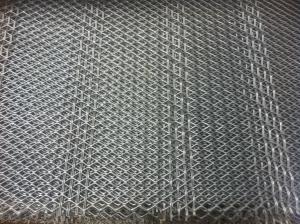

Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

201,202,302,304,304L,316,316L

Guage:

1.wire diameter:0.1-3.0mm

2.Mesh: 1-650mesh.

3.Width:0.5-5m

3.Length:30m

Weave way

Dutch weave

Plain weave

Twill weave

Stainless steel wire mesh kind:

1, stainless steel plain weave mesh. 2, stainless steel twill mesh. 3, stainless steel mesh bamboo pattern. 4, five mechanized stainless steel mesh. 5, stainless steel perforated metal mesh. 6, stainless steel crimped wire mesh. 7, stainless steel chain link fence. 8, stainless steel mesh. 9, stainless steel welded wire mesh. 10, stainless steel hexagonal. 11, stainless steel I-Net. 12, stainless steel wire meshes. 13, stainless steel mine screen. 14 mesh stainless steel shells.

- Q:What is the role of steel pipes in the construction of bridges and tunnels?

- Steel pipes play a vital role in the construction of bridges and tunnels as they provide structural support and durability. They are commonly used for the fabrication of the framework and foundation of these infrastructures. Steel pipes offer high tensile strength, corrosion resistance, and the ability to withstand heavy loads, making them an ideal choice for ensuring the integrity and longevity of bridges and tunnels. Additionally, steel pipes can be easily welded, allowing for efficient and cost-effective construction methods.

- Q:How do you determine the required support spacing for steel pipes?

- The required support spacing for steel pipes is determined based on several factors including the pipe material, size, weight, and operating conditions. Generally, industry standards and guidelines such as those provided by the American Society of Mechanical Engineers (ASME) are followed to calculate the appropriate spacing. These standards take into account factors such as pipe deflection, thermal expansion, vibration, and load-bearing capacity to ensure the pipes are adequately supported and do not experience excessive stress or deformation.

- Q:Seamless steel pipe and welded pipe what is the difference?

- The welded pipe is made directly from the stainless steel band by machine, and it is made of round steel or perforated by Guan Pi

- Q:What are the common applications of steel pipes in industrial settings?

- Steel pipes are commonly used in industrial settings for various applications such as transporting fluids and gases, providing structural support in construction projects, conveying materials in manufacturing processes, and facilitating the distribution of water, oil, and gas in pipelines.

- Q:What are the different types of pipe fittings used with steel pipes?

- There are several types of pipe fittings commonly used with steel pipes, including elbows, tees, reducers, flanges, couplings, and unions.

- Q:Where is the difference between seamless steel pipe and welded pipe?

- In appearance, seamless steel pipe and welded steel pipe difference in the welded pipe wall welded tendons, and seamless No.

- Q:DN150 welded steel tubes one meter multiple

- The theoretical weight table of welded steel pipe (Kg) can be checked, and the outer diameter and wall thickness can be measured according to the formula.For example: DN150 welded steel pipe, diameter 165mm, thickness 4.5mm, weight kg per meter.Welded steel pipe theoretical weight (Kg/m) = (165-4.5) * 4.5 * 0.02466=17.81Kg

- Q:Can steel pipes be used for structural purposes?

- Yes, steel pipes can be used for structural purposes.

- Q:Can steel pipes be used for conveying abrasive slurries?

- Yes, steel pipes can be used for conveying abrasive slurries. Steel pipes are known for their durability and strength, making them suitable for handling abrasive materials such as slurries. However, to ensure longevity and prevent excessive wear, it is important to select the appropriate grade of steel and consider factors such as pipe thickness, lining options, and flow velocity. Additionally, implementing proper maintenance and inspection procedures can help to detect and address any wear or corrosion that may occur over time.

- Q:What is the bending strength of steel pipes?

- The bending strength of steel pipes can vary depending on factors such as the grade and thickness of the steel, as well as the specific manufacturing process. However, in general, steel pipes are known for their high bending strength due to the inherent strength and durability of the material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords