Staple Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Properties of Staple fibers needle punched non woven geotextile

Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

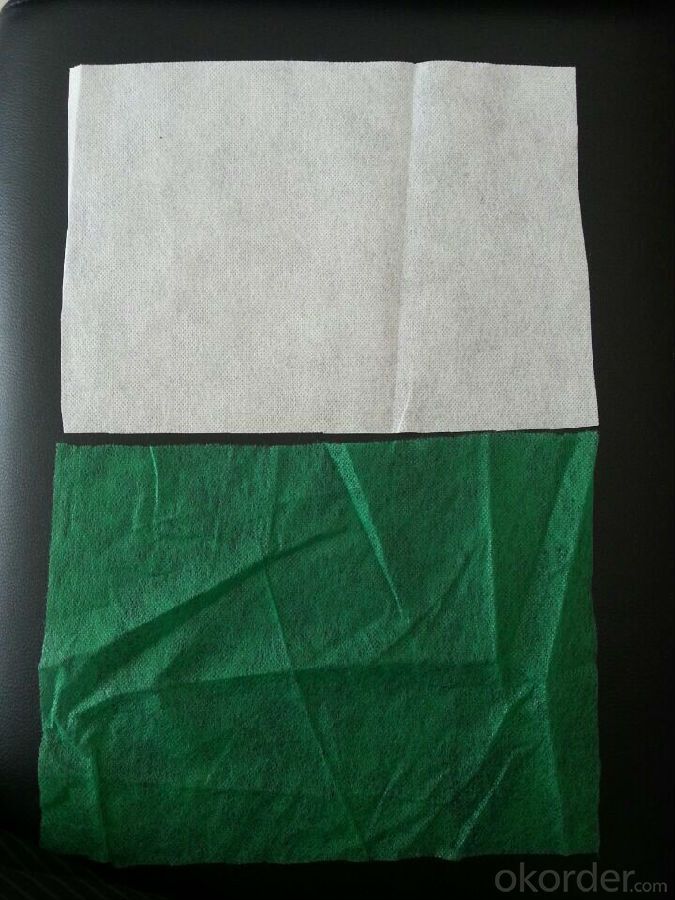

Images of non woven geotextile

- Q:Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q:Can geotextiles be used in railway track bed stabilization?

- Yes, geotextiles can be used in railway track bed stabilization. They are commonly used to improve the stability and performance of the track bed by providing separation, filtration, and reinforcement. Geotextiles help to prevent the mixing and migration of different layers of the track bed, enhance drainage, increase load-bearing capacity, and reduce the risk of track settlement and deformation. Overall, geotextiles play a crucial role in maintaining the long-term stability and durability of railway tracks.

- Q:Geotextile mouth chain suture is what kind of picture

- Hello I am a professional geotextile and other geotextile materials,

- Q:How do geotextiles contribute to sediment control?

- Geotextiles contribute to sediment control by acting as a barrier that prevents the erosion and transport of sediment. They are placed in areas where sediment runoff is a concern, such as construction sites or areas prone to erosion. The geotextiles help to stabilize the soil and prevent sediment from being carried away by water or wind, thereby protecting nearby water bodies and ecosystems from sediment pollution.

- Q:What are the different geotextile filtration testing methods?

- There are several different geotextile filtration testing methods, including the gradient ratio test, the constant head test, the falling head test, and the sand column test. These tests are conducted to evaluate the ability of geotextiles to filter out fine particles from water or other fluids, and to assess their performance in various filtration applications.

- Q:What are the applications of geotextiles in civil engineering?

- Geotextiles have various applications in civil engineering, including soil stabilization, erosion control, filtration, drainage, and reinforcement. They are used to prevent soil erosion on slopes and embankments, provide filtration and separation in road construction, improve the performance of retaining walls and landfills, and enhance the durability of pavements. Geotextiles also play a crucial role in environmental protection by preventing soil contamination and promoting sustainable construction practices.

- Q:300 grams of non-woven geotextile piercing strength is how much

- First of all, according to what you said 300g non-woven geotextile should be polyester staple fiber non-woven geotextile. Polyester staple fiber non - woven geotextile implementation of the national standard GB / T - 2008 standard. According to GB / T-2008 standard anti-puncture strength (standard is CBR burst strength) requirements, 300g national standard geotextile anti-piercing strength should be ≥ 1.5KN.

- Q:How do geotextiles contribute to green building certifications?

- Geotextiles contribute to green building certifications by providing sustainable and environmentally friendly solutions. They can be used in various applications such as erosion control, stormwater management, and soil stabilization. By utilizing geotextiles, green building projects can achieve high performance in areas like water efficiency, site selection, and construction waste reduction. Additionally, geotextiles promote the use of recycled materials, reduce the need for harmful chemicals, and enhance energy efficiency, all of which are key factors in obtaining green building certifications.

- Q:Woven geotextile is not considered a spinning geotextile

- Woven geotextile is made of textile technology is a spinning geotextile.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Staple Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords