust the cleaning and repair nose care such things all stores will do for you free of charge. You can go to your original optical shop, but casually a RP shop staff will be happy to help you tune and clean up.

- Q:There are usually several kinds of plates

- Cabinet box board usually has three kinds of materials: (1) Blockboard (2) Particleboard (3) medium density fiberboard And the surface layer of the board used in the cabinet cabinet is treated with trihydroxyammonium refractory veneer. Box thickness 18mm. (Avoid using 16mm, so as not to bend deformation, in the purchase of cabinets, please pay special attention). Blockboard wood core is made of natural wood sticks, the waterproof and moisture resistance is better than the particleboard and MDF. Because it is natural wood, so fast, easy assembly and easy to loose. In view of the blockboard is made of wood. Therefore, the surface roughness is often poor, often appear ribs block, for the cabinet cabinet board, the visual level of the feeling of uneven. Therefore, the cabinet company is not unreasonable to abandon. Such as blockboard to solve the uneven shortcomings, can be described as the ideal selection. Particleboard is fundamentally different from the traditional concept of particleboard. As a result of the use of German machinery, molecular shrinking more closely, so it can be load-bearing, and not easy to bend deformation. Particleboard is natural wood crushed into granular, the pressed into a plate, the waterproof performance is better than the MDF, cabinet cabinet is the main material. Which made the Jilin Lu Shui River board for the best, but there are many fake on the market, we must pay attention to the time to buy identification. Medium density board is powder after molding, resistance to wet performance is poor. Flatness is better, usually used for plate furniture, office furniture more. As the MDF tightening after easy loose, loose and then tightening strength. Therefore, the cabinet company has no more general use of some truth. Due to the medium density flatness, for the door and the countertop more appropriate. For the cabinet board, in the assembly fastening process, subject to certain limitations.

- Q:Will the sheet metal processing bending coefficient and plate thickness, bending angle, bending radius is what is the relationship between the urgent!

- The bending factor and the thickness of the material you said bending angle ah bend the radius and bending the bending machine up and down mold, the length of the bending parts are related We are using experience value. After all, conventional standard brick algorithm does not take into account the equipment wear and tear, sheet material thickness of the situation Different thickness determines the different bending factors such as 1mm cold rolling fold 90 degrees and 2mm cold rolling fold 90 degrees Our actual situation is 1mm coefficient is 1.8 2mm coefficient is 3.5 The same angle 90 degrees is a bending factor of 60 degrees is 1/2 of the bending coefficient of 45 degrees is 1/3 of the bending coefficient of less than 30 degrees according to the different thickness of the buckle or buckle a 0.5 Material and plate thickness as different materials, the bending coefficient is different The bending radius is related to the bending machine. The standard single V or double V is even the default value of the other V slots. But there are customers who need to be too small or a large bend radius will be specific to the analysis Too small bend radius, our approach is to plan the groove to bend, so that the bending radius is very small, almost vertical right angle bending Too large bending radius, the upper mold can be used on the corresponding arc on the mold (note that the upper arc of the R is the inside of your bending R, if the outside R according to the outer R minus a plate thickness to determine the model) Or a large R30 50 or more, you can use a split bend, which requires the calculation of the cut-in angle and the last knife angle, as well as the size and angle of each knife There is a part of the length of this I think a lot or machine equipment and related to our machine a long time 1.5mm stainless steel over 1m according to the case will not use 8mm mold bending

- Q:How to introduce plate-type furniture plate?

- Furniture: solid wood furniture and sheet metal furniture. Soft furniture and stainless steel do not say. Plate furniture are: medium density fiberboard or particleboard they are made of glue and cold pressed from. Surface paste veneer, trimethine ammonia kraft paper, brush paint. ?? To the mall to buy a furniture are generally divided into two kinds: 1 is made of medium density fiberboard .2 is made of particleboard. (Granular wood pressed from the system)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel bar truss floor deck

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords