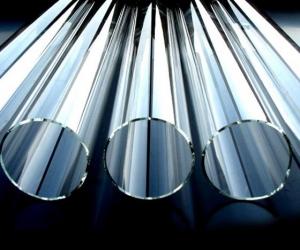

Standard Quartz Crucible

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000Pcs pc

- Supply Capability:

- 10000PIECE PER MONTH pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Standard Quartz Crucible

| Packaging Detail: | standard export packing |

| Delivery Detail: | 7-10days |

Specifications of Standard Quartz Crucible

1.all kinds crucible

2.make as your drawing

3.high corrosion resistance

4.high quality,no bubble,no airline

Features of Standard Quartz Crucible

1.Extraordinary Reliability - Thermo Materials' ISO 9000 quality system mandates 100% inspection using assisted visual, ultrasonic and other quality assurance techniques for crucibles

2.Outstanding Thermal Shock Resistance - fused silica maintains the lowest coefficient of thermal expansion of any commercially available material

3.Excellent Refractoriness - reliable performance to extreme temperatures and pressures.

4.Application: Fused silica crucibles are used in the manufacture of poly-crystalline silicon solar cells, an important energy source for the future.

- Q:What are the sizes of arc quartz crucibles?

- HF can not contact, high temperature, easy and caustic alkali carbonate reaction and alkali metal. 3. quartz crucibles are suitable for melting samples with K2S2O7, KHSO4 as flux, and using Na2S207 (first drying at 212 degrees) to treat samples with flux.

- Q:Can porcelain crucible, quartz crucible and alumina crucible be filled with aluminium hydroxide?

- The translucent quartz crucible made by arc method is the basic material for drawing large diameter monocrystalline silicon and developing large-scale integrated circuit

- Q:Is the quartz crucible drawn by monocrystalline silicon disposable?

- One must, one pot, 3000 pieces! Or made in China?

- Q:The quartz ceramic crucible melting quartz crucible

- Because of the use of extremely harsh conditions, the crucible of purity, strength, appearance defects, internal quality, high temperature performance, thermal shock stability and dimensional accuracy has very strict requirements.

- Q:What's the difference between a quartz crucible and a porcelain crucible?

- The quartz crucible is white and transparent, and the opal crucible is used below 1200 degrees. The transparent crucible is used below 1400 degrees. The ceramic crucible is used at 1400-1600 degreesThe quartz crucible is resistant to acid and alkali, but hydrofluoric acid is not availableCeramic crucible does not resist strong alkali

- Q:A brief introduction to quartz crucibles

- In addition to HF, ordinary dilute inorganic acids can be used as cleaning solutions. Quartz crucibles used for drawing monocrystalline silicon in China are 18 inches and 20 inches 22 inches. There are also 22 or more crucibles used by manufacturers. At present, the crucible technology produced by large crucible manufacturers in China is quite mature. Its production and use of raw materials, quartz sand imported by the United States and Norway high purity quartz sand two. There are also small factories using homemade materials. The quartz crucibles produced by their raw materials have certain influence on the stability of the drawn monocrystalline silicon.The current production of crucible coating technique has been used by most manufacturers is in ordinary quartz sand solution for crucible surface coated with a layer of two barium oxide solution so as to form a dense layer, the dense layer can prevent the silicon and silicon high temperature quartz crucible drawing process to improve reaction rate.

- Q:What happens when carbon carbon crucibles are cracked?

- The R corner is part of gravity and expansion forces;

- Q:At present, the quartz crucible used in Czochralski silicon is used to make use of barium coating, but how does the oxygen content rise when the coating react with the silicon melt?

- First of all, the main source of oxygen is the fusion of silicon and quartz crucible, 99% of oxygen volatilization, and 1% of the growth of single crystal into the silicon bar, so it has nothing to do with the coating, unless the crucible is not, but not possible

- Q:Can quartz crucibles be used as ROI for fluorine compounds?

- It has the advantages of high purity, strong heat resistance, large size, high precision, good heat insulation, energy saving, stable quality and so on; and not HF contact, high temperature, easy and caustic alkali carbonate reaction and alkali metal; quartz crucible suitable for K2S2O7, KHSO4 and Na2S207 as flux melted samples (the first in 212 the degree of drying) as flux sample; quartz brittle, easily broken, use caution; in addition to Hf, the ordinary dilute inorganic acid can be used as a cleaning fluid. Corundum crucible: corundum crucible is composed of porous fused alumina, hard and refractory; corundum crucible for melting flux samples with anhydrous Na2C03 and some alkaline substances, not suitable for use in Na 202 and NaOH strong alkaline substances and acidic substances as flux (as K2S 207) melt sample.

- Q:Why are fused quartz transparent and opaque?

- China referred to as quartz glass, press process, use and appearance to the classification, such as transparent fused quartz glass, fused quartz glass, quartz glass, synthetic gas semltime quartz glass, opaque quartz glass, quartz glass, quartz glass, semiconductor electric light source with quartz glass.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 2000 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Indian:South Asian;Japan |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 60% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English;Chinese;Japanese |

| b)Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 8 line |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Standard Quartz Crucible

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000Pcs pc

- Supply Capability:

- 10000PIECE PER MONTH pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords