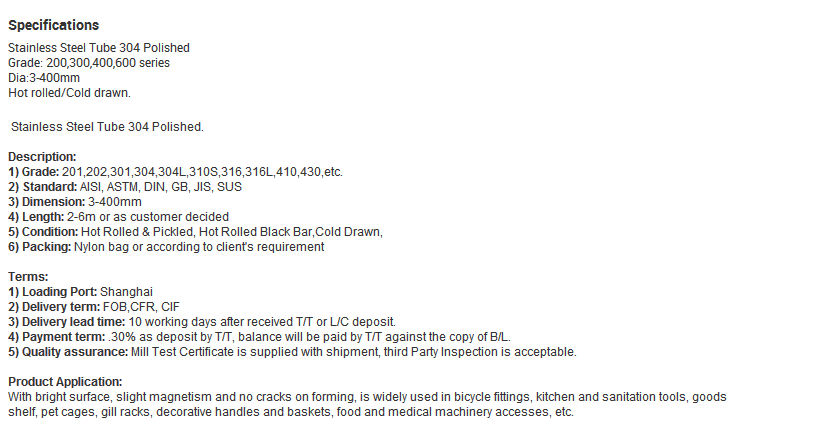

Stainless Steel Tube 304/316L Polished Welded Seamless Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What are the factors to consider when selecting stainless steel pipes?

- There are several factors to consider when choosing stainless steel pipes: 1. Take into account the grade of stainless steel. Different grades offer varying levels of corrosion resistance, strength, and durability. It is crucial to select the appropriate grade based on the specific application and environmental conditions. 2. Ensure that the size and dimensions of the stainless steel pipes are suitable for the intended use. Consider factors such as inner diameter, outer diameter, wall thickness, and length to guarantee a proper fit and compatibility with the existing system. 3. Evaluate the corrosion resistance of the stainless steel pipes. While stainless steel is known for its excellent corrosion resistance properties, different grades provide varying levels of protection. Take into account the exposure to corrosive substances and choose a grade that can withstand the specific environment. 4. Consider the pressure and temperature requirements. Stainless steel pipes are commonly used in high-pressure and high-temperature applications. It is crucial to select a grade that can handle the required pressure and temperature without compromising the pipe's structural integrity. 5. Assess the fabrication and installation requirements. When choosing stainless steel pipes, take into consideration the ease of fabrication and installation. Some grades may require special welding techniques or pre-fabrication processes, so it is important to evaluate the feasibility and cost-effectiveness of such requirements. 6. Keep the cost in mind. The cost of stainless steel pipes can vary depending on the grade, size, and other factors. It is important to consider the budget and find a balance between cost and desired quality and performance. 7. Ensure compliance with regulatory and industry standards. Depending on the application, there may be specific standards and regulations that need to be met. Make sure that the selected stainless steel pipes comply with these standards to ensure safety and reliability. By considering these factors, one can make an informed decision when selecting stainless steel pipes that meet the specific requirements of their application.

- Q:What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or unevenness on the inner surface of the pipes, which can affect the flow of fluids or gases through the pipes. It is typically measured in terms of roughness coefficients or Ra values, indicating the average height of irregularities on the pipe's interior.

- Q:How do you test the quality of stainless steel pipes?

- There are several ways to test the quality of stainless steel pipes. One common method is visual inspection, where the pipes are examined for any surface defects, such as cracks, pits, or irregularities. Another method involves conducting non-destructive tests, such as ultrasonic or X-ray examinations, to detect any internal flaws or defects. Additionally, chemical analysis can be performed to verify the composition and grade of the stainless steel, ensuring it meets the required standards. Mechanical testing, such as tensile and hardness tests, can also be conducted to evaluate the strength and durability of the pipes. Overall, a combination of these testing methods is typically employed to ensure the quality of stainless steel pipes.

- Q:What are the different types of stainless steel pipe tees?

- There are several different types of stainless steel pipe tees, each designed for specific applications and requirements. 1. Equal Tee: This type of tee has three outlets of the same size, forming a 90-degree angle. It is commonly used to branch off or combine flow in a pipeline with equal diameters. 2. Reducing Tee: As the name suggests, a reducing tee has one outlet smaller than the other two. It is used to connect pipes of different sizes, allowing for a smooth transition in the flow of fluids or gases. 3. Barred Tee: This tee has a bar welded across the branch opening, providing additional support and reinforcement. It is commonly used in high-pressure or high-temperature applications to prevent stress concentration and potential failure. 4. Lateral Tee: A lateral tee has one outlet at a 45-degree angle, allowing for a branch connection at a different direction. It is often used in situations where a pipeline needs to be diverted or connected at an angle. 5. Cross Tee: A cross tee has four outlets forming a cross-shaped configuration. It is used when there is a need to split or combine flow in multiple directions, commonly found in complex piping systems. 6. Unions and Socket Weld Tee: These types of tees have sockets or unions at the branch connection, allowing for easy disassembly and maintenance. They are often used in applications where regular inspection, cleaning, or replacement is required. 7. Threaded Tee: Threaded tees have threaded branch connections, which can be screwed onto the pipe without the need for welding. They are commonly used in low-pressure applications or when frequent disassembly is required. Each type of stainless steel pipe tee offers specific advantages and is selected based on the requirements of the particular piping system, such as flow rates, pressure, temperature, and compatibility with the fluids or gases being transported.

- Q:Can stainless steel pipes be used for underground irrigation systems?

- Yes, stainless steel pipes can be used for underground irrigation systems. Stainless steel is highly resistant to corrosion, making it a durable and long-lasting option for underground applications. It can withstand the moisture and soil conditions typically found in irrigation systems, ensuring reliable and efficient water distribution.

- Q:What is the difference between stainless steel pipes and PVC pipes?

- Stainless steel pipes are made from a durable and corrosion-resistant material, while PVC pipes are made from a lightweight and cost-effective plastic. Stainless steel pipes are suitable for high-pressure and high-temperature applications, while PVC pipes are commonly used for water supply and drainage systems. Additionally, stainless steel pipes have a longer lifespan and can withstand harsh environmental conditions, whereas PVC pipes may degrade over time and are more prone to cracking or breaking.

- Q:Can stainless steel pipes be used for seawater applications?

- Yes, stainless steel pipes can be used for seawater applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of seawater, making it an ideal material for pipes used in marine environments. The chromium content in stainless steel forms a protective oxide layer on the surface of the pipes, preventing corrosion and ensuring durability. Additionally, stainless steel pipes have good strength and can handle high-pressure situations, making them suitable for various seawater applications such as desalination plants, offshore oil rigs, and shipbuilding.

- Q:Can stainless steel pipes be used for pharmaceutical manufacturing?

- Yes, stainless steel pipes can be used for pharmaceutical manufacturing. Stainless steel is a commonly used material in the pharmaceutical industry due to its excellent corrosion resistance, high strength, and ease of sterilization. It is suitable for transporting various pharmaceutical fluids and gases while ensuring cleanliness, safety, and compliance with industry regulations.

- Q:How long do stainless steel pipes last?

- Stainless steel pipes have an impressive lifespan and can last for several decades, depending on various factors such as the quality of the steel, installation techniques, and maintenance practices. In general, with proper care and maintenance, stainless steel pipes can last 50 years or more.

- Q:Can stainless steel pipes be used for sewage and wastewater systems?

- Indeed, sewage and wastewater systems can make use of stainless steel pipes. Stainless steel is renowned for its exceptional resistance to corrosion, rendering it highly suitable for water and sewage-related purposes. Its ability to withstand rust, corrosion, and chemical reactions ensures an extended lifespan while reducing the necessity for frequent replacements. Moreover, stainless steel pipes possess a smooth surface that hinders the accumulation of debris and facilitates effortless cleaning. Furthermore, stainless steel is impermeable, preventing the growth of harmful bacteria and fungi, thus contributing to its hygienic nature and suitability for sewage and wastewater systems. The durability, dependability, and capacity to withstand harsh environmental conditions make stainless steel pipes a favored choice for such applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Tube 304/316L Polished Welded Seamless Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords